Double-shaft shredding machine

A double-shaft shredder and cutter shaft technology, applied in grain processing, etc., can solve the problems of blocked cutter shaft operation, insufficient cutting force of the cutter body, damaged bearings, etc., to achieve smooth operation of the cutter shaft, strong cutting force, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

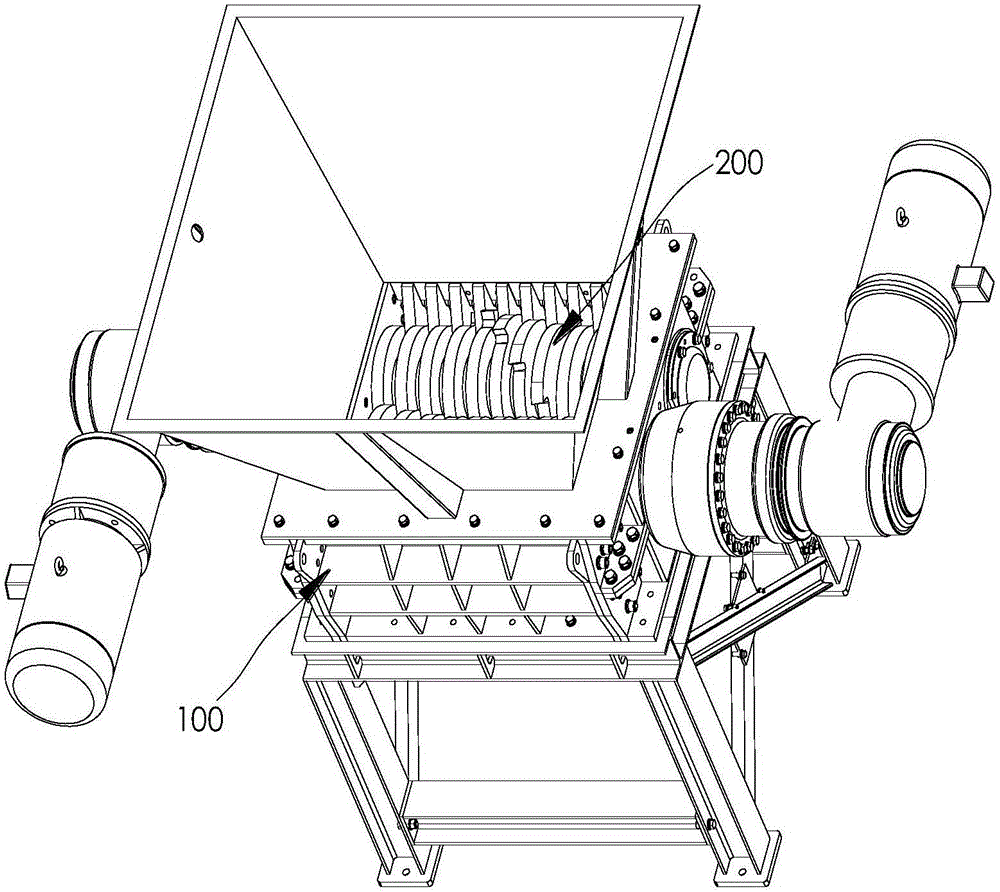

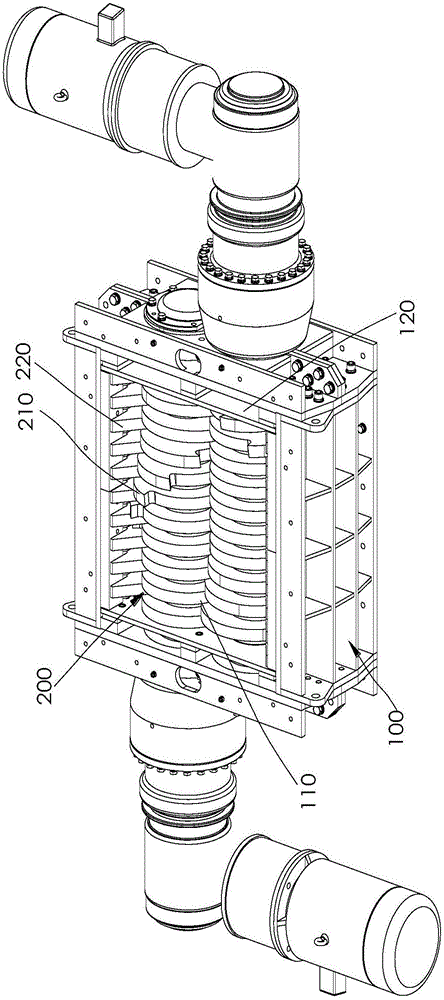

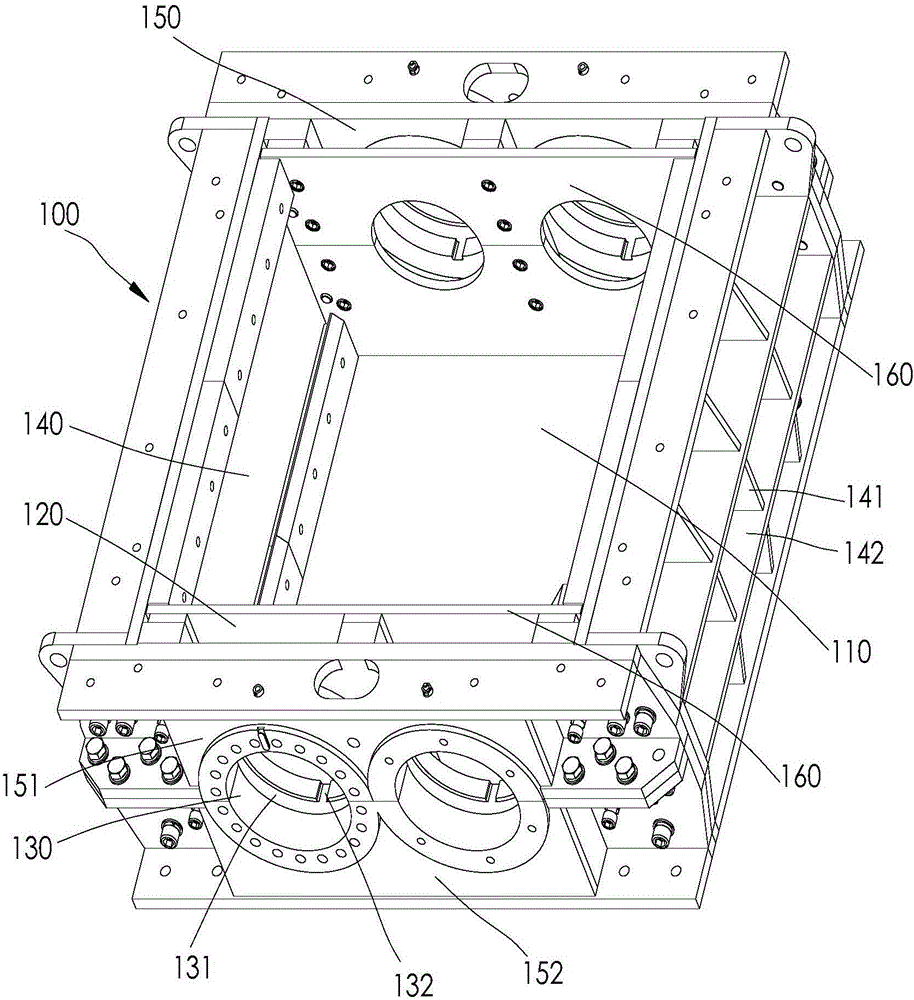

[0027] Such as Figure 1-9 The shown double-shaft shredder includes a box body 100 and a cutter 200; specifically, a crushing cavity 110 is formed inside the box body 100, and both ends of the crushing cavity 110 are provided with a mounting plate 150 and a partition 160, and the mounting plate 150 and the partition 160 are arranged at intervals, the mounting plate 150 is packaged on the outside of the partition 160 , and a first gap 120 is formed between the mounting plate 150 and the partition 160 , and the first gap 120 communicates with the crushing chamber 110 .

[0028] In addition, it includes two knife shafts 230, a cutting knife body 210, and a scraping knife body 220. The two ends of each knife shaft 230 respectively pass through the partition plate 160 in the crushing chamber 110, and are pivotally connected to the mounting plate 150 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com