Polytetrafluoroethylene filament doup structure filter material base cloth and preparation method thereof

A technology of polytetrafluoroethylene and filament, which is applied in the textile field, can solve the problems of high temperature-resistant filter material, such as high weight, unreachable performance, and high price, so as to overcome poor cohesion, improve product quality, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

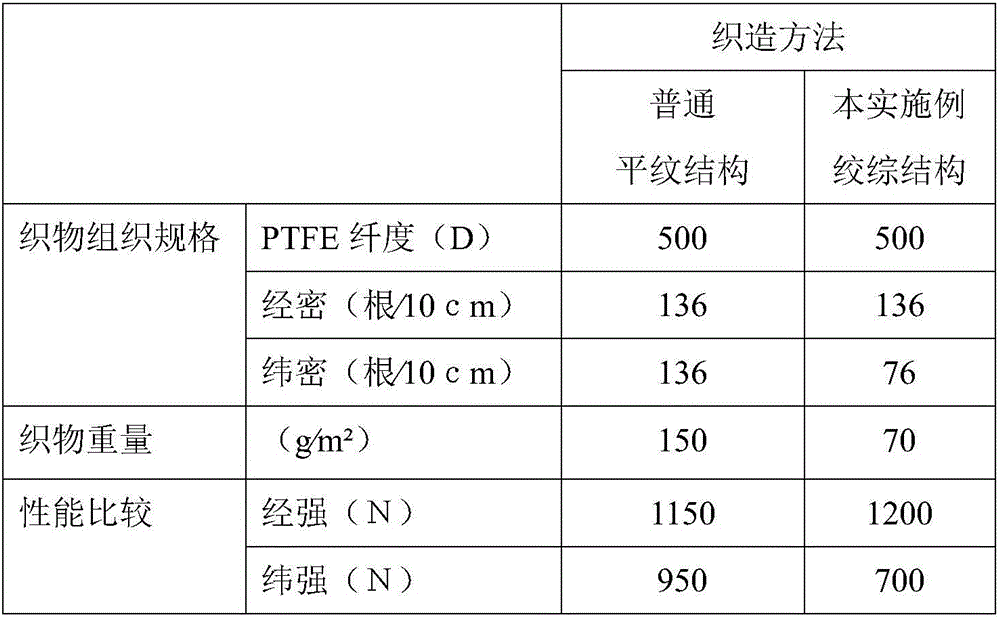

Embodiment 1

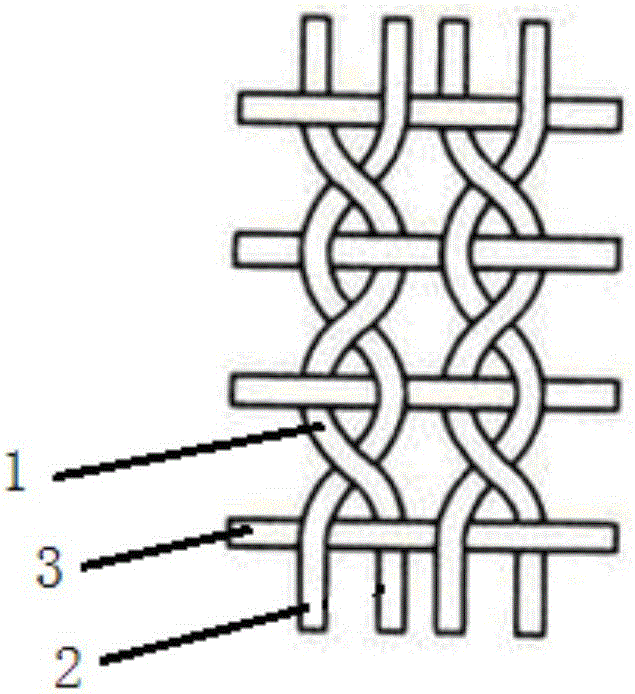

[0020] The utility model relates to a polytetrafluoroethylene filament twisted heddle structure filter material base cloth, which is composed of two systems of twisted warp and ground warp. When weaving, the position of the ground warp does not change, and the twisted warp is sometimes on the left side of the ground warp, and sometimes on the right side of the ground warp.

[0021] The weaving method adopted by the twisted heddle structure base fabric is to weave a weft yarn every time the twisted warp changes its left and right positions;

[0022] When the twisted heddle structure base fabric is put on the machine, the warp yarns of the twisted heddle part need to be threaded in two steps. First, the ground warp and the twisted warp are respectively inserted into the ordinary healds at the rear, and then inserted into the twisted heddle. Among them, the heddle worn by twisted sutras is the back heald, and the heald worn by the ground warp is the ground heald. According to th...

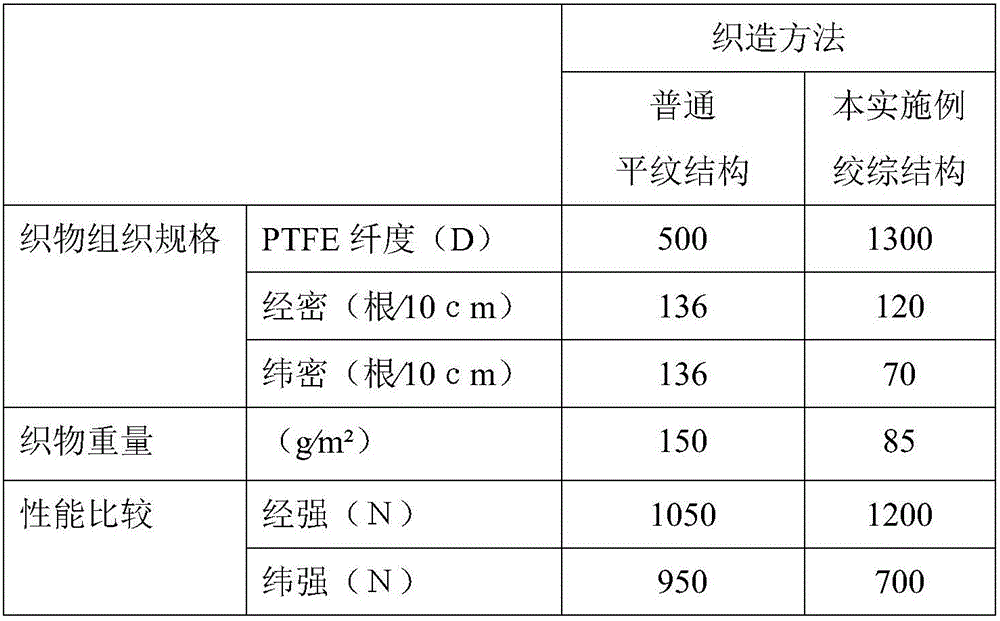

Embodiment 2

[0032] The utility model relates to a polytetrafluoroethylene filament twisted heddle structure filter material base cloth, which is composed of two systems of twisted warp and ground warp. When weaving, the position of the ground warp does not change, and the twisted warp is sometimes on the left side of the ground warp, and sometimes on the right side of the ground warp.

[0033] The weaving method adopted by the twisted heddle structure base fabric is to weave a weft yarn every time the twisted warp changes its left and right positions;

[0034] When the twisted heddle structure base fabric is put on the machine, the warp yarns of the twisted heddle part need to be threaded in two steps. First, the ground warp and the twisted warp are respectively inserted into the ordinary healds at the rear, and then inserted into the twisted heddle. Among them, the heddle worn by twisted sutras is the back heald, and the heald worn by the ground warp is the ground heald. According to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com