Clamp ring structure

A snap ring and fastening bolt technology, which is applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of time-consuming and labor-intensive tying process, pulling out holes, and easy loosening of tying knots. The operation, the effect is ideal, and the effect of binding is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

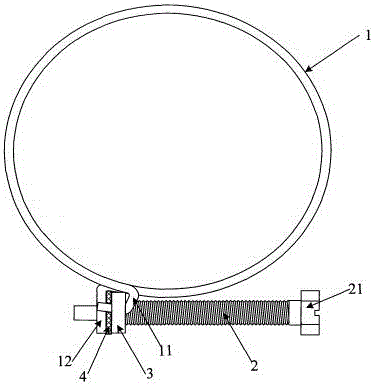

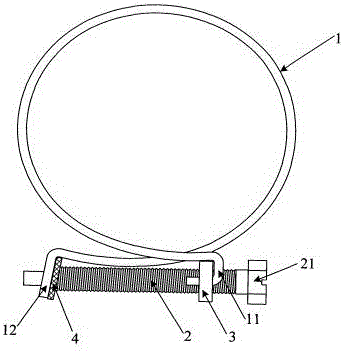

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

[0011] As shown in Figure 1, the fastening plate 3 is connected to the fastening bolt 2 by a screw. The threaded connection described here means that the fastening plate 3 is embedded with a second thread that matches the first thread on the fastening bolt 2, so that the fastening plate 3 relies on the first thread on it. The two threads can move helically on the fastening bolt 2 along the first thread. Washer 4 is also attached to fastening bolt 2. However, the fastening plate 3 is located between the washer 4 and the head 21 of the fastening bolt 2 . The hoop 1 is an open ring structure surrounded by elastic steel wire material. The hoop 1 includes two connecting ends: a first connecting end 11 and a second connecting end 12. The first connection end 11 and the second connection end 12 are connected to the fastening plate 3 and the gasket 4 respectively after interse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com