Embracing-type strapping machine

A strapping machine and machine head technology, applied in the field of wrapping strapping machines, can solve the problems of inconvenient manual operation, high investment cost, large strapping machine body, etc., and achieve simple strapping action process, low equipment investment cost, simple and light structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

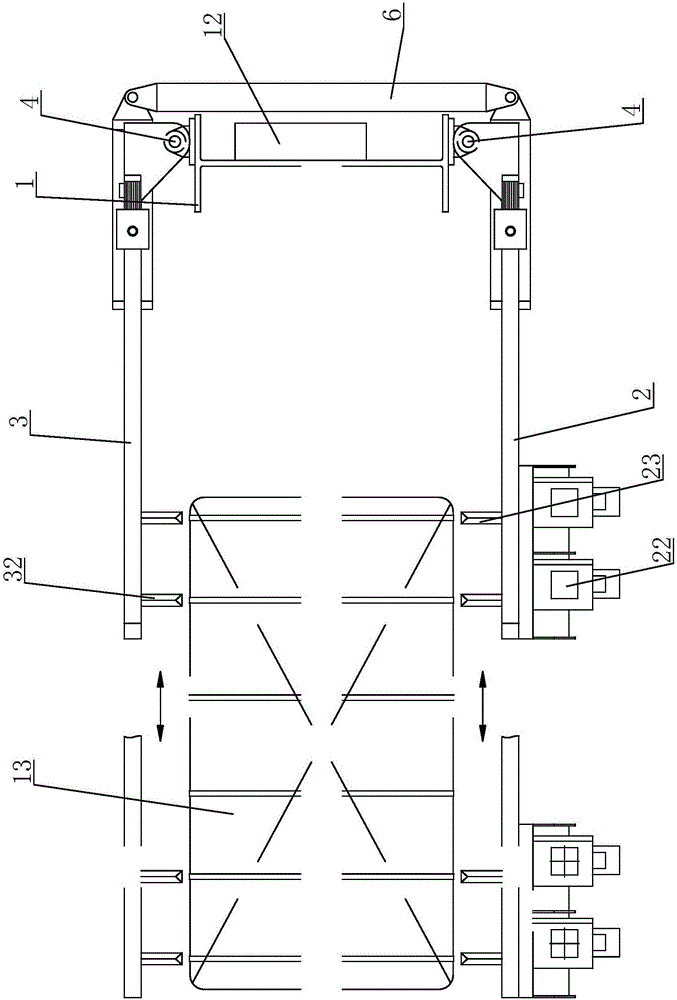

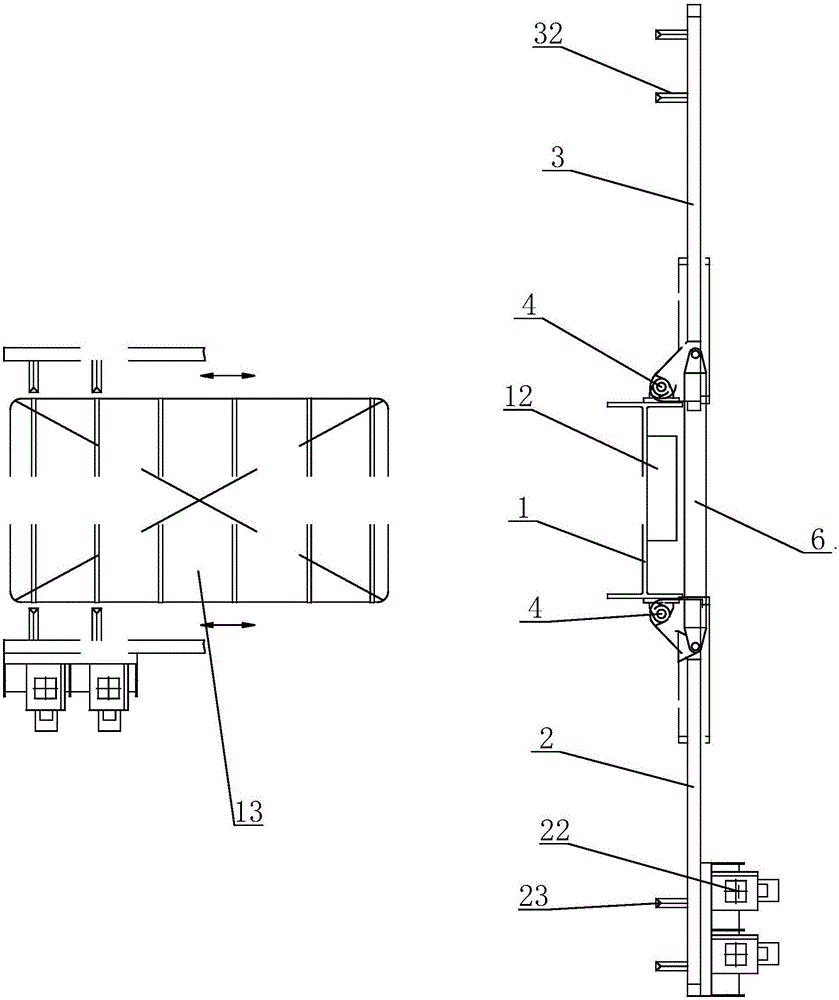

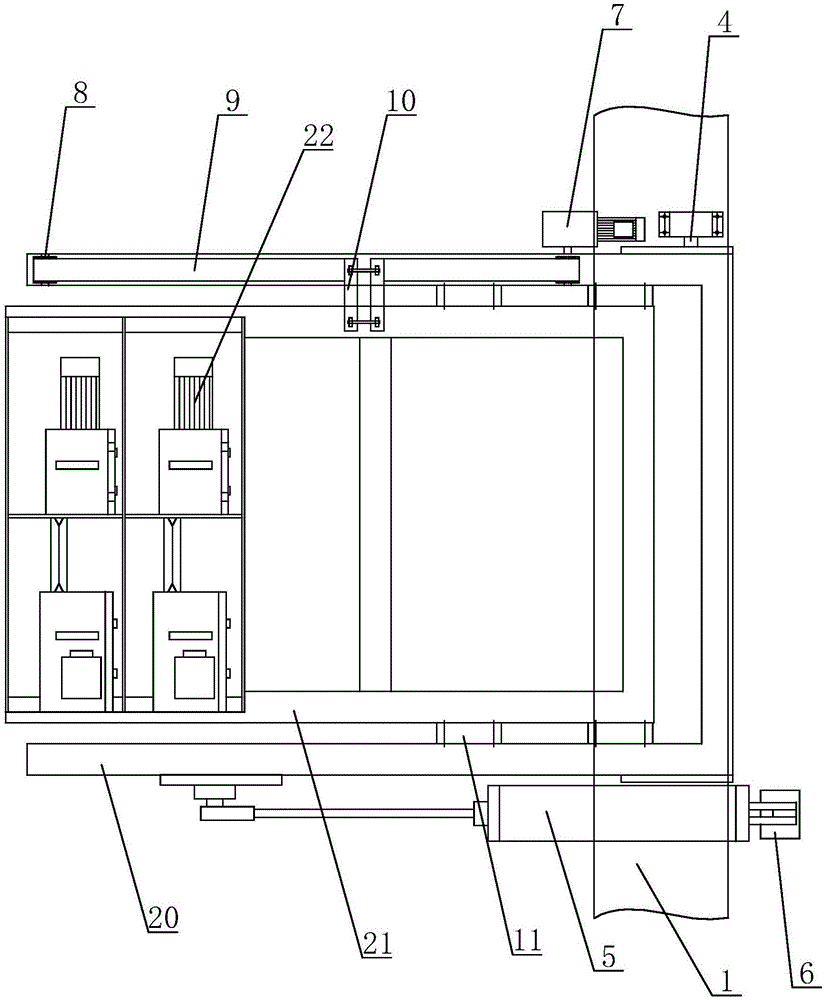

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] see Figure 1 to Figure 4 As shown, in this embodiment, a kind of embracing strapping machine includes the main pressure column 1 of the baler, that is, the column of the original baler is used as the base, and the two sides of the main pressure column 1 of the baler are correspondingly hinged with a strapping unit 2 And the belt guide unit 3, the strapping unit 2 includes the first rotating frame 20 hinged on one side of the main pressure column 1 of the packing machine through the rotating shaft 4, and the first rotating frame 20 is provided with a Sliding first sliding bracket 21, the front end of the first sliding bracket 21 is provided with two strapping heads 22 at intervals, and the strapping head 22 is arranged on the first rotating frame 20 in cooperation with the strapping head 22. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com