Anti-siphon non-woven fabric and manufacturing method thereof

A manufacturing method and anti-siphon technology, applied in non-woven fabrics, textiles and papermaking, textile materials processing and other directions, can solve the problems of inability to meet outdoor equipment products, tensile force, tearing performance, tortuosity and waterproof performance, etc. Good waterproof effect, good bending performance, good waterproof performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An anti-siphon non-woven fabric, the raw materials of which include the following components in parts by weight: 60 parts of polyester fiber, 40 parts of low-melt cotton, polyester fiber includes two sizes of 16D×51mm and 6D×51mm, and the size of low-melt cotton is 4D ×51mm.

[0025] Wherein, the weight ratio of the two dimensions of 16D×51mm and 6D×51mm in the polyester fiber is 1:1.

[0026] The manufacture method of above-mentioned anti-siphon non-woven fabric, comprises the following steps:

[0027] (1) Opening: Mix the washing fiber and low-melt cotton according to the above ratio evenly and send them into the cotton storage box, and then send them into the opening machine for loosening and dissociation, so as to achieve uniform opening;

[0028] (2) Carding: the opened raw material obtained in step (1) is sent into a carding machine to be carded into a net;

[0029] (3) Laying: the cotton web obtained in step (2) is laminated to 20 or more layers by a web-laying...

Embodiment 2

[0041] An anti-siphon non-woven fabric, the raw materials of which include the following components in parts by weight: 70 parts of polyester fiber, 30 parts of low-melt cotton, polyester fiber includes two sizes of 16D×51mm and 6D×51mm, and the size of low-melt cotton is 4D ×51mm.

[0042] Wherein, the weight ratio of the two dimensions of 16D×51mm and 6D×51mm in the polyester fiber is 1:1.5.

[0043] The manufacture method of above-mentioned anti-siphon non-woven fabric, comprises the following steps:

[0044] (1) Opening: Mix the washing fiber and low-melt cotton according to the above ratio evenly and send them into the cotton storage box, and then send them into the opening machine for loosening and dissociation, so as to achieve uniform opening;

[0045] (2) Carding: the opened raw material obtained in step (1) is sent into a carding machine to be carded into a net;

[0046] (3) Laying: the cotton web obtained in step (2) is laminated to 20 or more layers by a web-layi...

Embodiment 3

[0055] An anti-siphon non-woven fabric, the raw materials of which include the following components in parts by weight: 50 parts of polyester fiber, 50 parts of low-melt cotton, polyester fiber includes two sizes of 16D×51mm and 6D×51mm, and the size of low-melt cotton is 4D ×51mm.

[0056] Wherein, the weight ratio of the two dimensions of 16D×51mm and 6D×51mm in the polyester fiber is 1:2.

[0057] The manufacture method of above-mentioned anti-siphon non-woven fabric, comprises the following steps:

[0058] (1) Opening: Mix the washing fiber and low-melt cotton according to the above ratio evenly and send them into the cotton storage box, and then send them into the opening machine for loosening and dissociation, so as to achieve uniform opening;

[0059] (2) Carding: the opened raw material obtained in step (1) is sent into a carding machine to be carded into a net;

[0060] (3) Laying: the cotton web obtained in step (2) is laminated to 20 or more layers by a web-laying m...

PUM

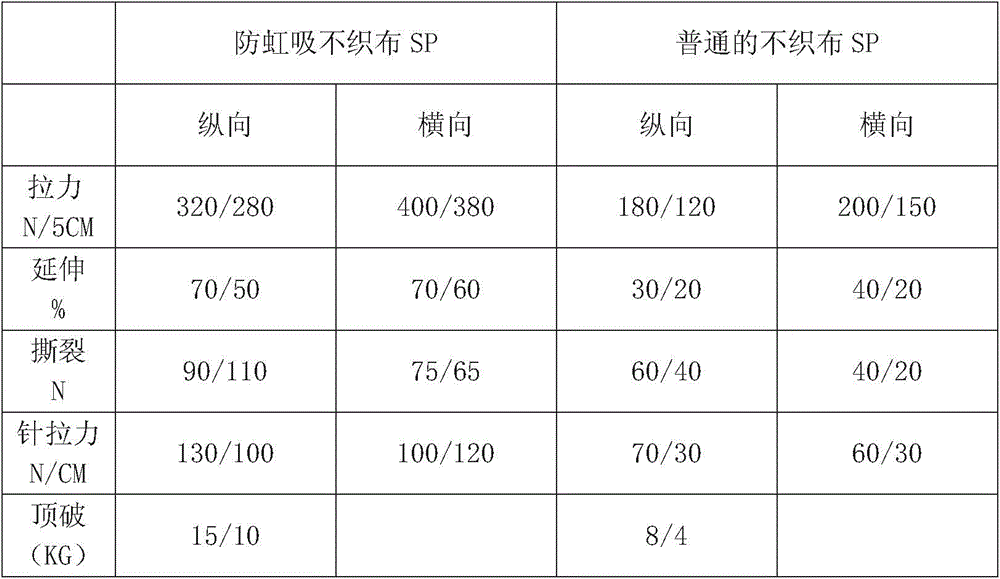

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tension | aaaaa | aaaaa |

| Lateral tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com