Combined down hole hammer sealing and anti-loosening structure

A combined down-the-hole hammer and anti-loosening technology, which is applied in the direction of infrastructure engineering, drilling equipment, sheet pile walls, etc., can solve the problems that affect the installation accuracy of the impactor, poor anti-loosening effect, small contact area, etc., and achieve friction Good anti-loosening effect, tight fit, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

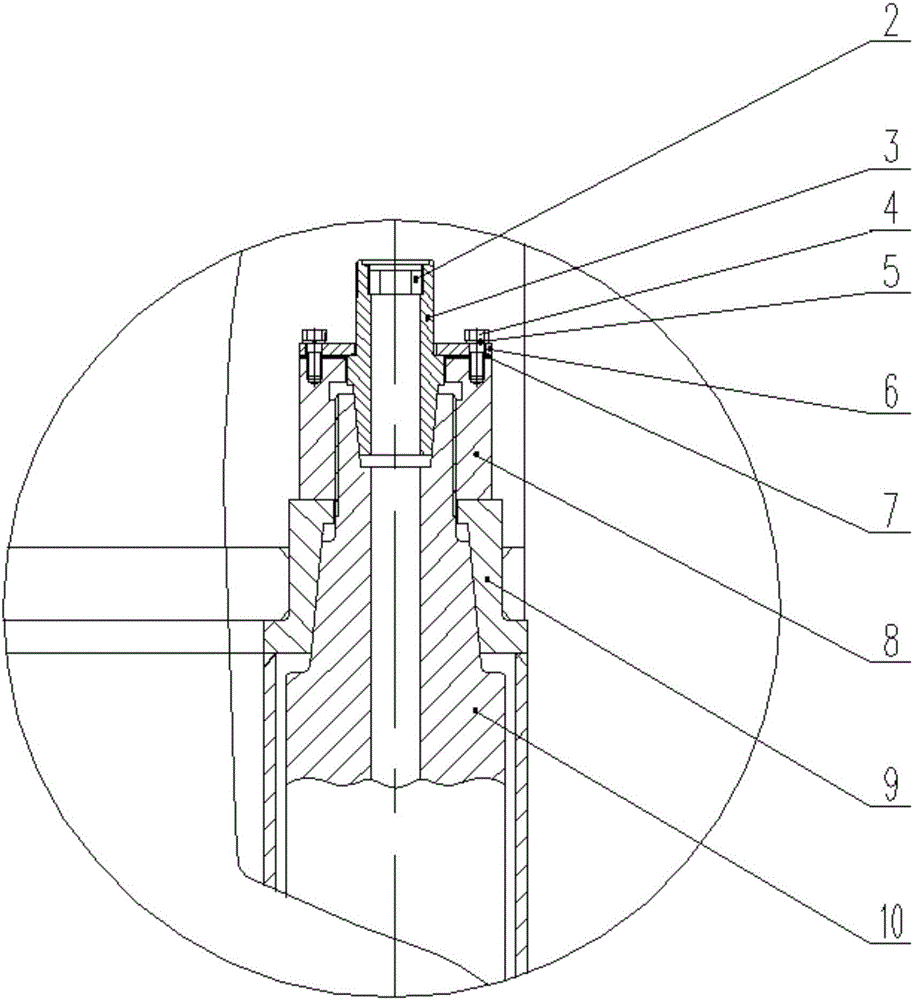

[0016] see figure 1 and figure 2 , insert the upper joint 10 of the impactor into the positioning taper sleeve 9, lock the upper joint 10 of the impactor with the round nut 8, put the nozzle 3 into the inner taper hole of the upper joint 10 of the impactor, seal the gasket 7 and The pressure plate 6 is set on the joint nozzle 3 in turn, the gasket 7 and the pressure plate 6 are connected to the round nut 8 with the bolt 4 and the spring washer 5, and the joint nozzle 3 is pressed down at the same time, and then the air hole damping adjustment device 2 is installed In the nozzle, it is used to adjust the intake air volume. When the combined down-the-hole hammer 1 is working, the compressed gas enters the upper joint 10 of the impactor through the nozzle 3. Since the nozzle 3 is in close contact with the conical surface of the taper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com