One-way cyclic starting structure of novel oscillation type heat conduction device

A one-way circulation, oscillating technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as limited starting force, difficulty in achieving one-way circulation of working fluid, and inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

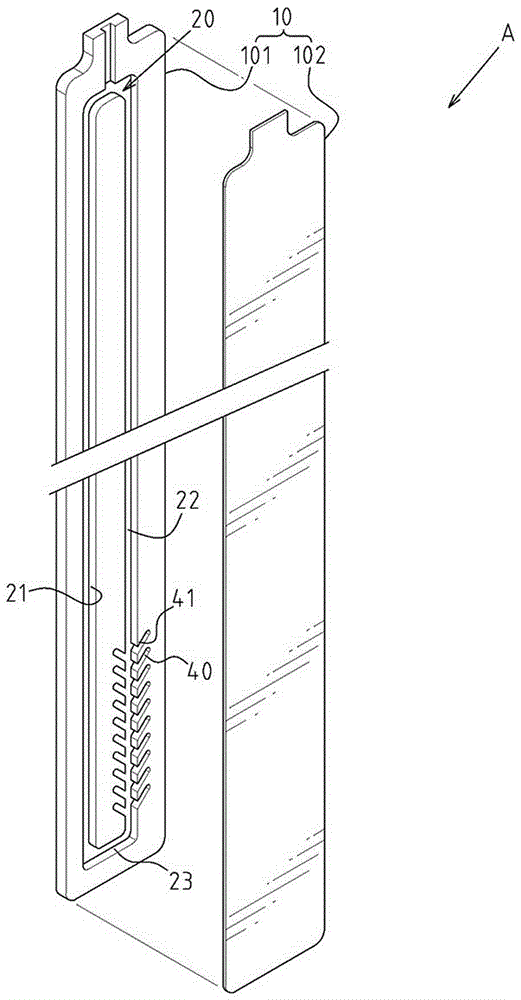

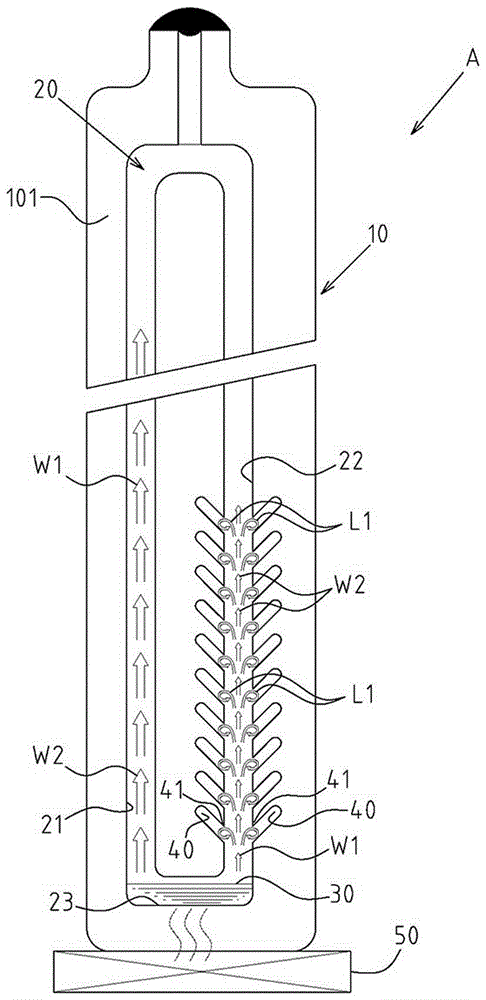

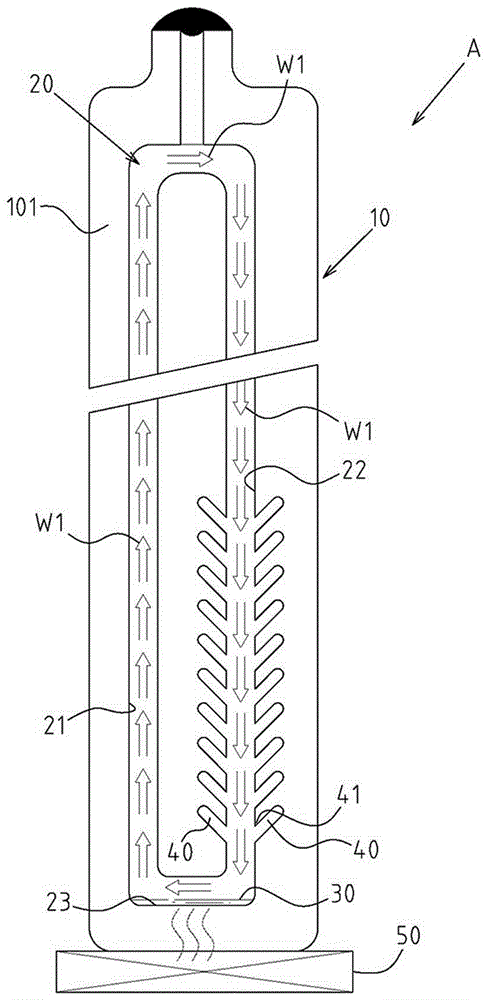

[0024] Example: see Figure 1~4 Shown is a preferred embodiment of the one-way cycle start-up structure of the novel oscillating heat conduction device of the present invention, but these embodiments are for illustration purposes only, and are not limited by this structure in patent application.

[0025] The oscillating heat conduction device A includes a casing 10 and a loop-type flow channel 20 inside the casing 10. The loop-type flow channel 20 includes a heated section 23 and a first side guide section 21. And a second side guide section 22, and a working fluid 30 is placed in the loop-type flow channel 20, and the working fluid 30 in the heated section 23 evaporates to form a vapor pressure to push the working fluid 30 to flow; and wherein, the first At least one side of the two-side guide section 22 is provided with at least one fork-shaped spoiler 40 protruding sideways in the form of a blind hole, between the fork-shaped spoiler 40 and the second side guide section 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com