High-flame-retardance anti-rat-biting center pipe type optical cable

A central tube type, anti-rat bite technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of reduced structural strength of optical cables, squirrel bites of optical cables, structural instability, etc., to overcome low structural strength and good bending performance. , the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

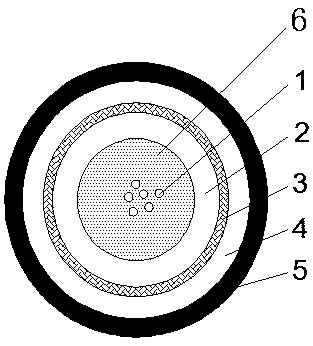

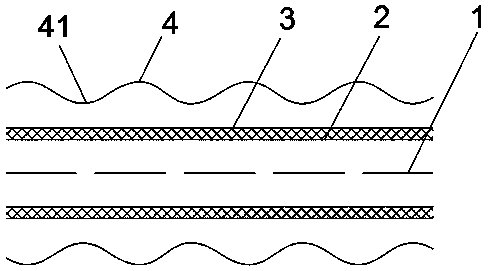

[0018] Such as Figure 1-2 As shown, a high flame-retardant rodent-proof central tube type optical cable, the optical cable includes an optical fiber 1, a central tube 2, a glass fiber tape 3, an aluminum alloy tube 4, and an outer sheath layer 5 from the inside to the outside; The optical fiber 1 is placed in the central tube 2 and arranged along the length direction of the central tube 2; the optical cable 1 adopts a single-mode optical fiber, and the central tube 2 is made of polybutylene terephthalate; the interior of the central tube 2 Fill the fiber paste 6, the fiber paste 6 squeezes the optical fiber 1 in the center; the center tube 2 is wrapped with a layer of glass fiber tape 3, the thickness of the glass fiber tape 3 is 0.2 mm, and the thickness of the glass fiber tape 3 on the surface of the center tube is controlled. The overlap rate is 30%; the aluminum alloy tube 4 is arranged outside the glass fiber band 3, and the alloy tube 4 is bonded around the glass fiber ...

Embodiment 2

[0021] Such as Figure 1-2 As shown, a high flame-retardant rodent-proof central tube type optical cable, the optical cable includes an optical fiber 1, a central tube 2, a glass fiber tape 3, an aluminum alloy tube 4, and an outer sheath layer 5 from the inside to the outside; The optical fiber 1 is placed in the central tube 2 and arranged along the length direction of the central tube 2; the optical cable 1 adopts a light beam, and the light beam contains 20 optical fibers, and the central tube 2 is made of polypropylene; the central tube 2. The inside is filled with fiber paste 6, and the fiber paste 6 squeezes the optical fiber 1 at the center; the center tube 2 is wrapped with a layer of glass fiber tape 3, and the thickness of the glass fiber tape 3 is 0.2mm. The overlapping rate of the surface is 20%; the aluminum alloy tube 4 is arranged outside the glass fiber band 3, and the alloy tube 4 is bonded by the aluminum alloy band around the glass fiber band 3 to form a cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com