Threshing chamber concave plate of harvester

A threshing room and harvester technology, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of crop weed discharge, heavy screen surface load, and large thickness of partitions, so as to reduce cleaning load and damage. Small, damage-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

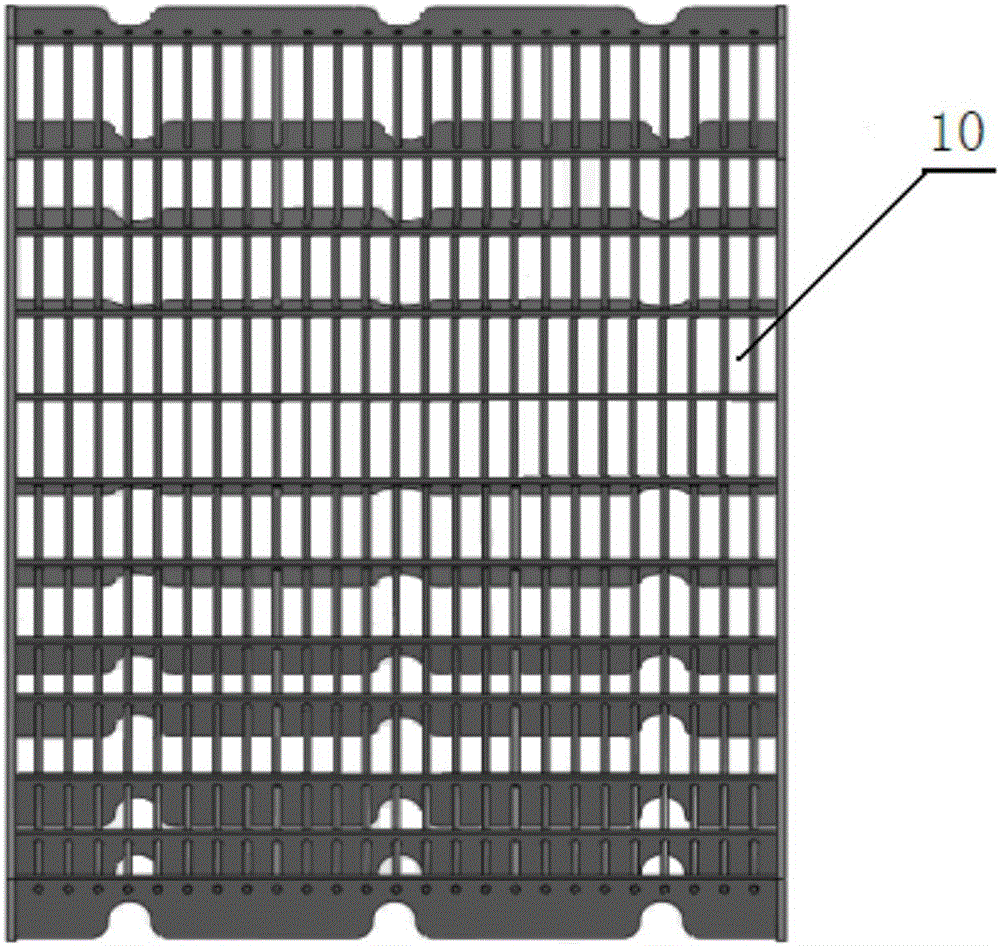

Image

Examples

Embodiment Construction

[0027] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

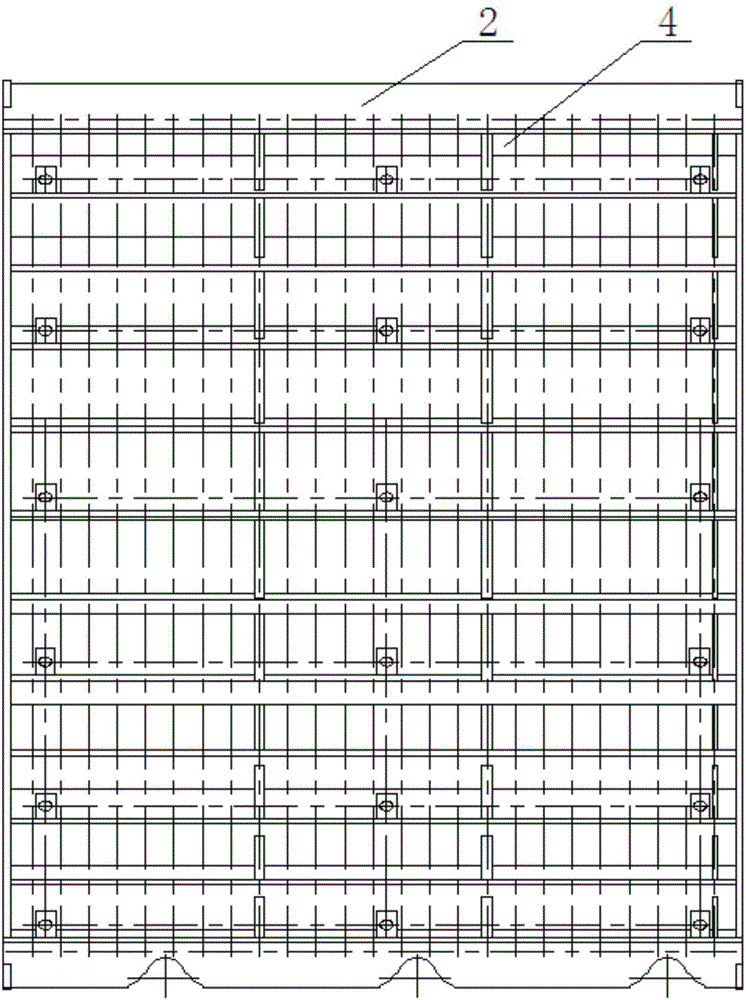

[0028] see image 3 , according to the present invention for the threshing chamber concave plate harvester, including: a support frame 2 