Low hydraulic head hydropower coagulation process method

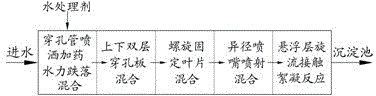

A process method, low head technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sedimentation tank, feeding/discharging device of sedimentation tank, etc. The problems of low effective utilization rate and insufficient mixing intensity have achieved the effect of ensuring consistency, good quadruple mixing effect, and significant energy saving and consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

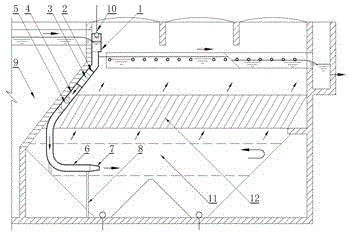

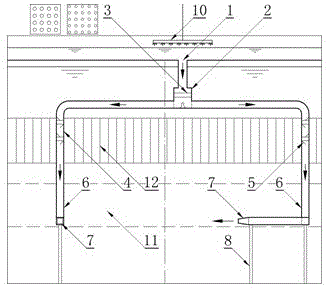

[0032] The present invention will be further described below by taking the accompanying drawings and embodiments as examples.

[0033] from figure 2 , image 3 with Figure 4 It can be seen from the figure that the L-type hydraulic mixing spinner of the main equipment used in the present invention is mainly composed of a water inlet 1, a water distribution tank 2, a double-layer perforated plate 3 in the tank, a wall-attached inclined tube 4, a spiral fixed blade 5, and an L-shaped curved tube. 6. The different-diameter nozzle 7 and the supporting member 8 are composed. In this L-shaped hydraulic mixing spinner, the upper and lower orifices of the double-layer perforated plate 3 in the water distribution tank 2 are staggered; the wall-attached inclined tube 4 is equipped with a second-stage spiral fixed blade 5; two L-shaped elbows 6 are arranged asymmetrically ; The different-diameter nozzle 7 at the end of the L-shaped elbow 6 is horizontal; the outlets of the two nozzle...

Embodiment 2

[0042] The sewage treatment capacity of a sewage treatment plant is 12,000 m 3 / d, there are 2 towers of 6000m each 3 / d's V-type air-lift integrated sewage treatment tank, adopts the low-head hydraulic coagulation process method of the present invention to carry out dosing, mixing and flocculation treatment of the clarified liquid in the clarification area of the integrated tank, and a total of 2 sets of L-type hydraulic mixing For the spinner, the caliber specification of the L-shaped elbow 6 is 300×300mm, the design flow velocity of the square pipe is 0.77m / s, the nozzle caliber specification of the different-diameter nozzle 7 is 240×240mm, and the nozzle design flow velocity is 1.21m / s, Good coagulation effect and final effect of sewage treatment are obtained. The water quality is shown in the table below.

[0043] Sewage treatment plant design inlet and outlet water quality table

[0044] project COD BOD 5 SS TN NH 3 -N TP Influent water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com