Truck loading device of bagged materials

A material and fork technology, which is applied to the field of loading devices for bagged materials, can solve the problems of no positioning device, low efficiency, and deformation of the brackets in the packaging bag brackets, so as to reduce the labor intensity of loading and unloading, save warehouse area and specifications. unifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but this does not constitute a limitation to the protection scope of the present invention.

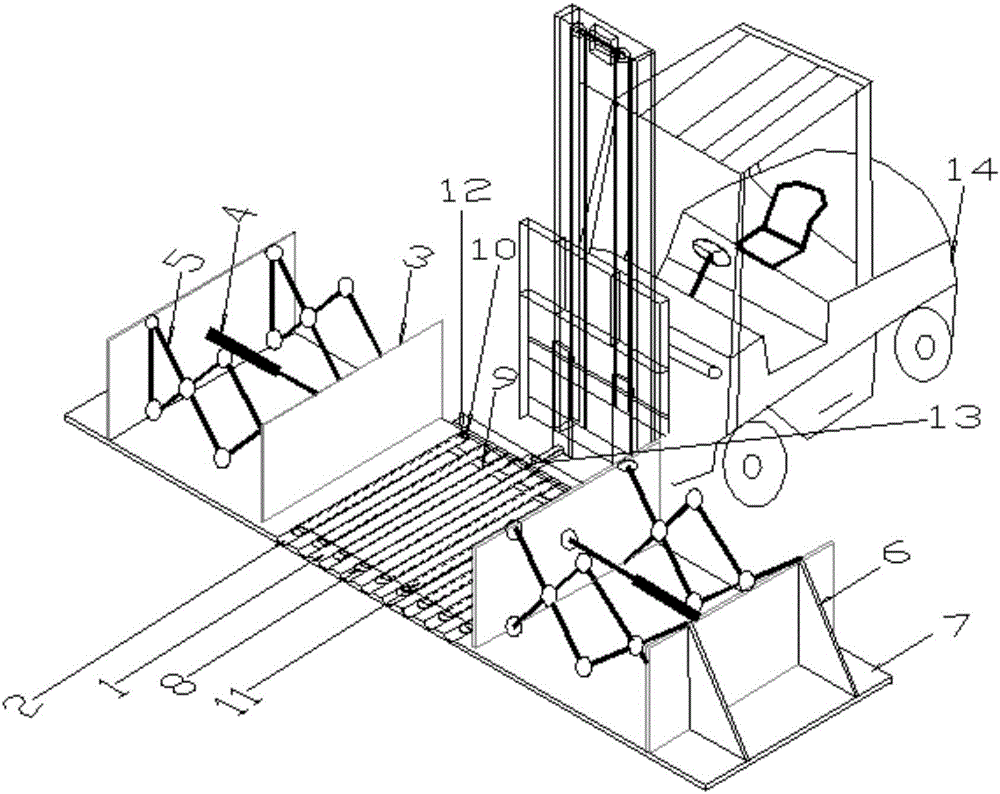

[0020] A loading device for bagged materials, including a forklift 14, the lifting frame of the forklift 14 is connected to the fork through the forklift insertion port 13, and also includes a bracket and a compression mechanism;

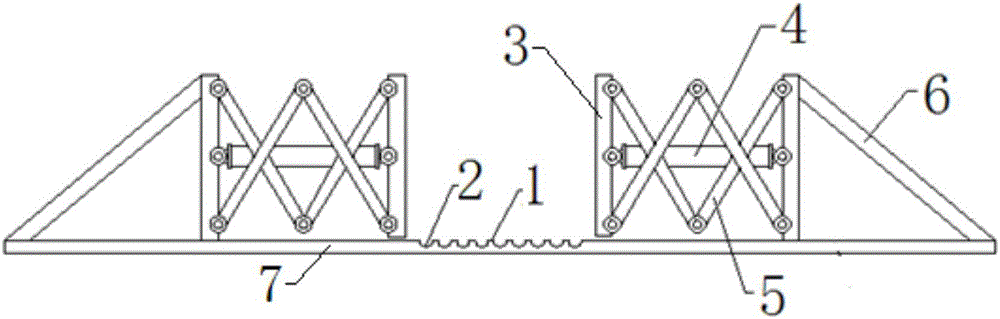

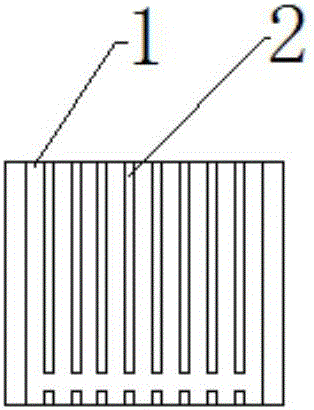

[0021] The bracket comprises a plurality of hollow steel pipes 8 arranged in parallel, and the tops of the plurality of hollow steel pipes 8 are all connected with a horizontal steel pipe 9, wherein the tops of the two hollow steel pipes 8 of the head and tail are provided with protrusions 10; A plurality of hollow steel pipes 8 can be inserted into the fork tines 11 of the fork; the roots of the two fork tines 11 at the head and tail of the fork are provided with first grooves 12 matching the protrusions 10 .

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com