Suction channel for an extractor device for conveying cut waste strips of a film web

A technology of suction equipment and channels, which is used in the transportation of bulk materials, conveyors, applications, etc., can solve the problems of the application of edge strips with no clear composition, the inability to provide, and the impossibility of considering material differences, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

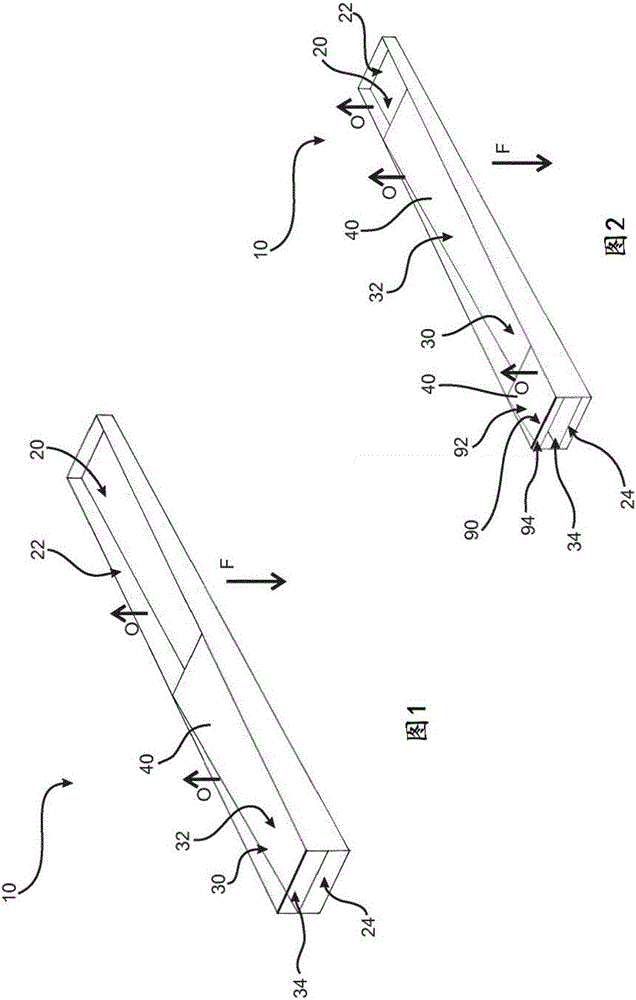

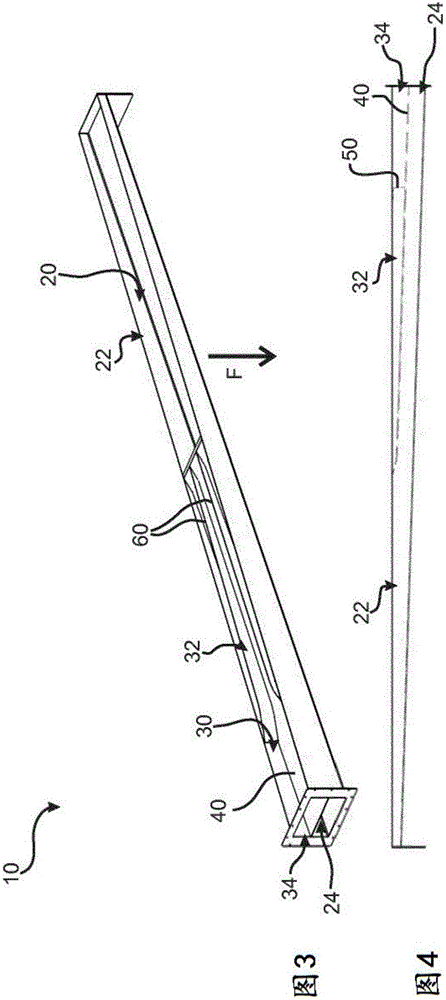

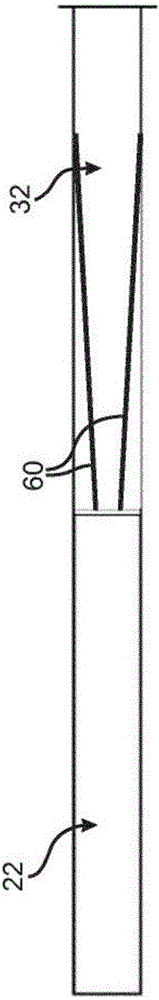

[0038] exist figure 1 An embodiment of the suction channel 10 according to the invention is schematically shown in . It can be clearly seen here that the common partition wall 40 separates the two individual channel sections 20 and 30 from one another over the entire width of the suction channel 10 . Each of the two channel sections 20 and 30 has its own channel section inlet 22 and 32 . One or more trim strips 210 of the film web 200 can be sucked in through the completely open channel section inlets 22 and 32 , which here are formed with an upward opening direction O. FIG. The two channel inlets 22 and 32 are spaced apart from one another transversely to the conveying direction F of the film web 200 shown, so that differently positioned and cut trim strips 210 are sucked in depending on their position and are drawn individually in the corresponding channel section 20 and 30 are booted. At the lower left end, the two channel sections 20 and 30 lead to the corresponding cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com