Transformable motorcycle frame

A motorcycle and frame technology, applied in motorcycles, motor vehicles, bicycles, etc., can solve problems such as fatigue and inability to change riding posture, achieve reliable safety performance, change the drag distance of the front wheel, and change the shape of the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

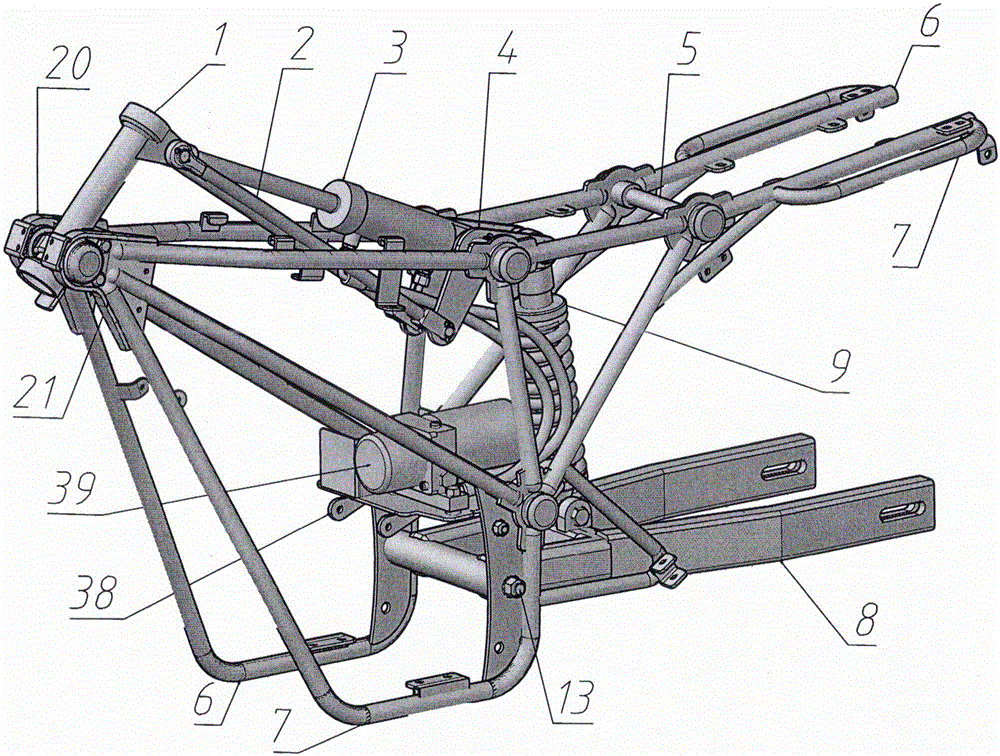

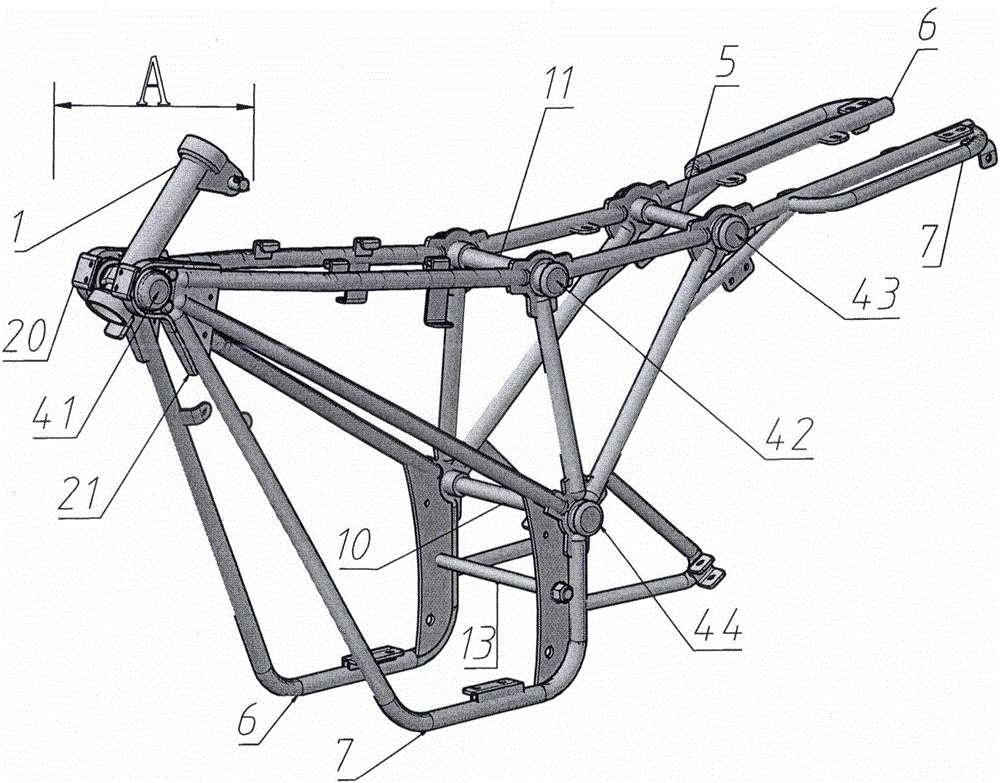

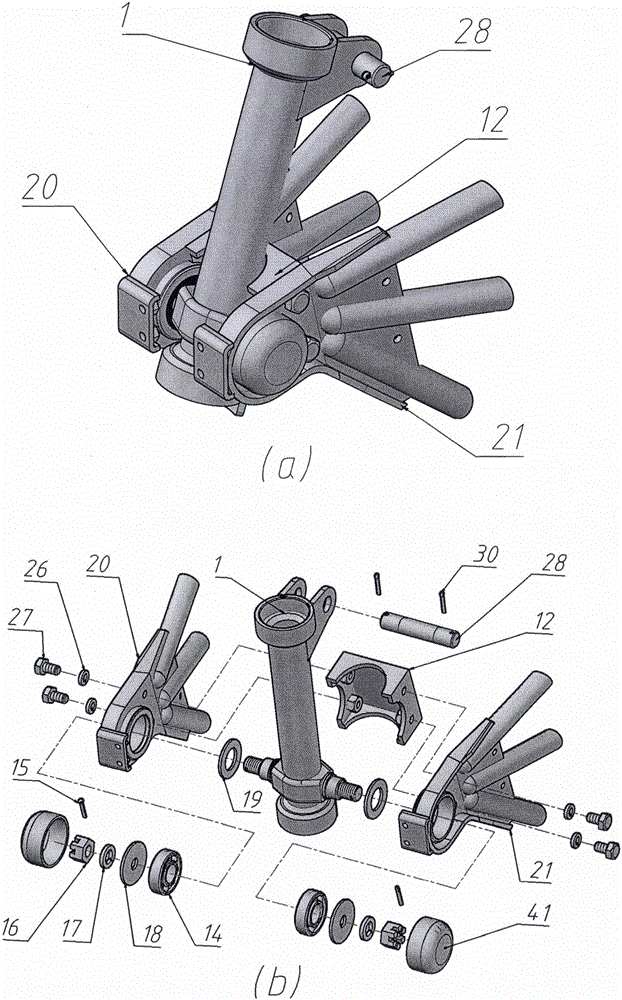

[0029] The specific embodiment of the present invention is shown in accompanying drawing, is made up of left frame 6, right frame 7, linkage mechanism (1,2,3,4,8,9,39), connecting shaft (1,5,10,11) , 13), composed of connecting blocks 12; it is characterized in that the left frame 6 and the right frame 7 are mirror-symmetrical independent structures, which are respectively composed of high-quality frame tubes and connecting plates with plug-in welding, and on each frame There are five connection points corresponding to each other; the cross connection shaft 1, the connection block 12, the main connection shaft 11, the rear connection shaft 5 and the lower connection shaft 10, on the respective corresponding connection points, connect the left frame 6 and the right frame 7 are connected into a complete and firm space frame structure.

[0030] The two ends of the horizontal axis of the cross connection shaft 1 are connected with the bearing 14 at the connection points 6.1 and 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com