A suction anchor device

A rod device, suction anchor technology, applied in construction, excavation, infrastructure engineering and other directions, can solve the problems of increased safety risk, small total resistance, high water content, improve stability and safety, increase anchor rod Side friction resistance, the effect of improving the side friction resistance of the bolt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

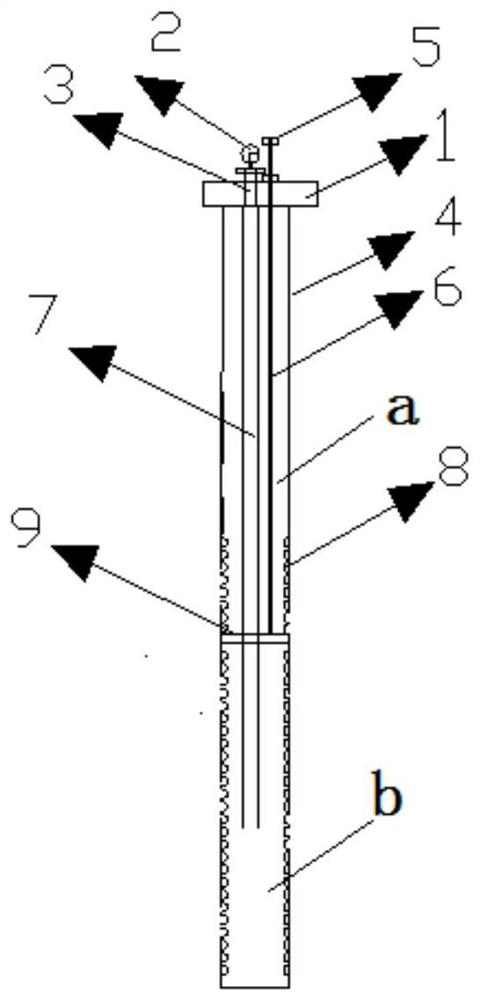

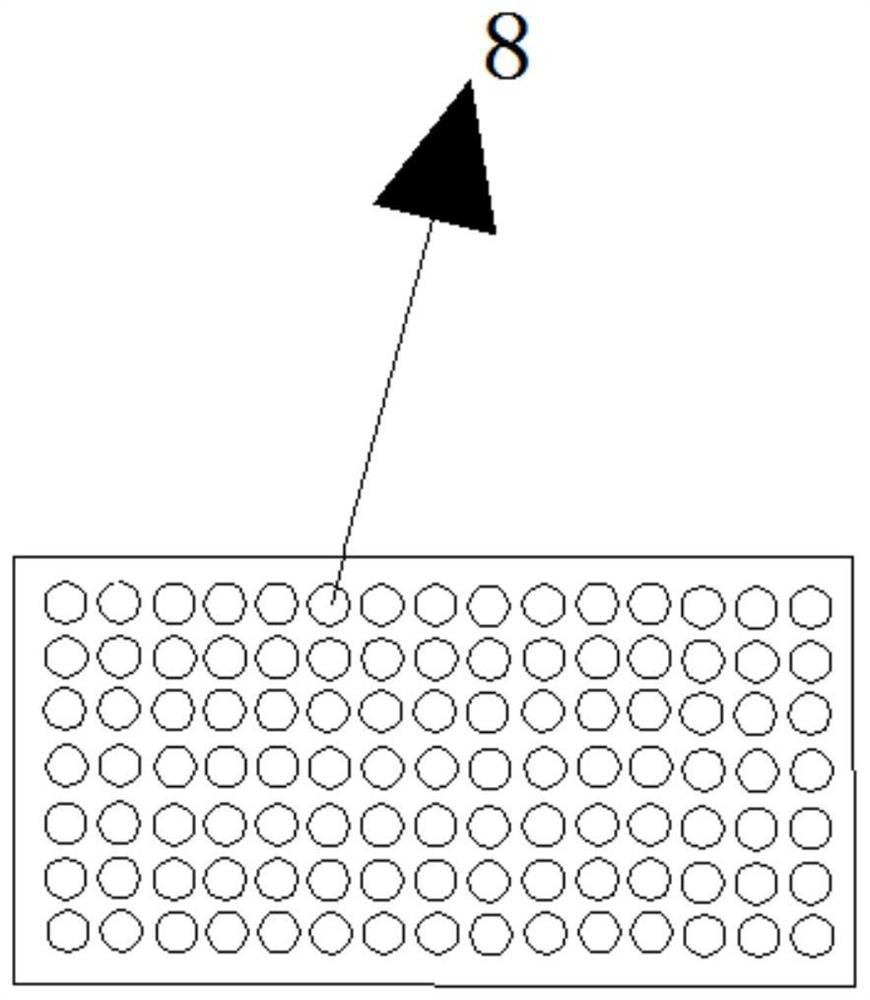

[0019] Referring to the drawings, a suction anchor rod device includes a hollow cylindrical anchor rod 4, the bottom port of the anchor rod 4 is sealed, and the top port of the anchor rod 4 is equipped with a sealing cover plate 1, and the sealing cover plate 1 and the The anchor rod 4 is detachably connected; a section of the anchor rod 4 close to the bottom port is defined as the bottom section, the end close to the top port is the top section, and a number of sieve holes 8 are distributed on the side wall of the bottom section of the anchor rod 4, The sieve hole 8 is communicated with the inner cavity of the anchor rod 4; the anchor rod 4 is provided with a lifting plate 9, and the lifting plate 9 can be moved up and down along the axial direction of the anchor rod 4 through the lifting device and is arranged on the anchor rod 4. and the lifting plate 9 divides the inner cavity of the anchor rod 4 into an upper cavity a and a lower cavity b, and it is defined that the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com