A fracturing ship operating system

An operating system and fracturing technology, which is applied to special-purpose vessels, wellbore/well components, and production fluids, etc., can solve the problems of inability to carry out large-scale offshore oil and gas stimulation operations, and achieve the goal of solving large-scale offshore oil and gas stimulation operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

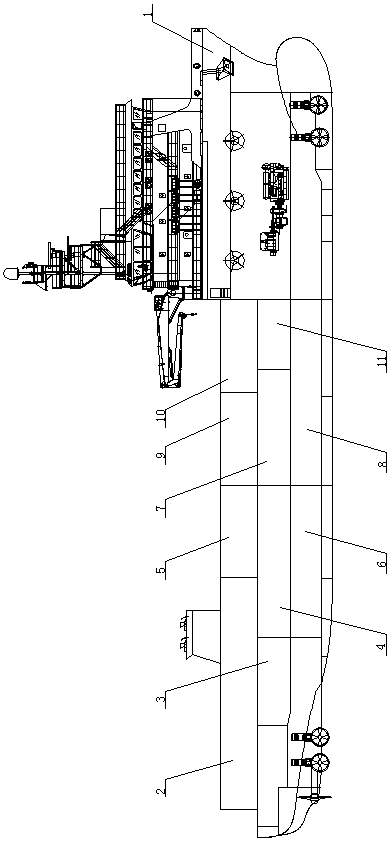

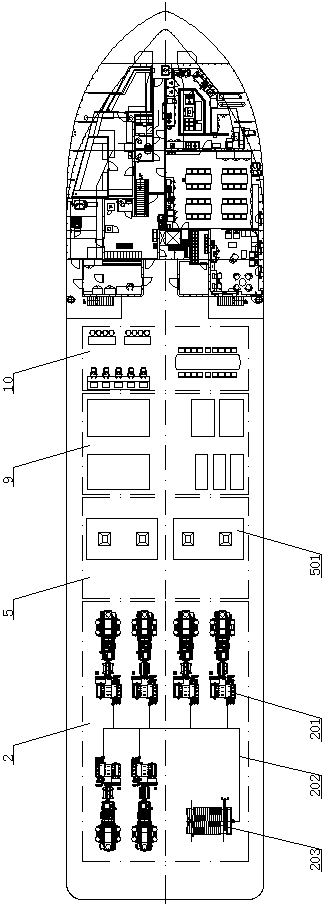

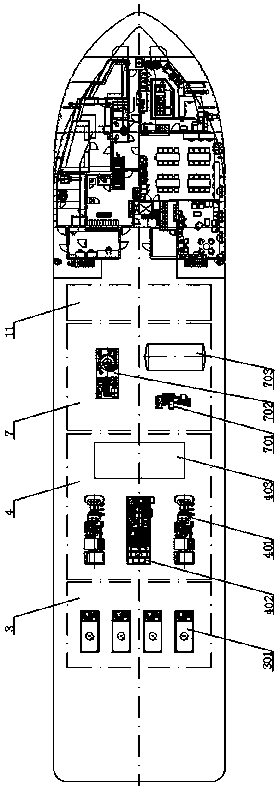

[0022] Attached below Figure 1-4 Specific embodiments of the present invention will be further described.

[0023] Such as figure 1 As shown, a fracturing ship operation system includes a high-pressure pumping area 2, a fracturing fluid mixing area 4, an acid mixing area 7, a proppant storage area 5, an acid storage area 6, a clean water storage area 8, Liquid additive area 3, bulk material storage area 9, fracturing control room 10 and quality laboratory 11, high-pressure pumping area 2 is located on the first deck of the fracturing ship near the stern, and proppant storage area 5 is located on the first deck of the fracturing ship near the stern. High-pressure pumping area, bulk material storage area 9 is located on the upper deck of the fracturing ship close to the proppant storage area, the fracturing control room 10 is located on the upper deck of the fracturing ship near the bow, and the liquid additive area 3 is located on the lower deck of the fracturing ship The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com