Casting head removing machine

A technology for pouring risers and oil cylinders, which is applied in the field of iron cap pouring riser removal equipment, can solve the problems of difficult processing of large parts, high labor intensity, and harmfulness to the human body, and achieves the solution of hammering difficulties, labor intensity, and simple structure practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

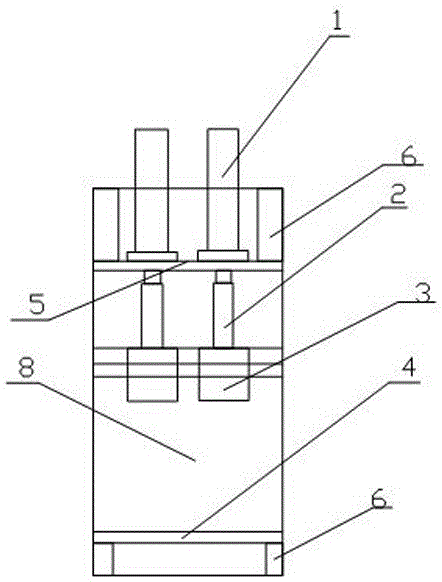

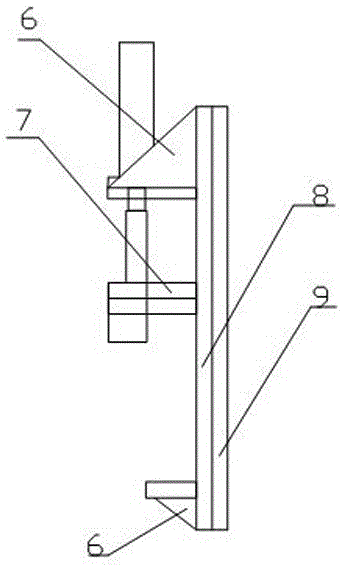

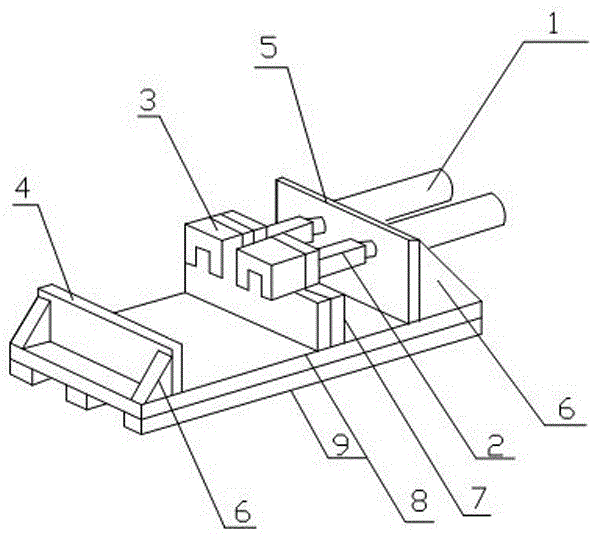

[0022] Example 1, such as Figure 1-3 , a pouring riser removal machine is characterized in that it includes an oil cylinder 1, a push rod 2, a push rod guide sleeve 3, a blank backing plate 4, an oil cylinder support plate 5, a blank rear support plate 7, a bottom plate 8, and the oil cylinder 1 Supported by the oil cylinder support plate 5, the oil cylinder support plate 5 is fixed on the upper end of the bottom plate 8, and the lower part of the oil cylinder support plate 5 is provided with the ejector rod 2 which is connected to the oil cylinder 1, and the ejector rod 2 is inserted into the ejector rod guide sleeve 3 for fixing. And the ejector pin guide sleeve 3 is fixed on one side of the blank back spreader 7 , the other side of the blank back spreader 7 is fixed on the middle end of the bottom plate 8 , and the blank backing plate 4 is fixed on the bottom end of the bottom plate 8 .

[0023] Further preferably, the number of said cylinders 1, ejector rods 2, and ejecto...

Embodiment 2

[0028] Example 2, such as Figure 1-3 , a pouring riser removal machine is characterized in that it includes an oil cylinder 1, a push rod 2, a push rod guide sleeve 3, a blank backing plate 4, an oil cylinder support plate 5, a blank rear support plate 7, a bottom plate 8, and the oil cylinder 1 Supported by the oil cylinder support plate 5, the oil cylinder support plate 5 is fixed on the upper end of the bottom plate 8, and the lower part of the oil cylinder support plate 5 is provided with the ejector rod 2 which is connected to the oil cylinder 1, and the ejector rod 2 is inserted into the ejector rod guide sleeve 3 for fixing. And the ejector pin guide sleeve 3 is fixed on one side of the blank back spreader 7 , the other side of the blank back spreader 7 is fixed on the middle end of the bottom plate 8 , and the blank backing plate 4 is fixed on the bottom end of the bottom plate 8 .

[0029] Further preferably, the number of said cylinders 1, ejector rods 2, and ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com