Accurate adjustment device and installation method for rails

A technology of precise adjustment and track, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of using too many backing plates, difficult adjustment, slow construction speed, etc., and achieves convenient assembly and disassembly, high molding quality, and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

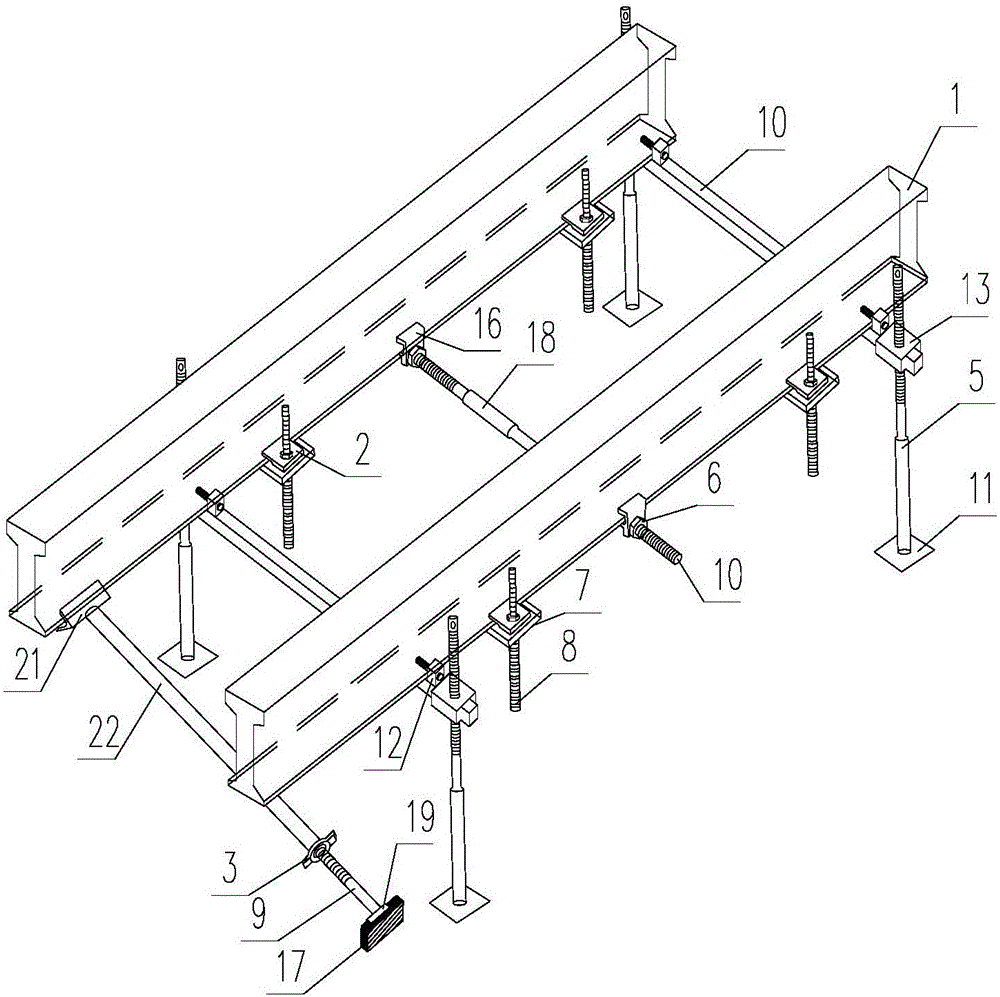

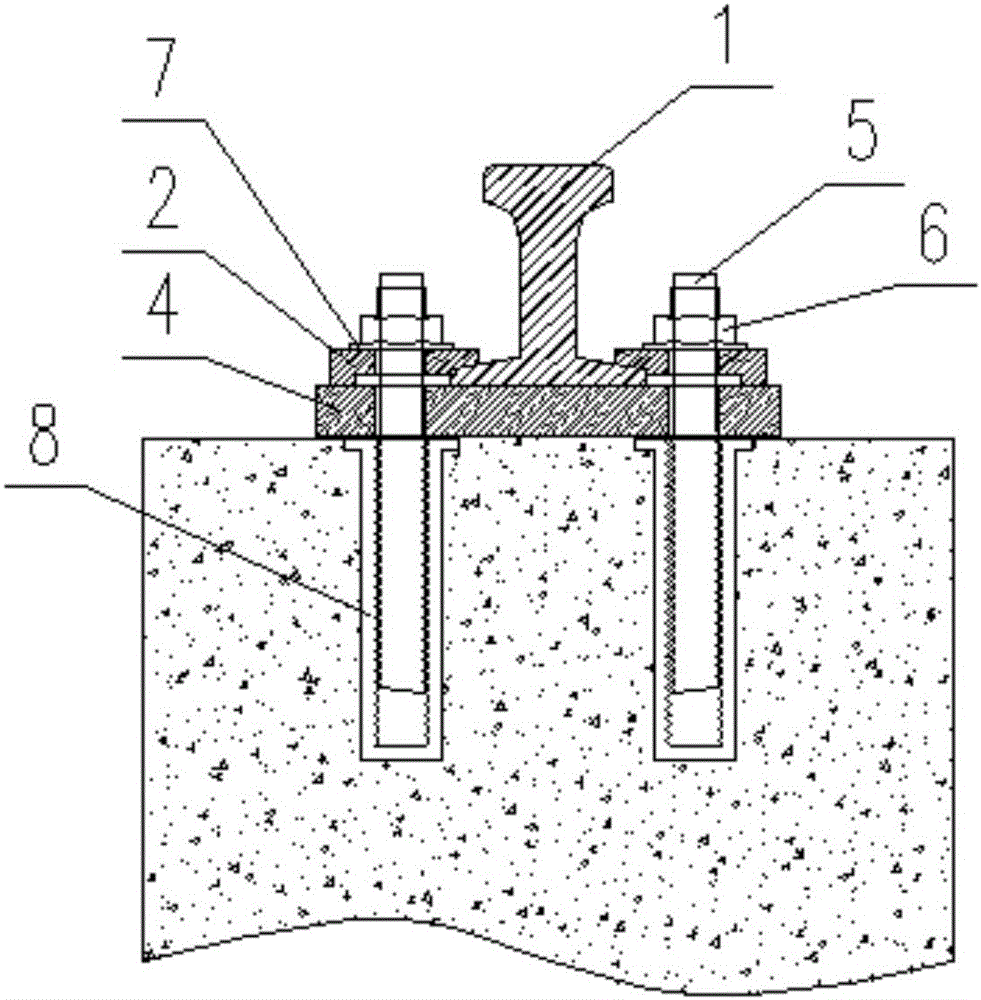

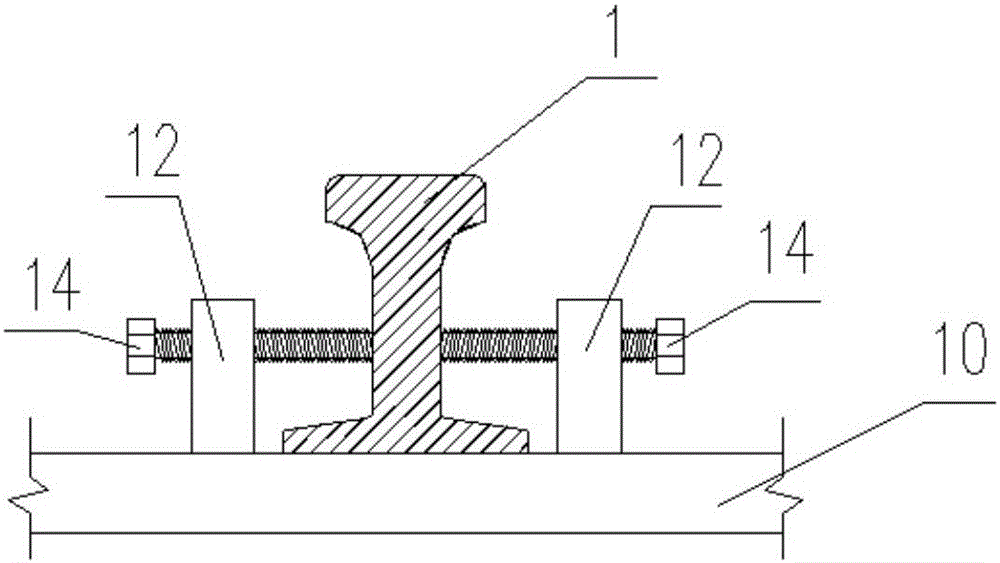

[0033] like Figure 1-6 As shown, a track precision adjustment device of the present invention includes a track 1, a vertical positioning system, a horizontal spacing positioning bar, embedded parts and oblique supports, and the vertical direction of the track is provided with a vertical positioning system, so The position between the above-mentioned rails is provided with a horizontal spacing positioning rod, the inner side of the rails is installed with oblique supports, and the underside of the rails is installed with embedded parts

[0034] The device includes a track 1, a vertical positioning system, a horizontal spacing positioning rod, embedded parts and oblique supports, the vertical direction of the track 1 is provided with a vertical positioning system, and the position between the tracks 1 is provided with a horizontal spacing positioning rod, the inner side of the track 1 is installed with an oblique support, and the underside of the track is equipped with embedded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com