Expansion-prevention plastic chemical barrel

A chemical barrel and plastic technology, applied in containers, packaging, transportation and packaging, etc., can solve the problems of aging and rupture, easy deformation, barrel expansion, etc., to eliminate potential safety hazards, avoid expansion or even explosion, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

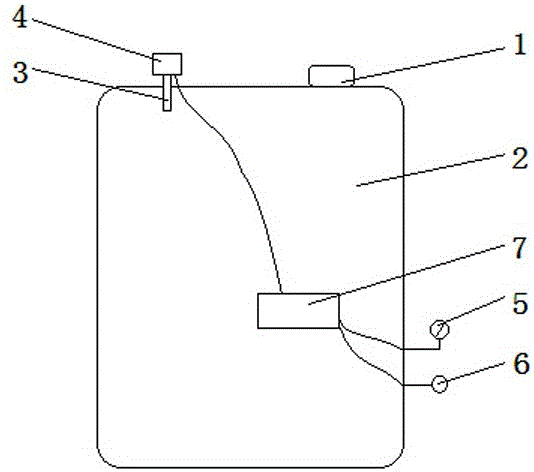

[0016] see figure 1 , figure 1 It is a structural schematic diagram of an anti-expansion plastic chemical barrel according to the present invention, including a barrel cover 1 and a barrel body 2. A pressure relief hole 3 is opened on the top of the barrel body 2, and a pressure relief hole 3 is provided on the pressure relief hole 3. Valve 4, the lower part of the barrel body 2 is provided with a pressure gauge 5 and an alarm display lamp 6 respectively, the surface of the barrel body 2 is provided with a control device 7, and the control device 7 is connected with the pressure gauge 5 and the alarm display lamp respectively through lines. 6 and pressure relief valve 4 are connected.

[0017] In addition, the bottom of the pressure relief valve 4 is provided with a sealing ring.

[0018] Furthermore, the barrel cover 1 and the barrel body 2 are flexibly connected by threads.

[0019] Moreover, the inner wall of the barrel body 2 is provided with an anti-corrosion coating. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com