Cassette structure capable of detecting substrate integrity and method for detecting substrate integrity

An integrity and substrate technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve problems that affect production efficiency, cannot detect substrate cracks, consume a lot of time, and manually clean debris to avoid production Effects of threats to efficiency and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

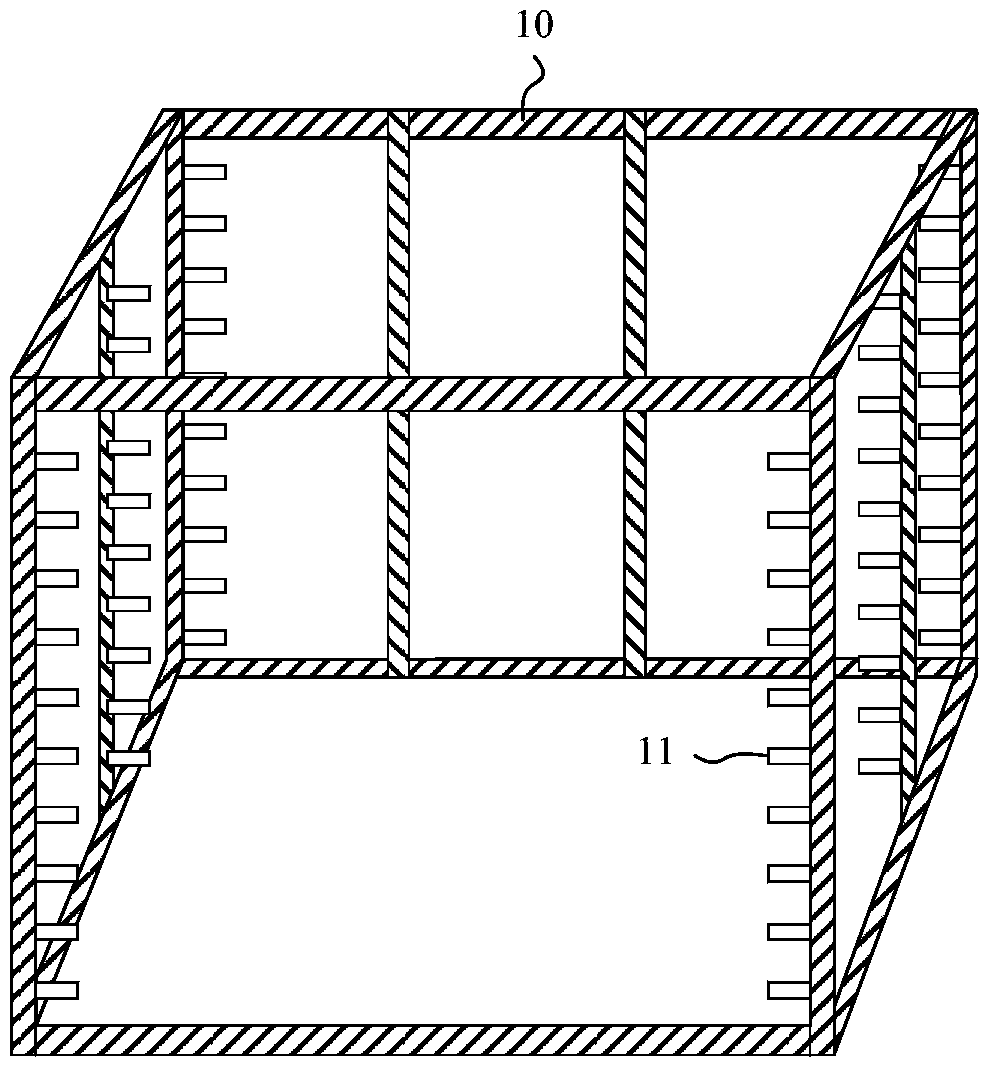

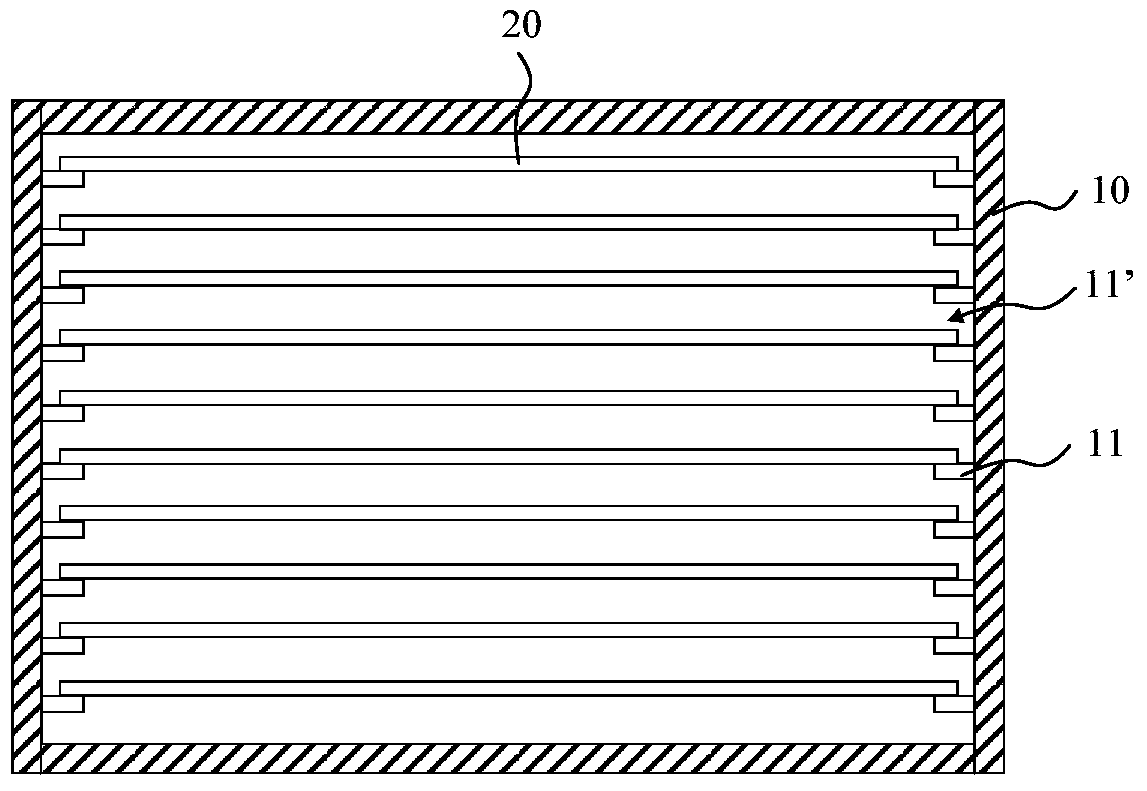

Embodiment 1

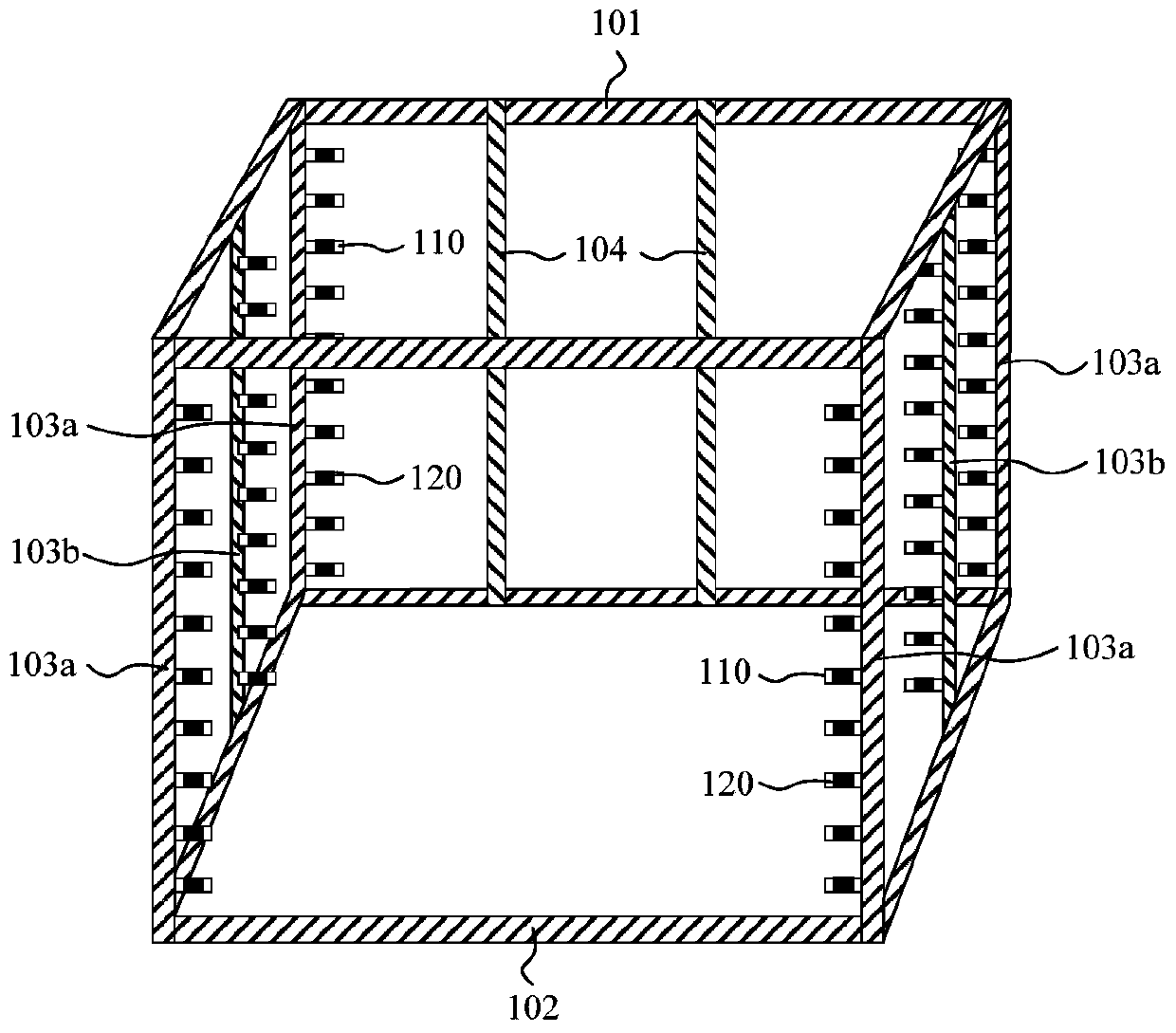

[0035] In this embodiment, the detection unit is a pressure detection unit as an example for detailed description. image 3 A schematic diagram of the cassette structure provided in this embodiment, Figure 4 for image 3 The card gate structure shown is the front view of the carrier substrate. Such as image 3 with Figure 4 As shown, the cassette structure includes an outer frame, a supporting member 110, a pressure detection unit 120, and a signal processing unit (not shown in the figure). The supporting members 110 are arranged at intervals on two opposite sides inside the outer frame, and the supporting members 110 are arranged in