A high frequency drilling hammer

An impactor and drilling technology, which is applied in drilling equipment, percussion drilling, earthwork drilling, etc., can solve the problems of low drilling efficiency, long drilling cycle, and short life of drill bits, and achieve significant economic benefits, prolong service life, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

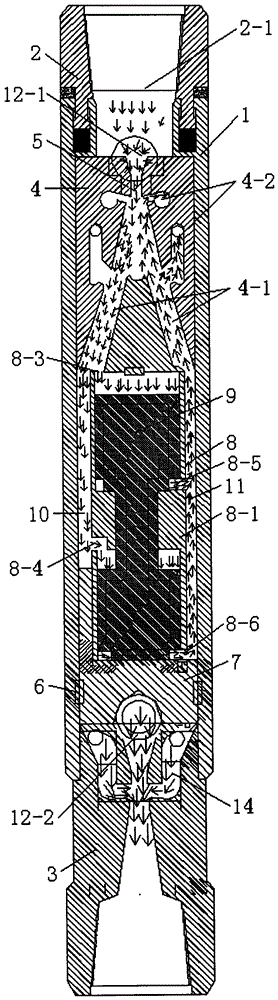

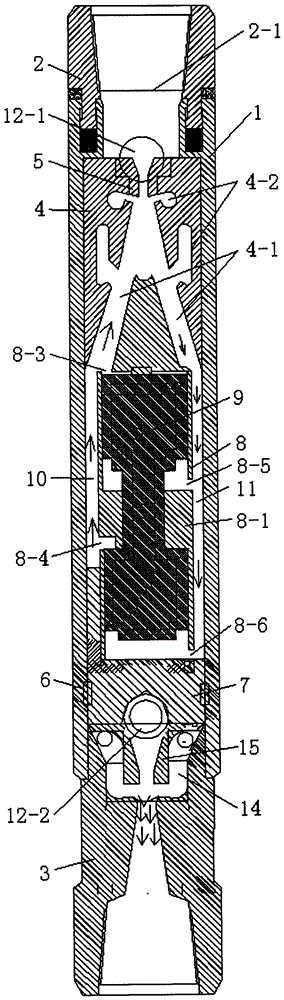

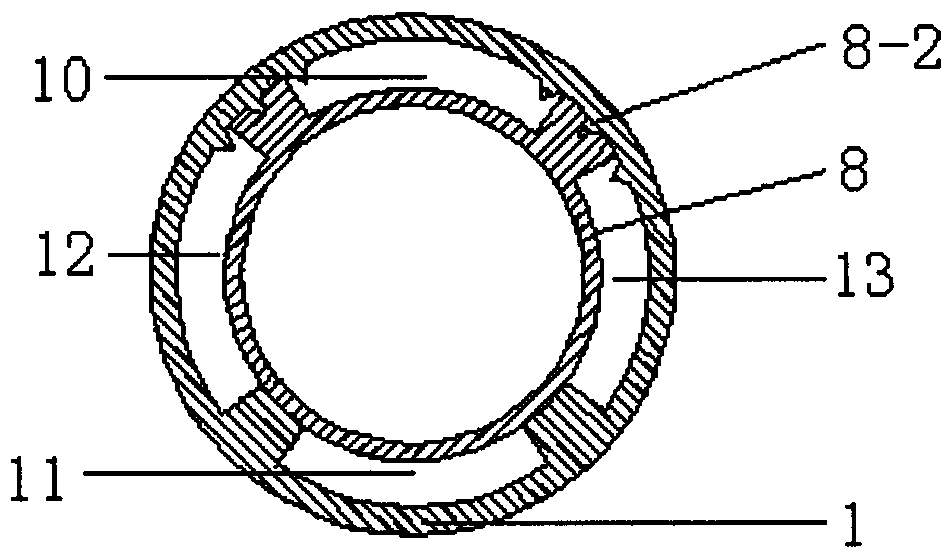

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

[0038] like Figure 1-2 As shown, a high-frequency drilling hammer provided by the present invention includes a pup housing 1, the upper end and the lower end of the pup housing 1 are respectively sealed and connected to an upper joint 2 and a lower joint 3, and the pup joint located at the lower part of the upper joint 2 A jet element 4 is interference-fitted in the shell 1, and the center of the top of the jet element 4 is provided with a jet element inlet nozzle 5 that communicates with the drilling fluid main inflow channel 2-1 at the upper joint 2 and the two output channels 4-1 of the jet element 4 . An anvil 7 is sealed and fastened in the sub joint housing 1 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com