PLC-control-based electric flat carriage with two independent-driving wheels arranged diagonally

An independent drive, electric flat car technology, applied in motion deposition, power plant, vehicle components and other directions, can solve the problems of electromagnetic relay safety hazards, lack of in-situ rotation, easy deviation of electric flat cars, etc., to achieve a simple and reliable structure , neat and beautiful layout, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the preferred embodiments shown in the accompanying drawings.

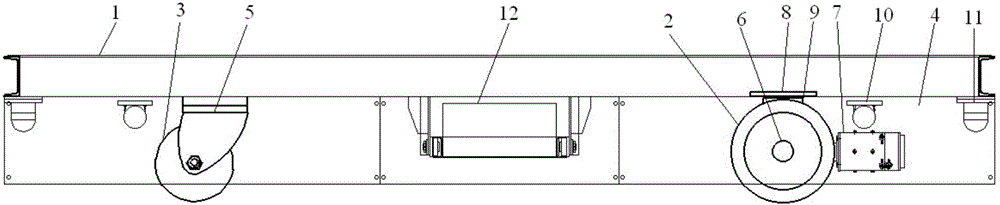

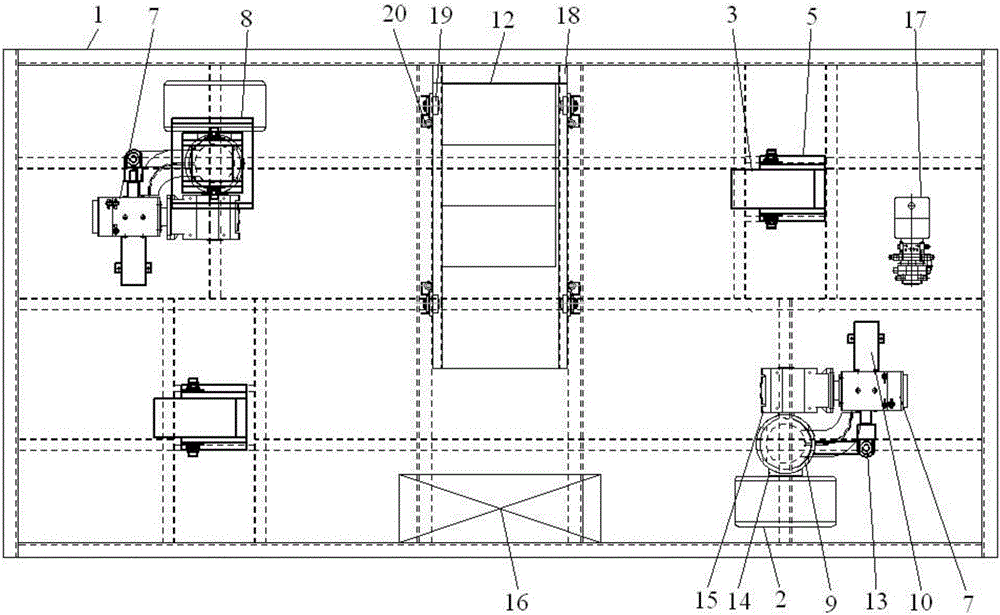

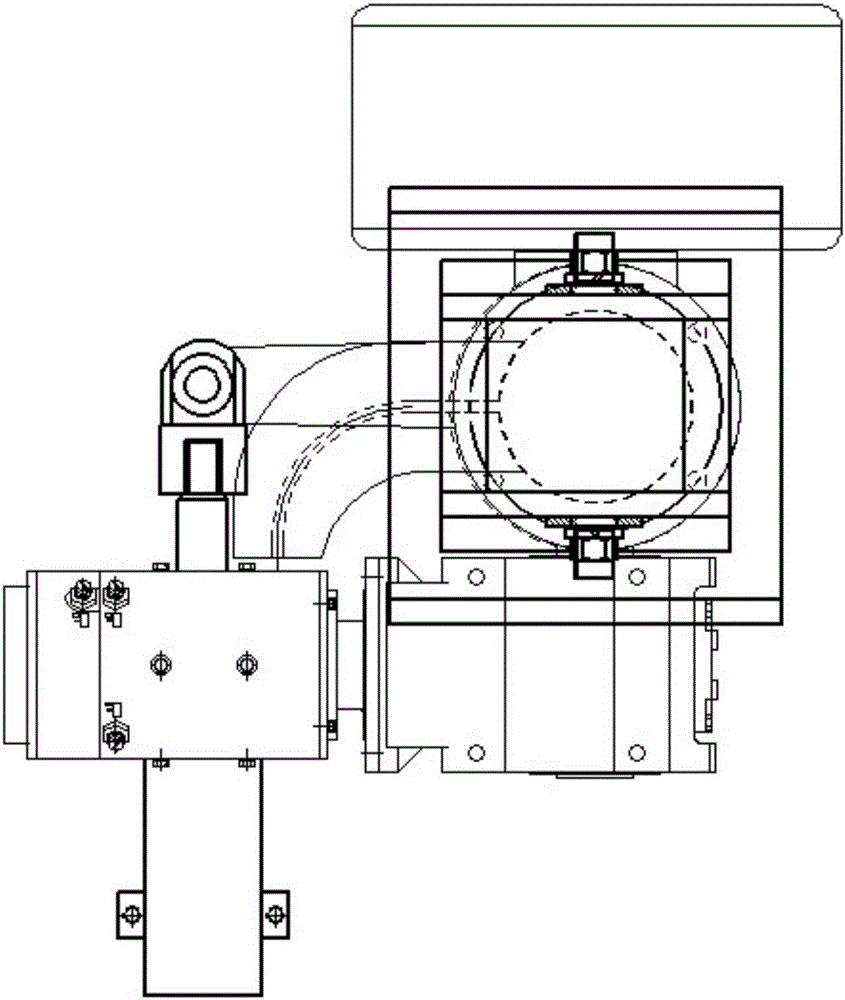

[0022] Such as figure 1 — Figure 4 , a two-wheel independently driven electric flat car with diagonal arrangement based on PLC control, including a frame 1, two driving wheels 2 arranged at the bottom of the frame 1 and arranged diagonally, two 1 Universal wheels 3 arranged diagonally at the bottom, an independent power drive mechanism and an independent steering mechanism arranged on one side of each driving wheel 2 and connected to the driving wheel 2, a PLC electronic control device installed at the bottom of the frame 1 Cabinet 16 and a drawer type battery box 12 installed on the bottom of vehicle frame 1.

[0023] The universal wheel 3 is fixed on the bottom of the vehicle frame 1 through the mounting support seat 5, and the driving w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com