layers to define a plurality of accommodating spaces 110', thereby supporting the substrate 200. The pressure detecting unit 120 is disposed on the surface of the supporting member 110 carrying the substrate, and generates a pressure sensing signal indicating the integrity of the substrate. The signal processing unit is connected to the pressure ...

Embodiment 2

[0049] In this embodiment, the detection unit is an optical detection unit as an example for detailed description. Picture 12 A schematic diagram of the cassette structure provided in this embodiment, Figure 13 for Picture 12 The card gate structure shown is the front view of the carrier substrate. Such as Picture 12 with Figure 13 As shown, the cassette structure includes an outer frame, a supporting member 110, an optical detection unit 130, and a signal processing unit (not shown in the figure). The supporting members 110 are arranged at intervals on two opposite sides inside the outer frame, and the supporting members 110 are arranged in layers to define a plurality of accommodating spaces 110', so as to accommodate and support the substrate 200. The optical detection unit 130 is disposed on the supporting member 110 and located on two opposite sides of the accommodating space 110' to generate a light intensity sensing signal indicating the integrity of the substrate. ...

Embodiment 3

[0059] In this embodiment, the detection unit includes both a pressure detection unit and an optical detection unit as an example for detailed description. Figure 14 It is a front view of the cassette carrier substrate provided by this embodiment. Such as Figure 14 As shown, the cassette structure includes an outer frame, a supporting member 110, a pressure detection unit 120, an optical detection unit 130, and a signal processing unit (not shown in the figure). The pressure detecting unit 120 is disposed on the surface of the supporting member 110 carrying the substrate, and generates a pressure sensing signal indicating the integrity of the substrate. The signal processing unit is connected to the pressure detection unit 120 to receive the pressure sensing signal and process the pressure sensing signal. The optical detection unit 130 is arranged on the supporting member 110 and located on two opposite surfaces of the accommodating space 110', and generates a light intensity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com