Ferrite composition and electronic component

A technology of electronic components and ferrites, applied in transformer/inductor components, electrical components, circuits, etc., can solve the problems of large temperature change rate of inductance, inability to meet temperature characteristics, etc., achieve good temperature characteristics, and achieve miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

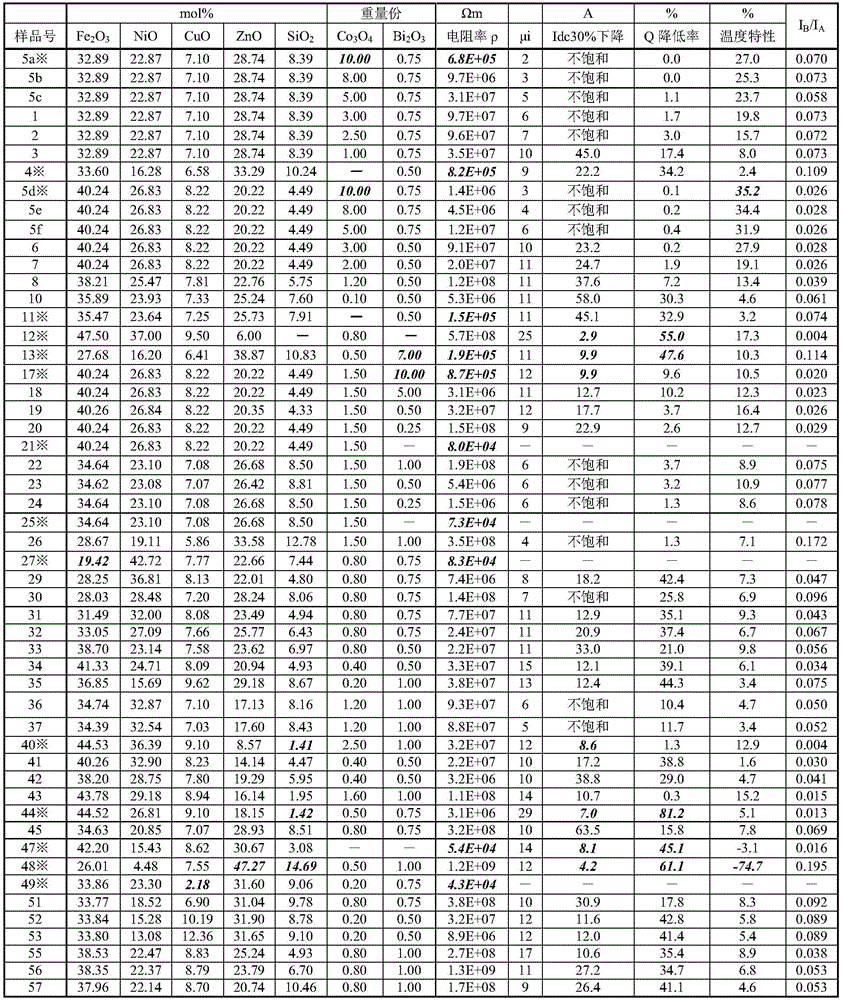

[0072] Hereinafter, the present invention will be described based on more detailed examples, but the present invention is not limited to these examples.

[0073] First, as a raw material of the main component, Fe 2 o 3 , NiO, CuO, ZnO, SiO 2 . Prepare Bi as a raw material for subcomponents 2 o 3 、Co 3 o 4 . In addition, the average particle diameter of the starting material is preferably 0.05 to 1.00 μm.

[0074] Next, the prepared main component raw material powder and auxiliary component raw material powder were weighed so that the sintered body had the composition described in Table 1.

[0075] After weighing, the Fe in the prepared main component raw material 2 o 3 , NiO, CuO, and if necessary, a part of ZnO was wet-mixed with a ball mill for 16 hours to obtain a raw material mixture.

[0076] Next, after drying the obtained raw material mixture, it calcined in air to obtain a calcined product. The calcining temperature is appropriately selected in the range of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com