Device and method for automatically penetrating through rubber bar

A rubber rod and automatic threading technology, which is applied in the direction of erecting/assembling bridges, auxiliary forming equipment, bridges, etc., can solve the problems of insufficient clamping force of transmission sleeves, insufficient overall driving force, and low work efficiency indicators, achieving a small number, The performance is safe and reliable, and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

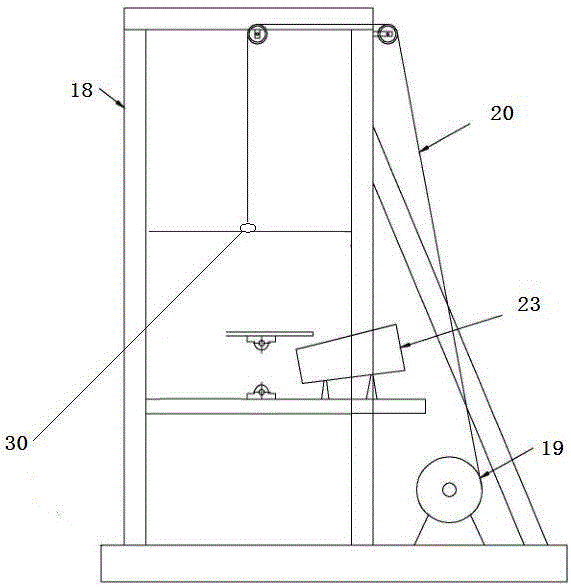

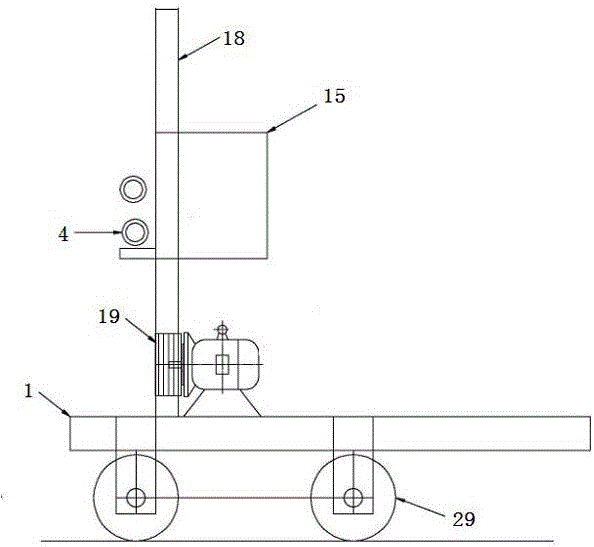

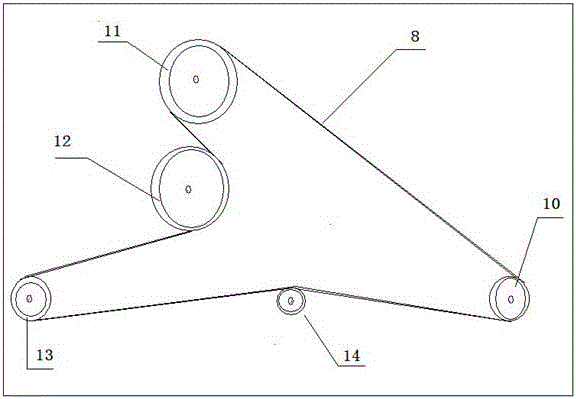

[0032] As shown in the figure, a device for automatically threading rubber rods provided by the present invention includes a support 1, a driving mechanism and a steel chuck 2, including an upper driving wheel 3 and a lower driving wheel 4, and the upper driving wheel 3 and the lower driving wheel 4. The upper and lower driving wheels are opposite and the axial directions are on the same vertical plane. The middle part of the upper driving wheel 3 and the lower driving wheel 4 has a concave arc 5. The two concave arcs are used to accommodate and clamp rubber rods. The driving motor drives the upper driving wheel 3 and the lower drive wheel 4 rotate simultaneously in the opposite direction. The steel chuck 2 is installed at the front end of the rubber rod, and the lower part of the steel chuck 2 is provided with a roller 6 and a telescopic supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com