Array substrate, display panel and array substrate preparation method

A technology of array substrate and display area, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of reflection, light leakage of metal leads in the surrounding lead area, and high production cost of narrow frame products, and achieve enhanced shading effect , Avoid reflections, reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

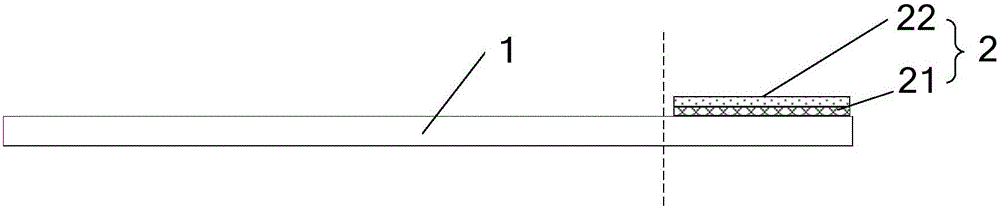

[0045] This embodiment provides an array substrate, such as figure 1 As shown, it includes a base 1. The base 1 includes a display area and a lead area. The display area is an area for forming thin film transistors, pixel electrodes, and common electrodes, including the thin film transistor area and the electrode area. The wire area is an area used to form metal wires connected to signal lines of thin film transistors, pixel electrodes, and common electrodes. The array substrate further includes a shielding layer 2, which is located in the wiring area of the substrate 1 and is used to shield metal wirings (not shown in the figure) in the wiring area. The shielding layer 2 includes an anti-reflection film layer 21 , and the anti-reflection film layer 21 is formed on the substrate 1 .

[0046] Further, the shielding layer 2 may further include a metal film layer 22 , and the metal film layer 22 is formed on the anti-reflection film layer 21 . That is to say, the anti-reflect...

Embodiment 2

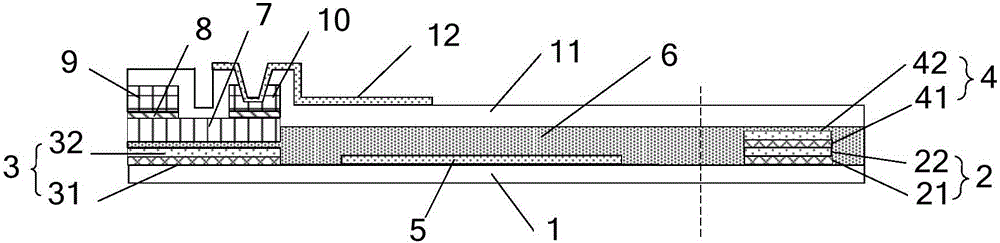

[0052] This embodiment provides an array substrate, such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that it also includes a first anti-reflection layer 3 formed on the substrate 1 in the display area. The reflectivity of metal film layers such as common electrodes and common electrodes to ambient light. The structure of the array substrate in embodiment 2 in the wiring area is the same as that in the array substrate in embodiment 1 in the wiring area, and will not be repeated here.

[0053]Specifically, the first anti-reflection layer 3 includes an anti-reflection film layer 31 and a metal film layer 32 , and the anti-reflection film layer 31 is located between the metal film layer 32 and the substrate 1 .

[0054] Further, such as figure 2 As shown, the array substrate may also include a second anti-reflection layer 4 formed on the shielding layer 2, the second anti-reflection layer 4 includes an anti-reflection film layer 41 and a me...

Embodiment 3

[0065] This embodiment provides a display panel. The display panel includes the aforementioned array substrate, and the structure of the array substrate will not be repeated here.

[0066] By forming a shielding layer in the lead region of the substrate, the shielding layer is used to shield the metal leads in the lead region, eliminating the exposed state of the metal wires in the lead region around the array substrate, avoiding the reflection of the metal leads, and being more beautiful; the anti-reflection film in the shielding layer The layer is located between the metal film layer and the substrate, which can reduce the reflectivity of external light, thereby enhancing the shading effect; in addition, the solution of the present invention can form a shading layer with the help of existing equipment in the array substrate preparation process, without additional ink coating Overlay equipment, reduce equipment investment, thereby reducing production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com