A semi-automatic assembly tooling for the back knob assembly of a car seat

A semi-automatic, car seat technology, used in assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as abnormal noise, difficulty in assembly rotation, and difficulty in knob zipper operation, avoiding abnormal noise and improving assembly. Accuracy and productivity, the effect of ensuring rotational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

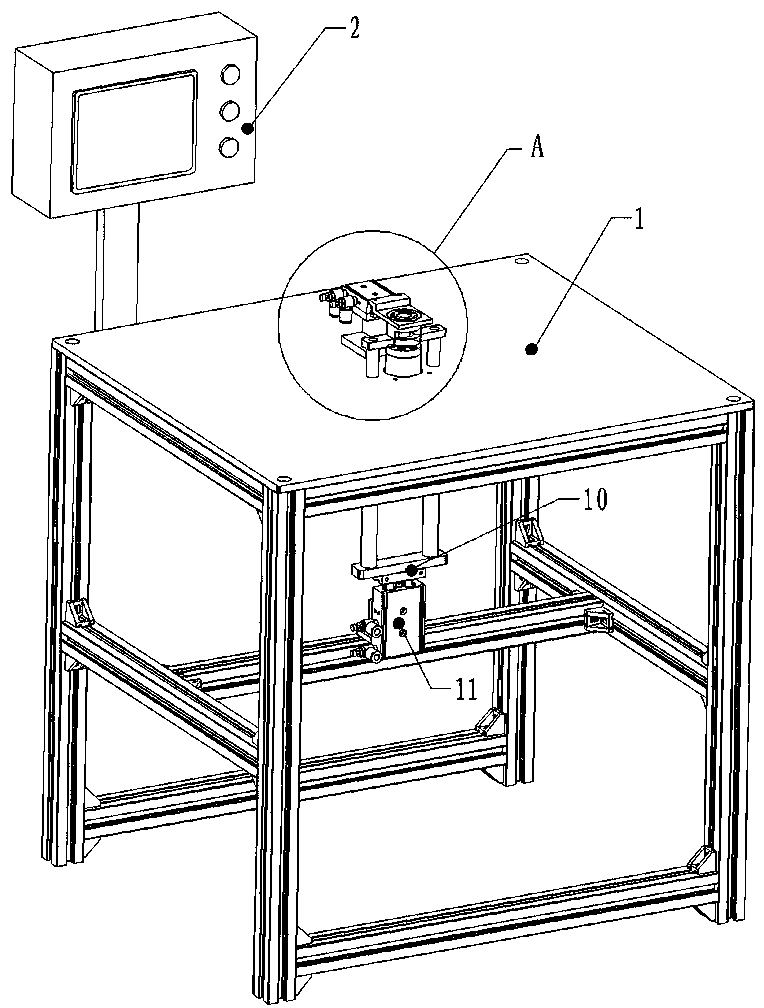

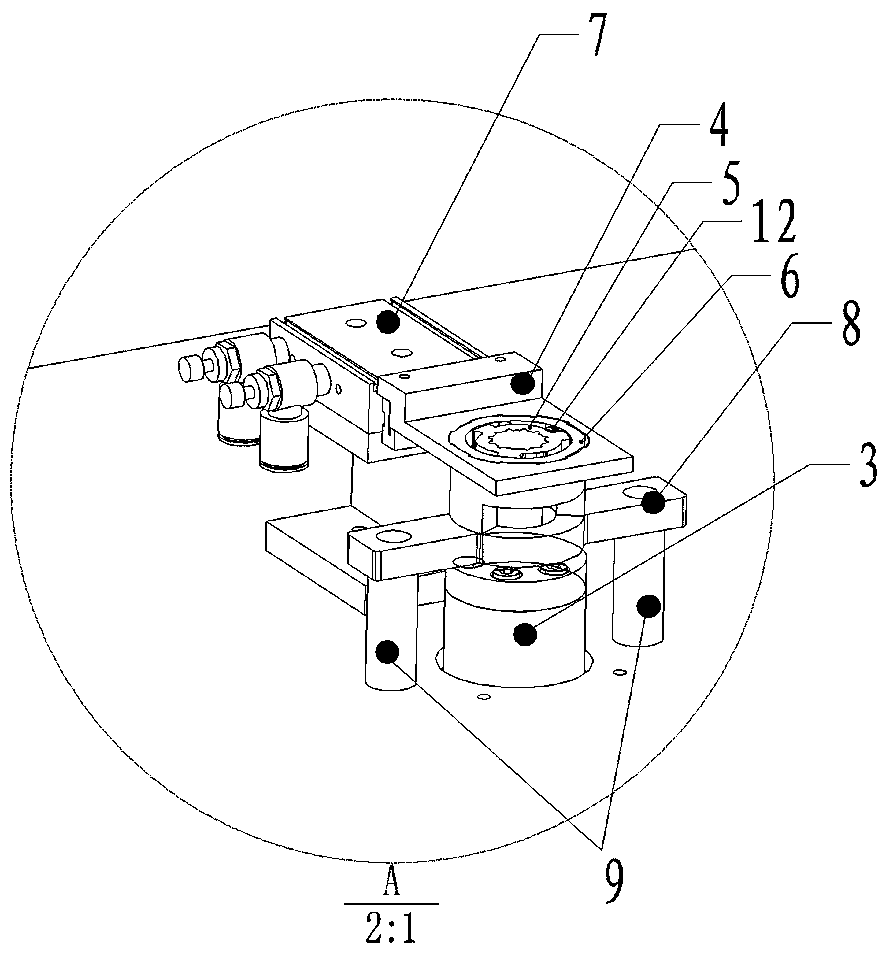

[0010] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The automotive seat back knob assembly semi-automatic assembly tooling includes a workbench 1 and a control system 2. The workbench 1 is provided with a rotating motor 3 and a fixed block 4. The fixed block 4 is arranged above the rotating motor 3. The output end of the rotary motor 3 is provided with a gear bar, the outer teeth of the gear bar match the inner teeth of the knob transmission disc 5, the fixed block 4 is provided with an installation opening, and the inner contour of the installation opening matches the outer contour of the knob positioning disc 6. Matched, the fixed block 4 is connected to the horizontal cylinder 7 in transmission; the installation port corresponds to the gear rod, so that the knob positioning disc 6 in the installation port is set on the outer circumference of the transmission d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com