Tyre cord fabric glue mixing system

A cord fabric and glue blending technology, which is applied in the field of cord cloth glue blending system, can solve the problems of poor temperature control accuracy of the glue blending device, affect the batching progress, and affect the glue performance, etc., to achieve simple structure, accurate material addition, and small error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

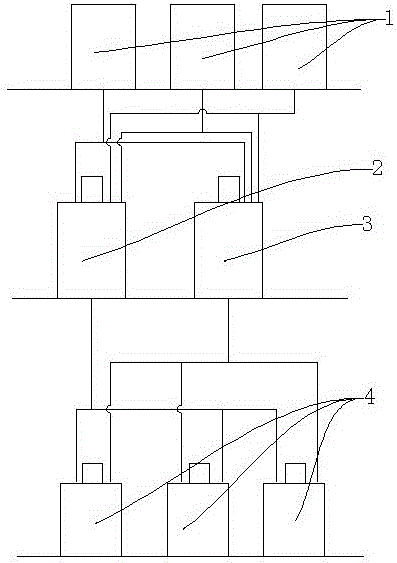

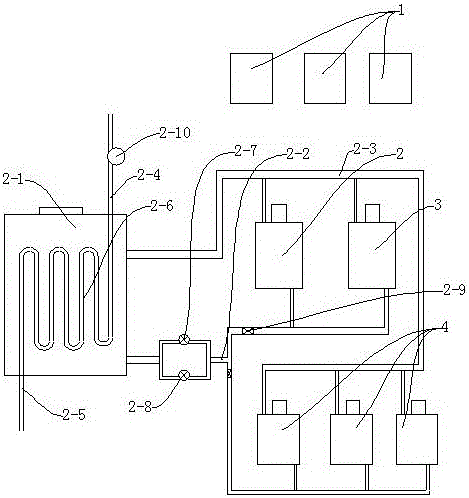

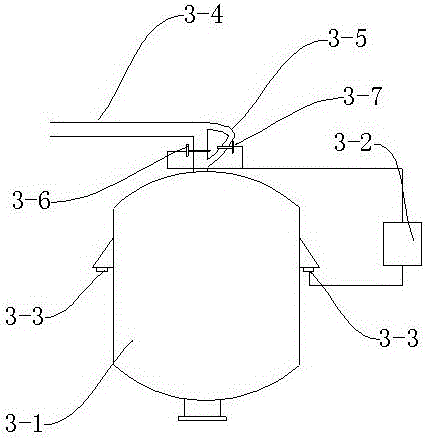

[0022] like figure 1 As shown, the cord glue blending system described in this embodiment includes a batching mechanism and a temperature control mechanism, and the batching mechanism includes a raw material tank 1 and a glue blending device; the glue blending device is divided into two types according to the process sequence, wherein One type includes a reaction tank 2 and a metering tank 3, the other includes three glue tanks 4, the metering tank 3 is used to prepare liquid A for glue preparation, the reaction tank 2 is used to prepare liquid B for glue preparation, and three Glue tank 4 is then used for the preparation of glue. The reaction tank 2 and the metering tank 3 are arranged on the middle floor, the raw material tank 1 is arranged on the upper floor of the floor where the reaction tank 2 and the metering tank 3 are located, and the glue tank 4 is arranged on the reaction tank 2 and the metering tank. The next floor of the floor where the tank 3 is located, the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com