A Drilling Tool Using Turbine to Realize Rotating Impact

A technology for drilling tools and turbine rotors, which is applied to drilling equipment, driving devices for drilling in wellbore, earth-moving drilling, etc. Improve energy utilization and ensure the effect of effective transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

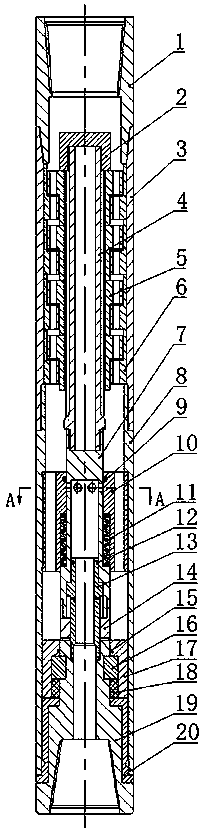

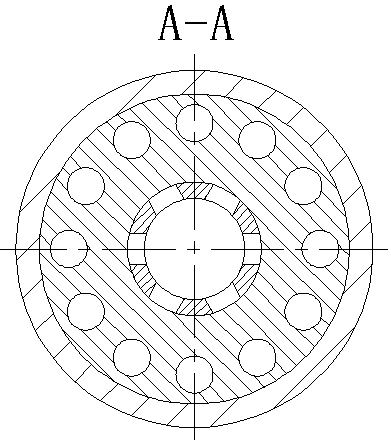

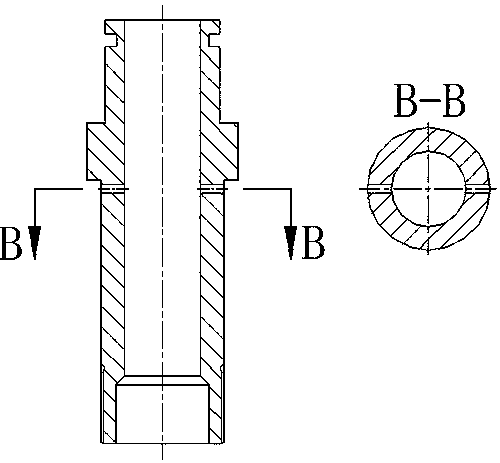

[0014] See attached figure 1 , a drilling tool that uses a turbine to achieve rotary impact, consisting of an upper joint 1, a nut 2, an upper casing 3, a turbine shaft 4, a turbine rotor 5, a turbine stator 6, a central tube 7, a lower casing 8, and a sleeve seal Ring 9, sleeve 10, disc spring 11, piston sealing ring 12, piston 13, hammer 14, clamping sleeve sealing ring 15, half ring 16, clamping sleeve 17, O-ring sealing ring 18, anvil 19 and Bafang The sleeve 20 is composed of the upper joint 1, the upper casing 3 and the lower casing 8, which are threaded in sequence, and after being fixed, a cavity is formed inside, and the cavity is followed by a nut 2, a turbine shaft 4, and a center Pipe 7, hammer 14, anvil 19; the upper end of the turbine shaft 4 is threadedly connected with the nut 2, and the lower end is threadedly connected with the center pipe 7; the turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com