Even-distributed blanking type melon and fruit automatic packing machine and packing method

A blanking and cartoning machine technology, used in packaging, food packaging, transportation and packaging, etc., can solve the problems of bumping, low packing efficiency, accumulation on one side of the box, etc., to achieve uniformity without leaving gaps , The effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

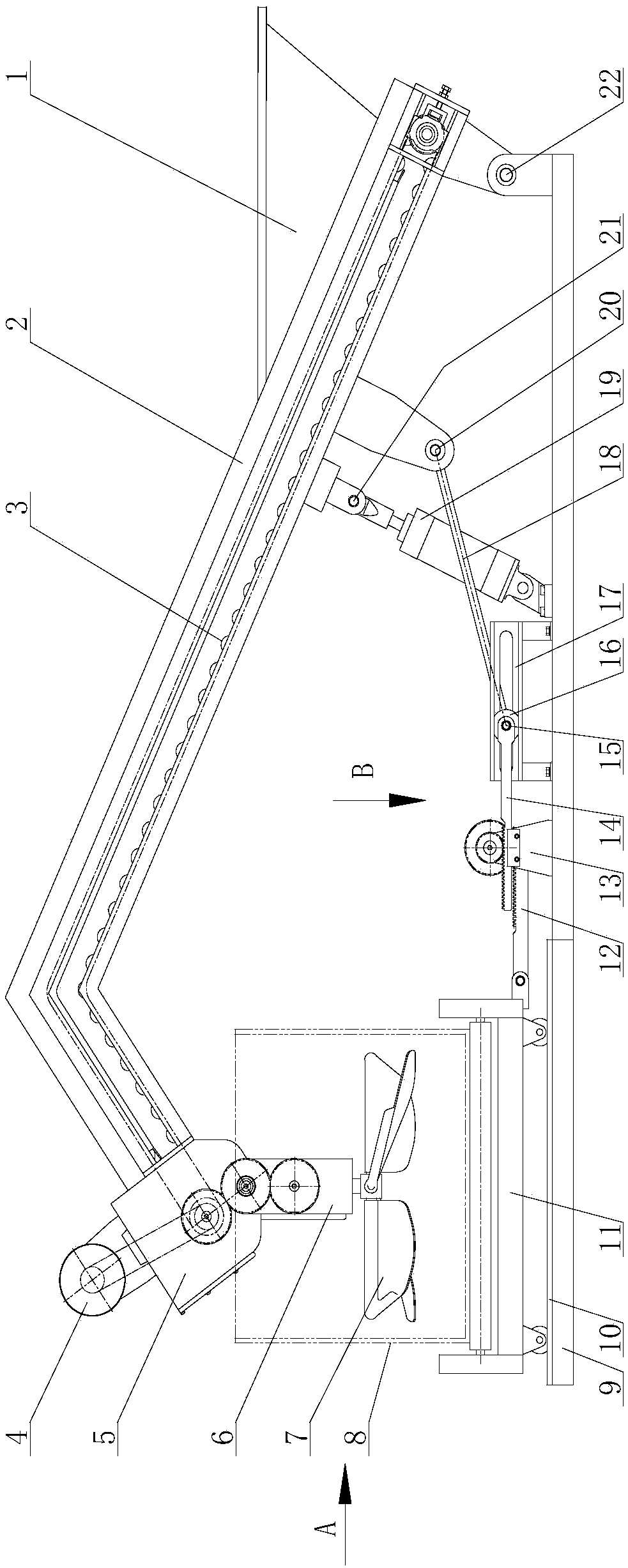

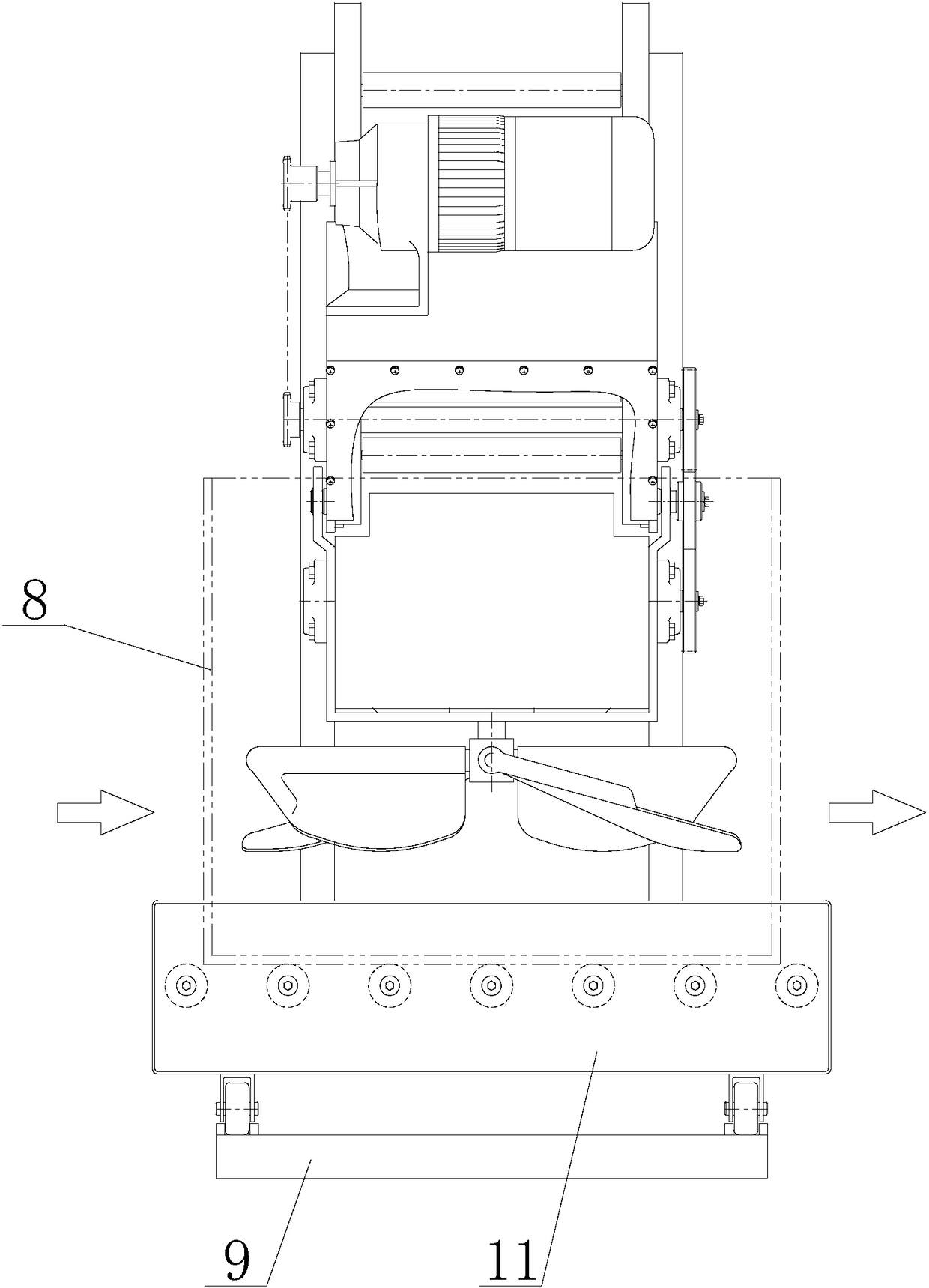

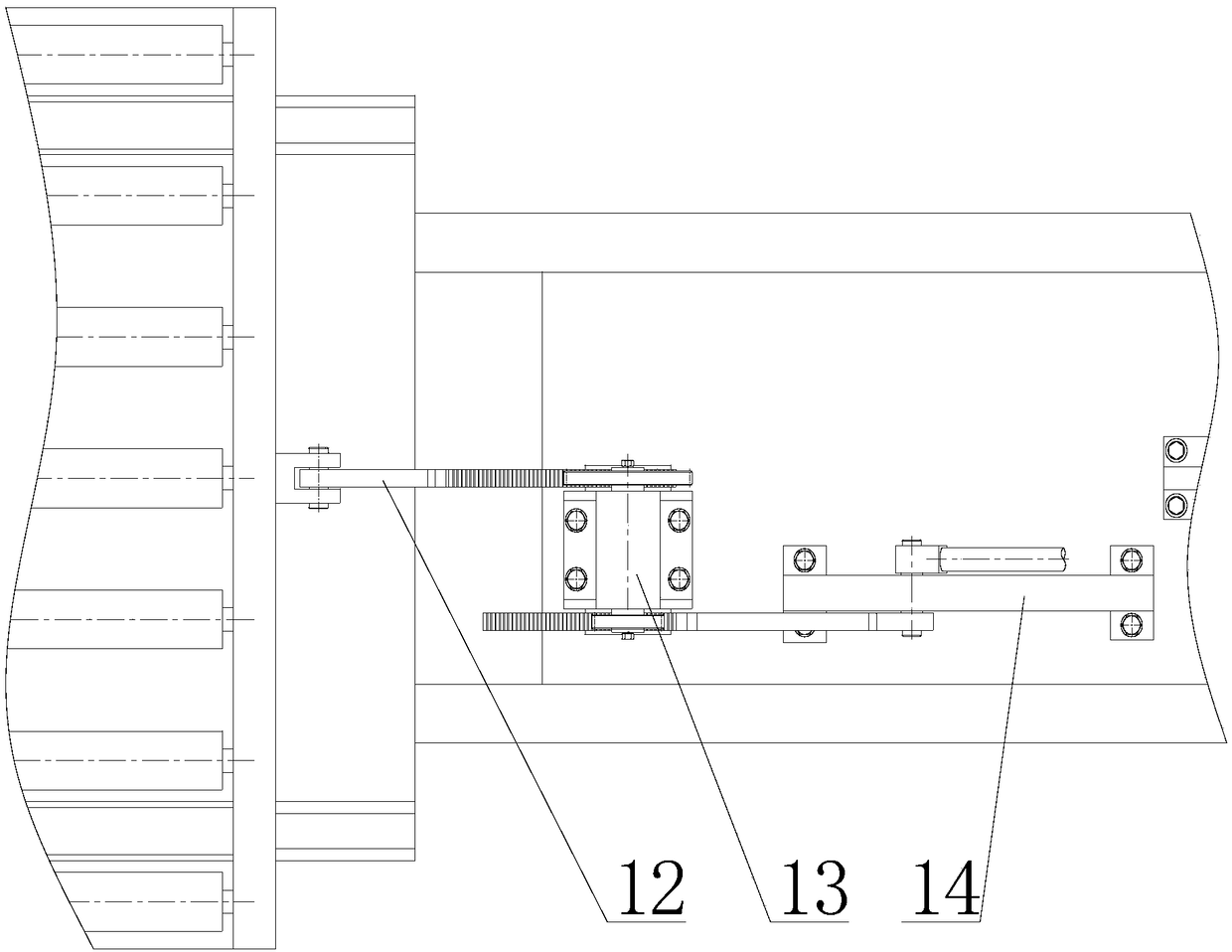

[0046] In this embodiment, a uniformly distributed blanking type melon and fruit automatic boxing machine and the boxing method realized thereof, such as Figure 1-12 As shown, its specific structure and principle are as follows:

[0047] 1. The overall structure of the equipment

[0048] Such as Figure 1~3 As shown, the even-distributed blanking type melon and fruit automatic boxing machine is mainly composed of four parts, which are the feeding and conveying mechanism, the material distribution device, the packing box positioning device and the lifting and shifting mechanism.

[0049] (1) Feed conveying mechanism

[0050] The feeding and conveying mechanism is essentially an inclined roller conveyor, which consists of two sections: the inclined upward conveying section and the downward curved conveying section near the discharge port.

[0051] The feeding and conveying mechanism is mainly composed of a feeding trough, a conveying body and a conveying roller, and its powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com