Anti-collision electrical cabinet based on integral framework

An integral frame and electrical cabinet technology, applied in the field of electrical cabinets, can solve the problems of increasing wall thickness, increasing wall thickness and reinforcing ribs, failing to meet anti-collision requirements, and achieving the effect of avoiding mutual collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

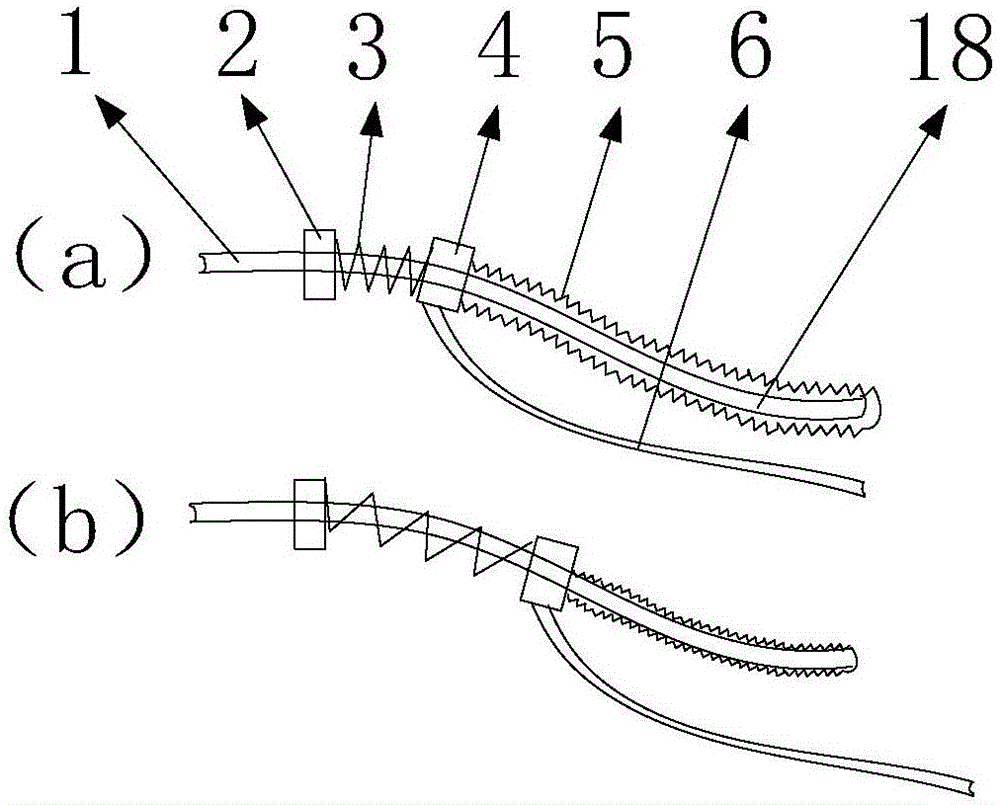

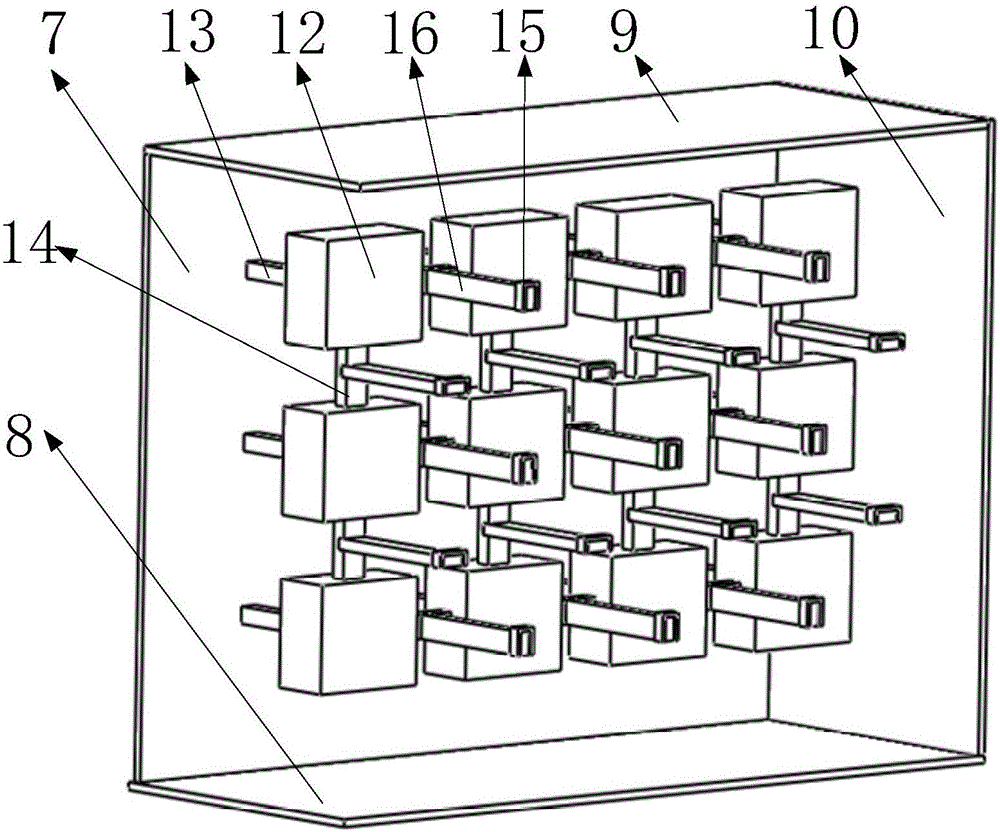

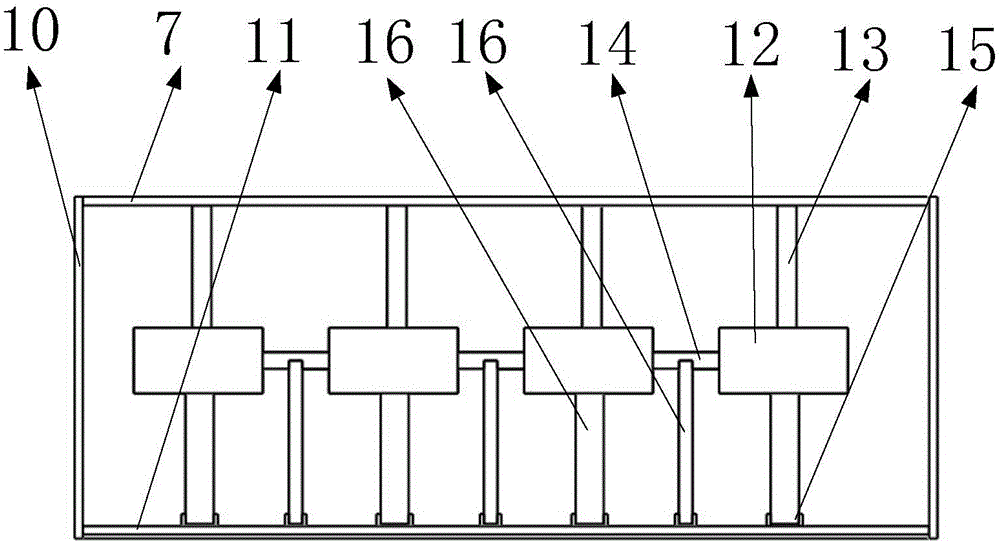

[0022] Such as figure 2 , 3 As shown, it includes rear plate, bottom plate, top plate, side plate, front plate, component mounting shell, rear support, connection support, U-shaped fixed block, front support, fracture groove, telescopic wire mechanism, among which figure 2 As shown, the front board, two side boards, and the rear board are installed on the bottom board with a rectangular cross-section, and the top board is installed on the top of the front board, the rear board and the two side boards; Figure 7 As shown, the 12 rear supports are divided into three groups and the three groups are installed side by side and equidistant on the rear plate, as shown in figure 2 , 3 As shown, a component mounting shell is installed on the top of each rear support, such as Figure 4 As shown, the adjacent component mounting shells are connected to each other through connecting supports, and each connecting support has a fracture groove in the middle, as shown in image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com