and a mesh concave screen 4. The support frame 2 is fixedly arranged under the drum of the threshing chamber (not shown in the figure), and is used to fix the mesh concave plate sieve 4; the mesh concave plate sieve 4 is arranged on the support frame 2, and is used for filtering the grains after detaching and straw. The threshed grains are filtered through the mesh concave plate sieve and then fall into the cleaning chamber.

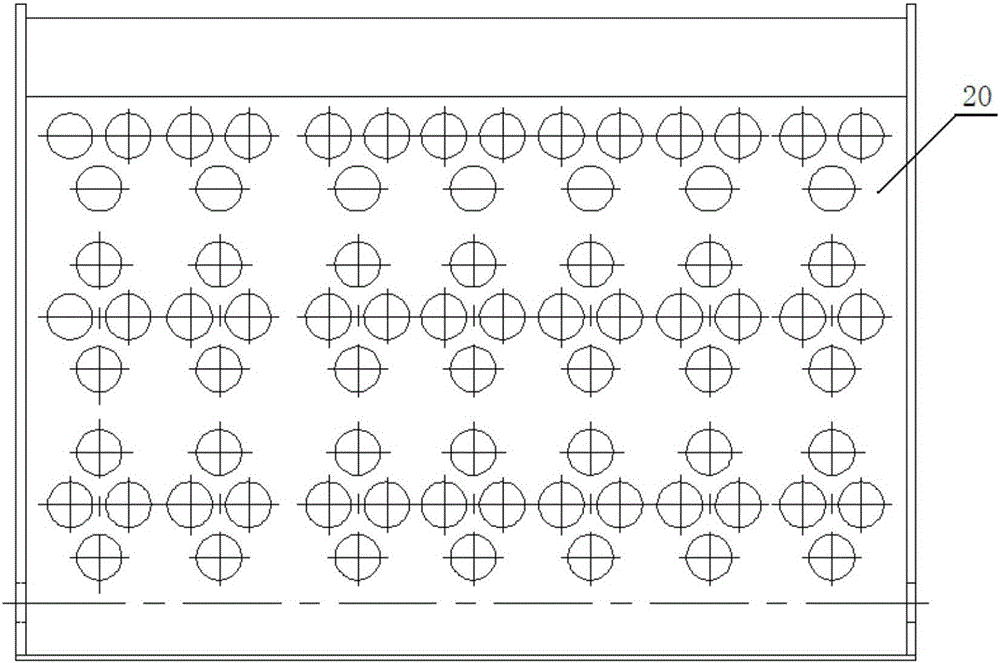

[0029] Mesh concave screen 4 is formed by lapping horizontal steel wire 5 and longitudinal steel wire 6, Figure 5 shows a front view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com