Novel milk bottle sterilizer

A technology for sterilizers and baby bottles, which is applied in disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of single function, disinfection is limited to the irradiated surface of objects, and only ultraviolet disinfection function, etc., and achieves convenient use and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention and specific implementation thereof are described in further detail:

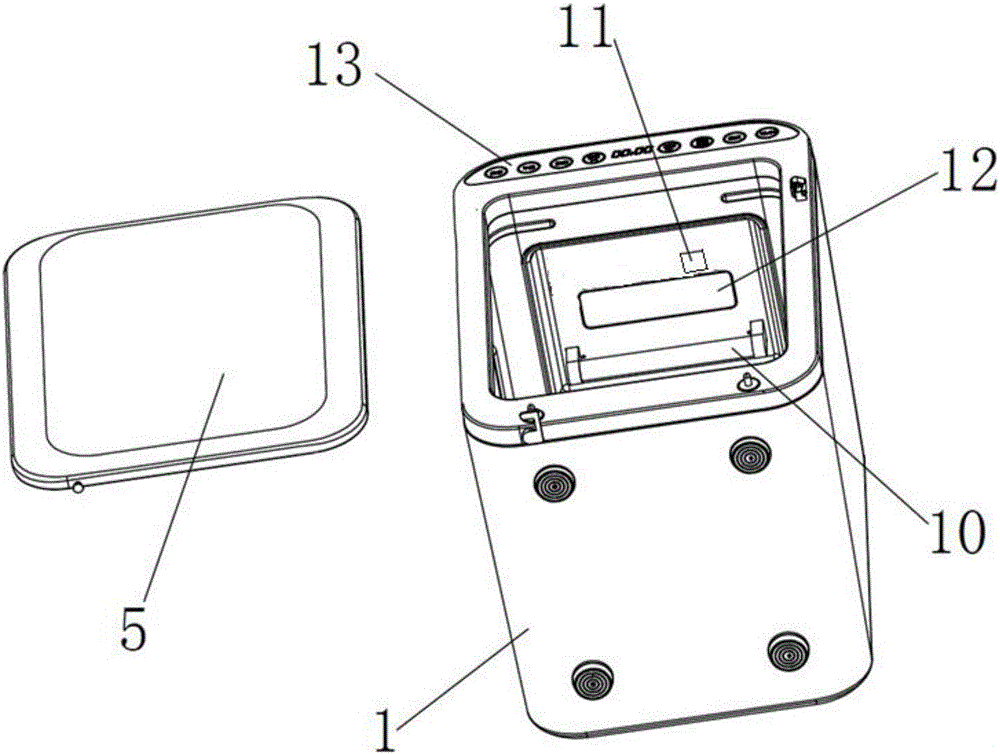

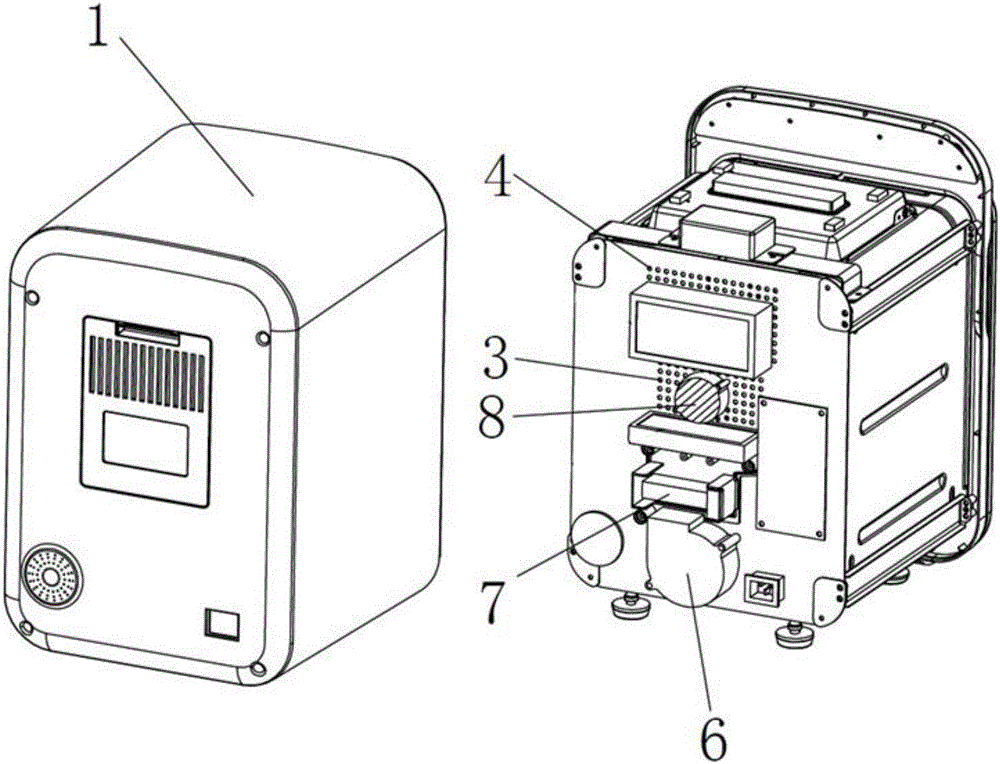

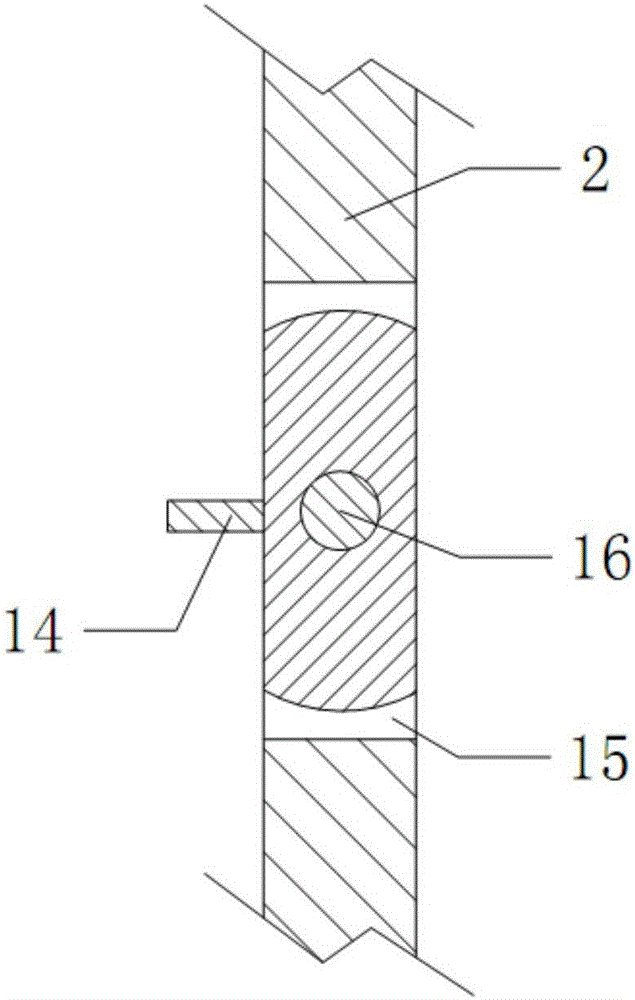

[0017] see Figure 1 to Figure 4 , the present invention includes a box body 1, the box body 1 is provided with a cavity 2, the cavity body 2 is provided with an air inlet hole 3 and an air outlet hole 4, and the box body 1 is hinged to connect the cavity body 2 a sealed box door 5, the box body 1 is provided with a first fan 6 for sending outside air into the box body 1, the air outlet of the first fan 6 is provided with a heating element 7, and the air inlet hole 3 is provided with The hot air heated by the heating element 7 is sent into the second fan 8 in the cavity 2, and the box 1 is provided with a controller 9 connected with the first fan 6, the heating element 7, and the second fan 8 respectively, Described controller 9 is connected with being arranged on the ultraviolet lamp 10 that is used for disinfection in cavity 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com