Synchronous generator for integrated rotary-magnetic external rotor oil press

A technology of synchronous generator and external rotor, which is applied to synchronous motors with stationary armatures and rotating magnets, etc., which can solve the problems of large energy waste, large volume, and low efficiency, and achieve improved efficiency, small volume, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

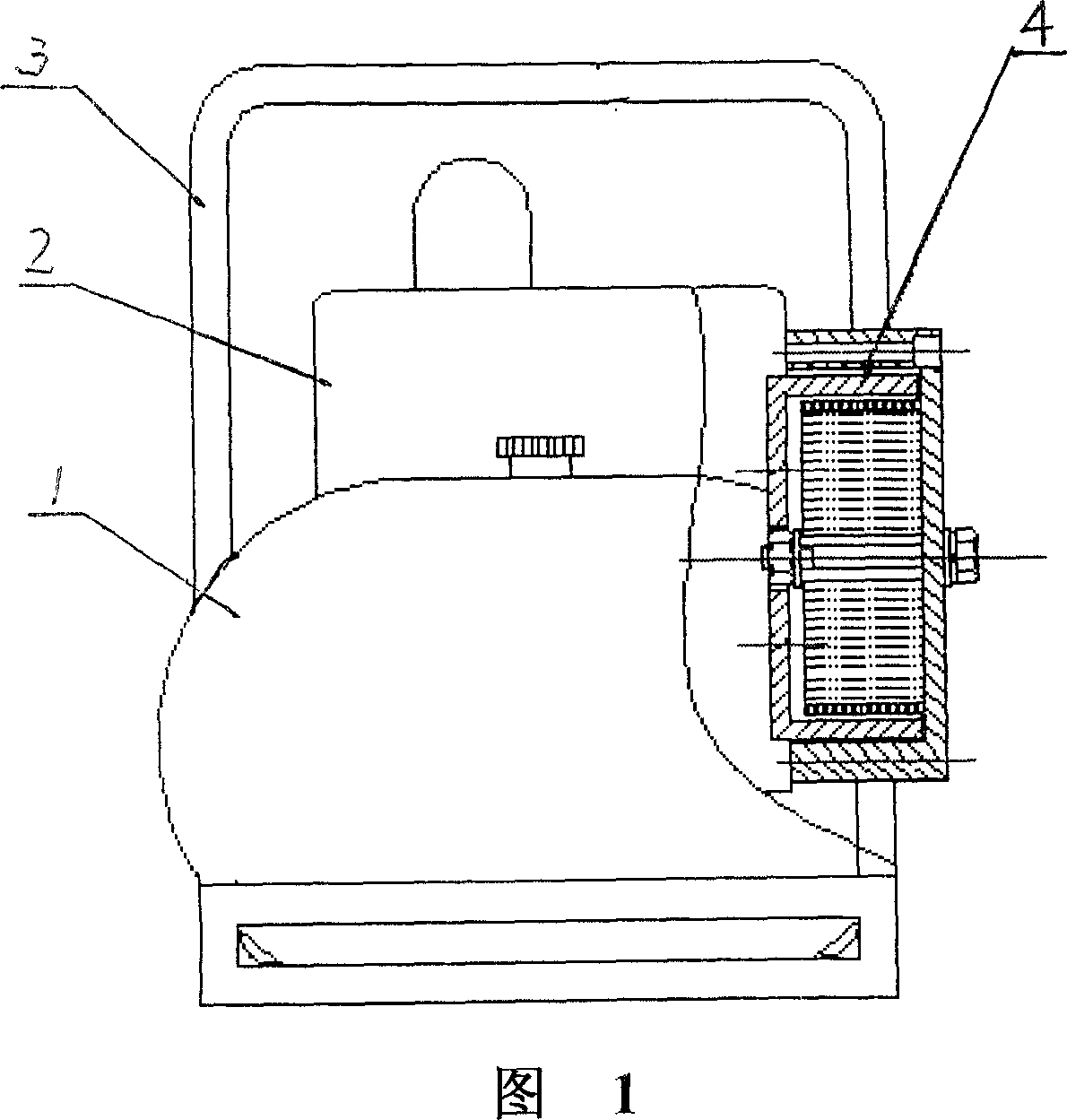

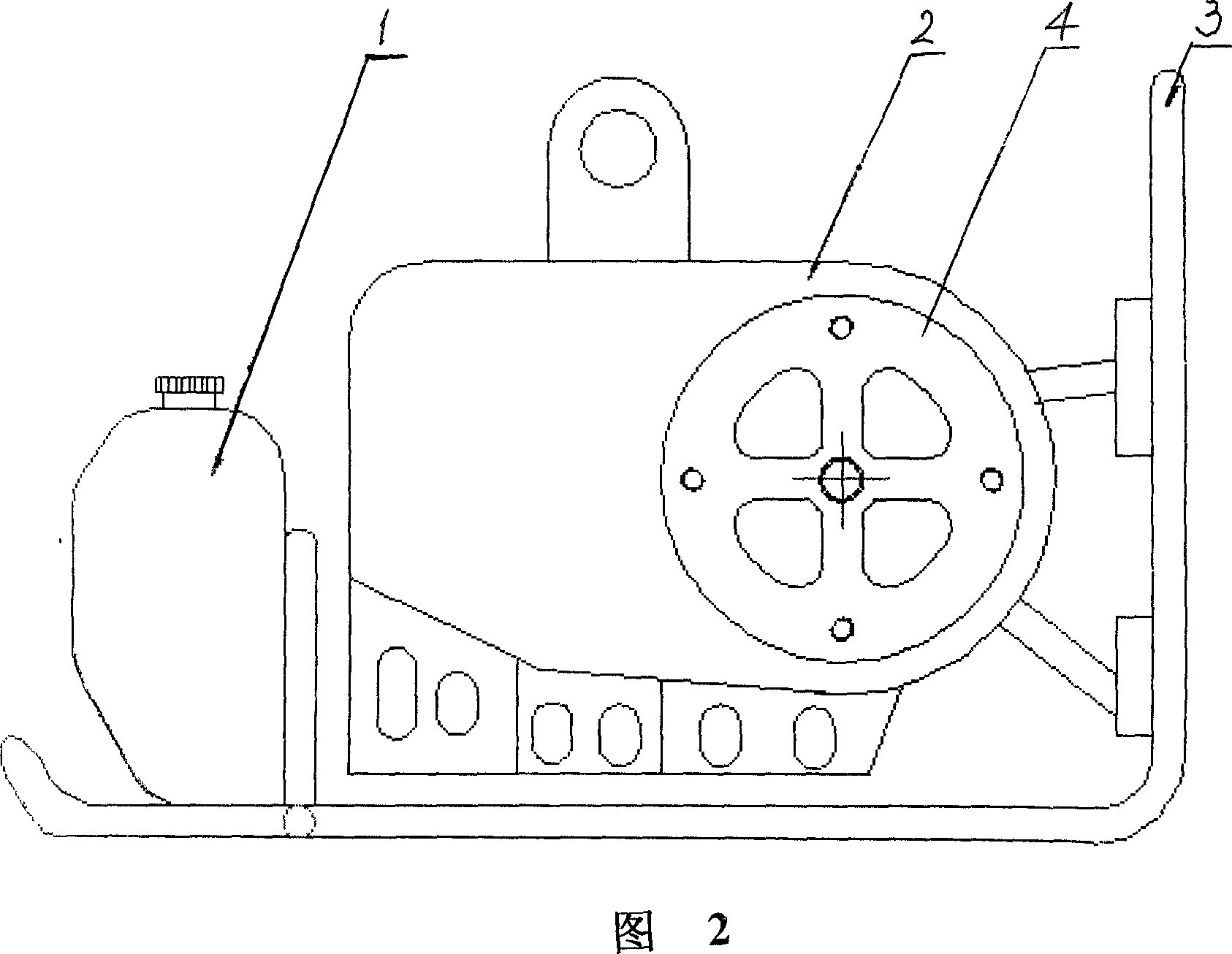

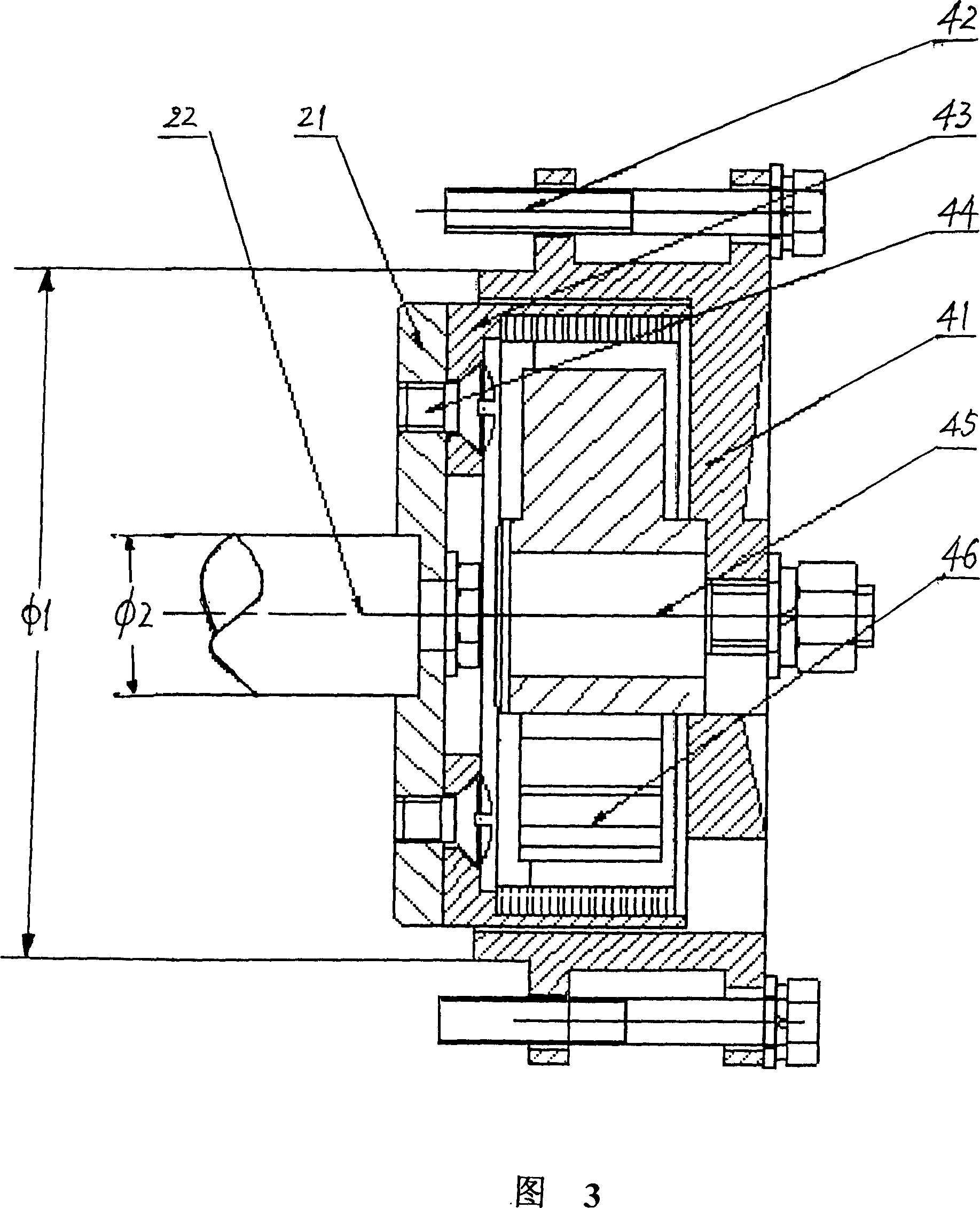

[0014] Referring to the accompanying drawings, the integrated rotating magnet outer rotor synchronous generator of the present invention is composed of a fuel tank 1, an oil generator 2, a support 3 and a rotating magnetic outer rotor synchronous generator 4, and the fuel tank 1 and the gasoline engine Or the oil machine 2 composed of a diesel engine is installed on the support 3, the magnetic outer rotor 43 of the generator 4 is fixed on the rotating shaft of the oil machine, and the stator 46 of the generator is concentrically arranged in the magnetic outer rotor 43 and passed through the motor. The stator fixing sleeve 41 is fixedly connected with the housing of the oil machine, and there is an appropriate gap between the stator 46 and the magnetic outer rotor 43, so that the generator 4 is generally fixed on the rotating shaft and the housing of the oil machine 2 like a small part, reducing the Reduced volume and weight (the oil engine generator looks like a single oil engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com