A winding type drawing top heading pipe bending machine

A kind of upsetting pipe bending machine, winding technology, applied in the field of winding type drawing top upsetting pipe bending machine, to achieve the effect of stable transmission, improved efficiency and flexible action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

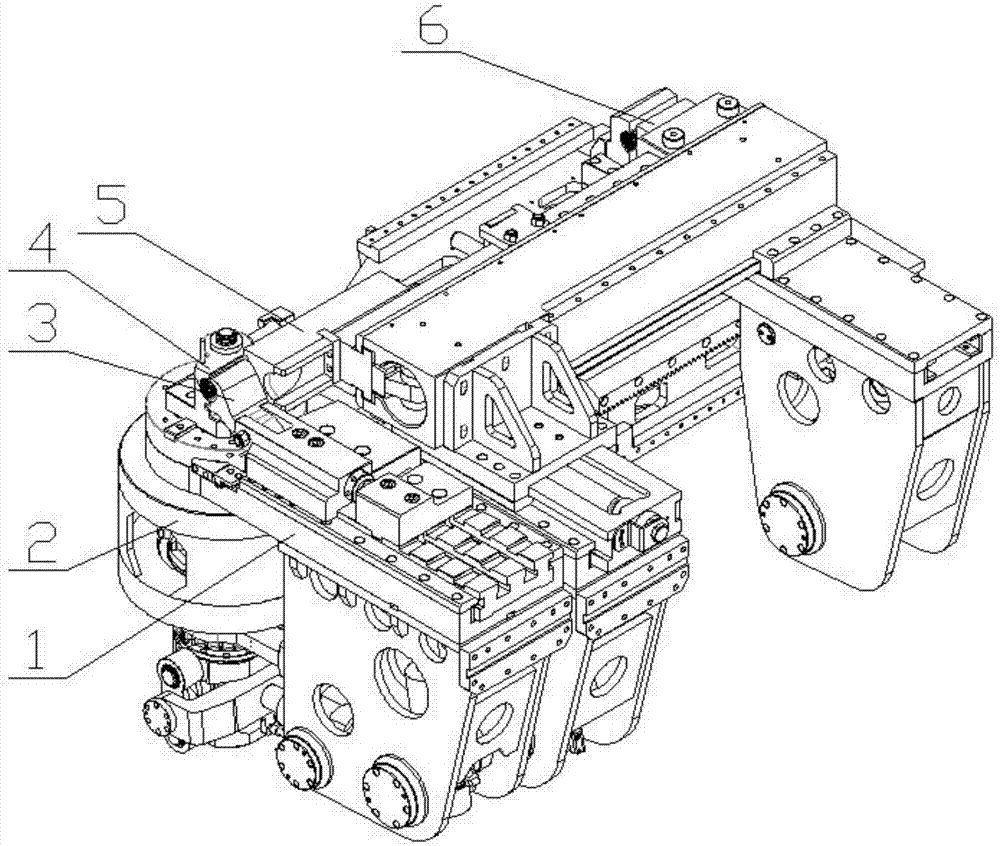

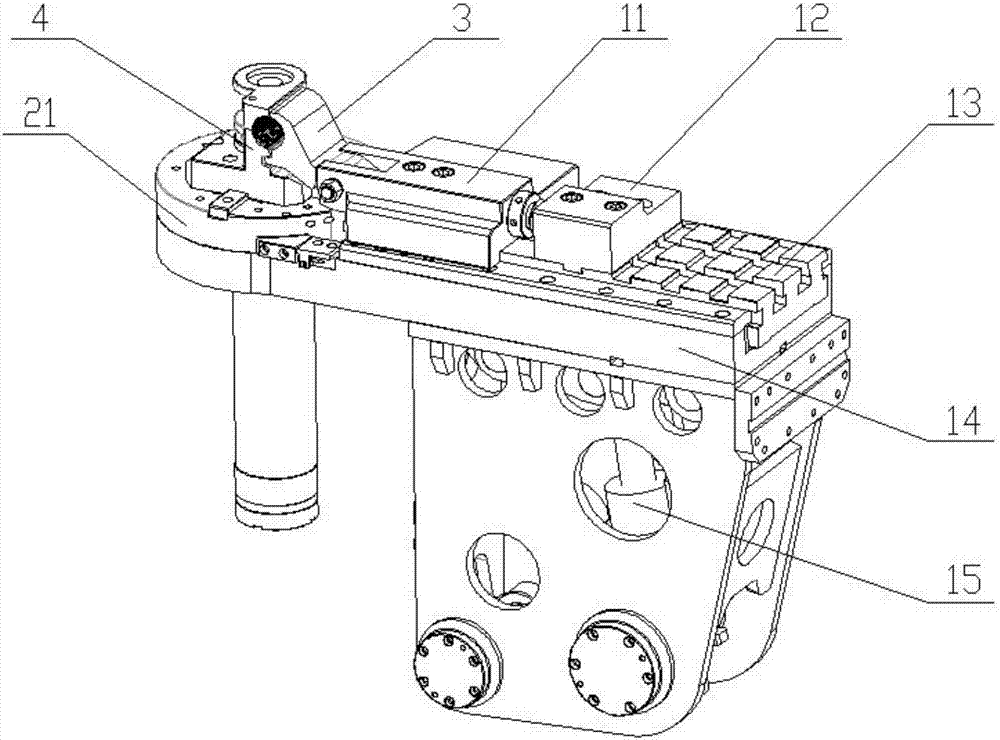

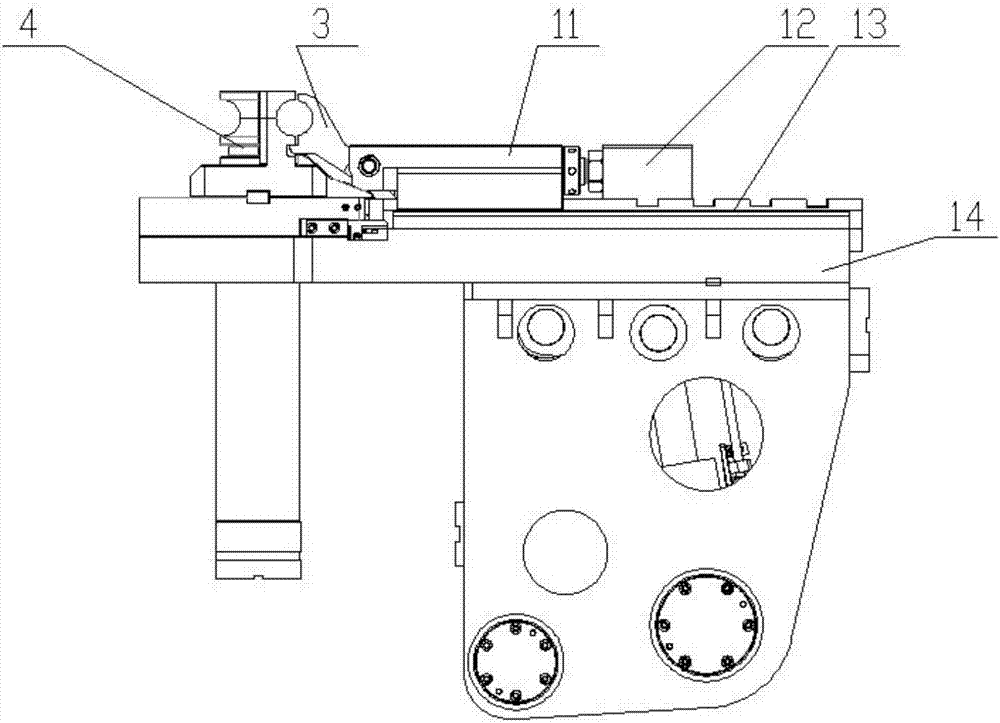

[0047] Such as figure 1 As shown, a winding type drawing top heading pipe bender includes a clamping device 1, a main mold reset device 2, a clamping mold 3, a main mold 4, a pressing rail mold 5, and a top heading mechanism 6, such as Figure 13 As shown, the master mold resetting device 2 includes a master mold holder 21, a master mold support 22 and a master mold holder gear 24; as figure 2 , image 3 and Figure 4 As shown, the clamping device 1 includes a clamping mold base 11, a slider 13, a slider base 14 and a slider drive 15;

[0048] The main mold holder 21 is rotatably arranged on the main mold support 22, specifically as Figure 14 As shown, the main mold support 22 is a hollow structure, the upper end of the main mold 21 is connected with the upper end surface bearing of the main mold support 22, and the lower end passes through the main mold support 22 and is fixedly connected with the main mold holder gear 24; Main mold support 22 is connected by bearing, a...

Embodiment 2

[0060] A winding type drawing and upsetting pipe bending machine, which is basically the same as that of Embodiment 1, except that a track is provided on the upper surface of the slider 13 close to the main mold 4, and a T-shaped groove is provided on the other side; Figure 5 or Figure 11 As shown, the mold clamping seat 11 is arranged on the track, and is fixed by a set bolt 116, and the clamping mold positioning seat 12 is arranged on the T-shaped slot, and is fixed by a set bolt 121; Figure 5 As shown, the clamping mold base 11 is provided with a clamping mold fixing groove 111 at one end close to the main mold 4, and the clamping mold 3 is rotatably arranged in the clamping mold fixing groove 111 through a pin shaft, and the other end of the clamping mold base 11 is provided with a clamping mold fine-tuning Rod 112, clamping mold fine-tuning lever 112 one end is threadedly connected with the end face of clamping mold base 11, and the other end contacts with clamping mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com