Tubeless tire for motorcycle

A technology for motorcycle tires and inner tubes, applied in tire parts, reinforcement layers of pneumatic tires, vehicle parts, etc., can solve the problems of easy aging of rubber products, easy tire punctures, and limited weight, and reduce and increase the weight of the outer tire. Weight, the effect of reducing the amount of rubber used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

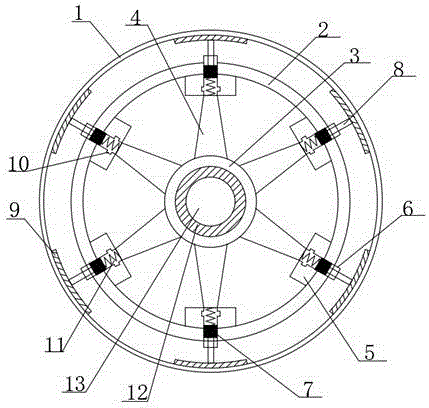

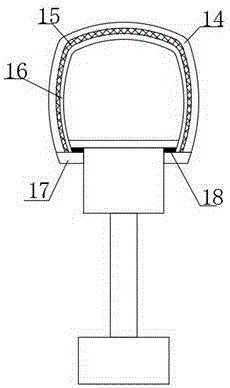

[0018] The invention provides a tubeless motorcycle tire, which is simple in structure and convenient to use, and is provided with an air chamber to replace the rubber inner tube, which can effectively increase the weight carried by a single tire, reduce the risk of tire blowout, and reduce the weight of the outer tire by half, thereby reducing the use of rubber. It is beneficial to environmental protection, and also has the effect of slowing down vibration and enhancing the friction between the tire and the ground.

[0019] In order to better understand the above technical solutions, the above technical solutions will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0020] like Figure 1-Figure 2 As shown, a tubeless motorcycle tire described in this embodiment includes a carcass 1, a rim 2, a hub 3 and a spoke 4, the carcass 1 is hollow inside, and the inner side of the carcass 1 is fixed on the rim 2 and A closed space is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com