A kind of adjusting device and method based on 3D printer

A technology of 3D printer and adjustment device, which is used in manufacturing auxiliary devices, 3D object support structures, additive manufacturing, etc., to achieve the effect of improving line width consistency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in further detail below with reference to the drawings and embodiments.

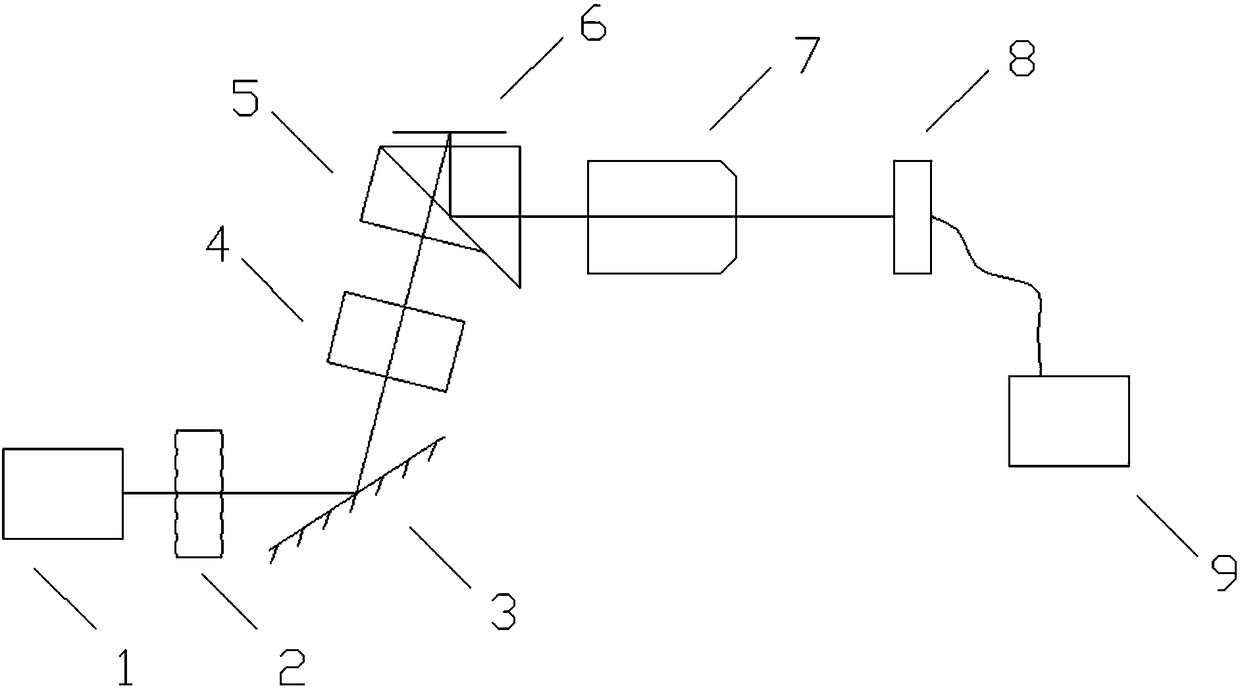

[0029] figure 1 A model diagram of an adjustment device based on a 3D printer provided for an embodiment of the present invention. Such as figure 1 As shown, the device includes: an illumination module, a projection module, and a power detection module; wherein, the illumination module includes a light source 1, a microlens array 2, an optical lens group 4, an RTIR prism 5, and a reflector 3; the projection module includes a programmable A pattern generator 6 and a projection lens 7; the power detection module includes a power probe 8 and a power display 9; the reflector 3 is obliquely arranged on the rear optical path of the light source 1 and the microlens array 2, and the reflective optical path of the reflector 3 is sequentially arranged on the optical path Lens group 4 , RTIR prism 5 and pattern generator 6 , projection lens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com