Threading device for prestressed steel beam and threading method for prestressed steel beam

A technology of prestressed steel strands and threading devices, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., which can solve the problem that cannot be disassembled, can only be used once, the steel strands are entangled with each other, and the steel strands are knotted and blocked. and other problems, to achieve the effect of simple structure, prevent knotting and blockage, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

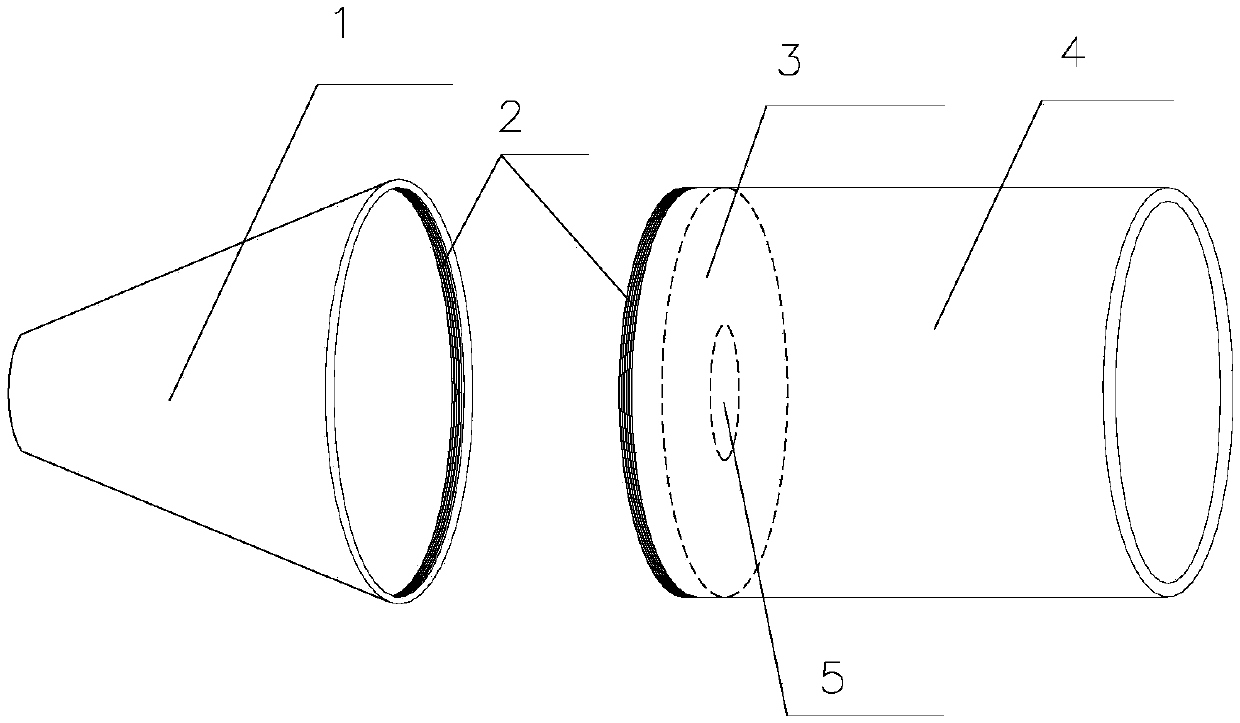

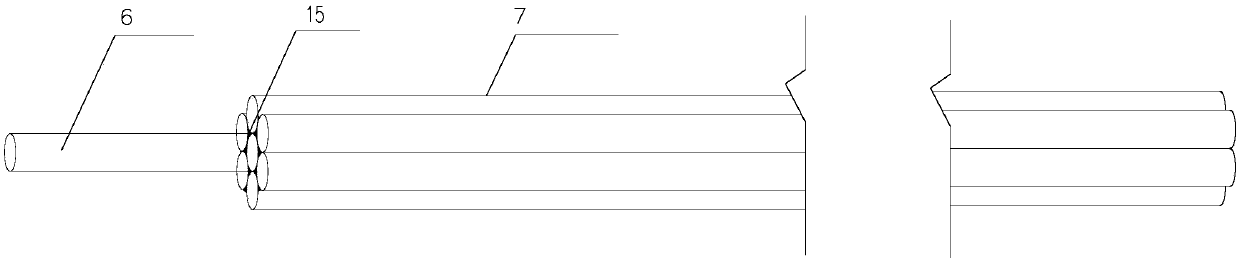

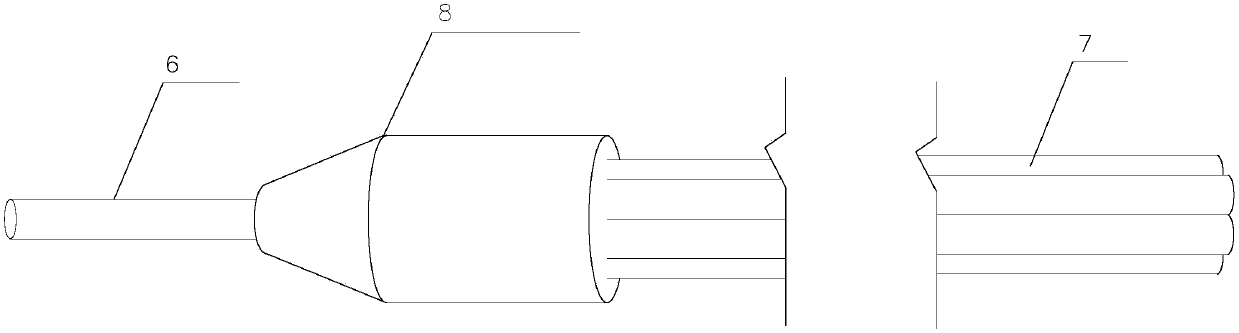

[0027] Such as figure 1 , Figure 7 As shown, a threading device for prestressed steel beams includes a steel beam probe 8 and a steel beam adjusting device 16, and the steel beam probe 8 includes a conical cylinder 1, a casing 4, and a steel beam baffle 3 , the tapered tube 1 is connected with the casing 4 by a screw, the steel bundle baffle 3 is fixed inside the casing 4, and a through hole 5 is arranged at the center of the steel bundle baffle 3; the steel bundle adjusting device 16 includes Intermediate plate 18, triangular bracket 19, brake universal wheel 17, triangular bracket 19 is fixed on the both sides of intermediate plate 18, brake universal wheel 17 is installed on the bottom of triangular bracket 19, and intermediate plate 18 is provided with different diameters. Dredge hole 20.

[0028] The tapered barrel 1 is made of stainless steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com