Anti-siphon multi-layer non-woven fabric and preparation method thereof

A non-woven fabric and anti-siphon technology, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of reduced joint force of non-woven fabrics, decreased strength of non-woven fabrics, and decreased water resistance of non-woven fabrics, so as to achieve water resistance With improved strength, strong tear performance and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

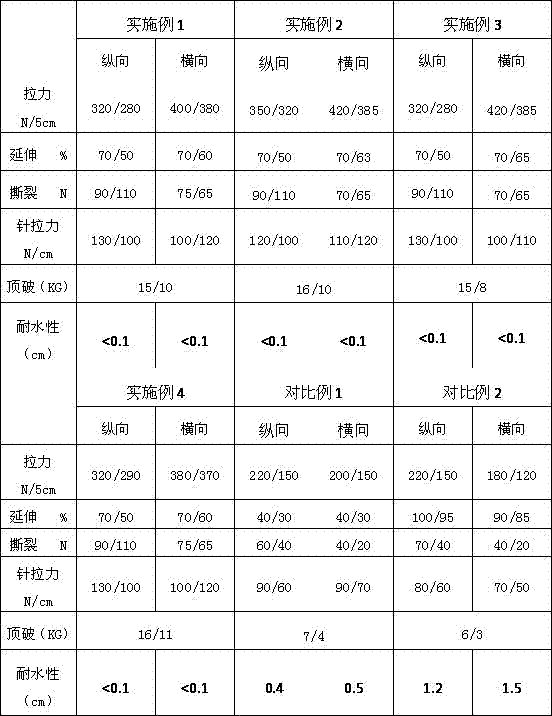

Examples

Embodiment 1

[0028] Anti-siphon multi-layer non-woven fabric, the raw materials are calculated by mass percentage, including 70% polyester fiber and 30% low-melt cotton, the diameter of the polyester fiber is 1.5~15μm, and the length is 51~56mm; the low-melt cotton The diameter is 2-4μm, and the length is 51~56mm.

[0029] Among them, the polyester fiber is composed of fibers with a diameter of 1.5 μm and a length of 51 mm and fibers with a diameter of 3 μm and a length of 51 mm in a mass ratio of 3:7. The low-melt cotton is composed of low-melt cotton with a diameter of 3 μm and a length of 51 mm and low-melt cotton with a diameter of 4 μm and a length of 56 mm in a mass ratio of 1:3.

Embodiment 2

[0031] Anti-siphon multi-layer non-woven fabric, the raw materials are calculated by mass percentage, including 50% polyester fiber and 50% low-melt cotton, the diameter of the polyester fiber is 1.5~15μm, and the length is 51~56mm; the low-melt cotton The diameter is 2-4μm, and the length is 51~56mm.

[0032] Wherein, the polyester fiber is a fiber with a diameter of 7.8 μm and a length of 54 mm, a fiber with a diameter of 1.5 μm and a length of 51 mm and a fiber with a diameter of 3 μm and a length of 51 mm in a mass ratio of 4:3:3. The low-melt cotton is composed of low-melt cotton with a diameter of 3 μm and a length of 51 mm and low-melt cotton with a diameter of 4 μm and a length of 56 mm in a mass ratio of 1:3.

Embodiment 3

[0034] Anti-siphon multi-layer non-woven fabric, the raw materials are calculated by mass percentage, including 60% polyester fiber and 40% low-melt cotton, the diameter of the polyester fiber is 1.5~15μm, and the length is 51~56mm; the low-melt cotton The diameter is 2-4μm, and the length is 51~56mm.

[0035] Wherein, the polyester fiber is composed of fibers with a diameter of 1.5 μm and a length of 51 mm and fibers with a diameter of 15 μm and a length of 56 mm in a mass ratio of 3:7. The low-melt cotton is composed of low-melt cotton with a diameter of 3 μm and a length of 51 mm and low-melt cotton with a diameter of 4 μm and a length of 56 mm in a mass ratio of 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com