Composite reinforcing bar pre-tensioning method prestressed concrete pile with displaceable sleeves for connection

A composite reinforcement and sleeve connection technology, applied in sheet pile walls, structural elements, building components, etc., can solve the problems of unsatisfactory requirements, high brittleness, poor crack resistance, and poor corrosion resistance, and achieve pile-type mechanical properties. Reliable, direct force transmission of steel bar connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For the current prestressed piles equipped with non-prestressed steel bars, due to the unreasonable connection method of the non-prestressed steel bars, their mechanical properties are not reliable, especially when the pile is used for uplift piles, the axis of the pile body is under tension Or when the tension is small eccentrically, the tensile bearing capacity of the pile may not necessarily reach the calculated value.

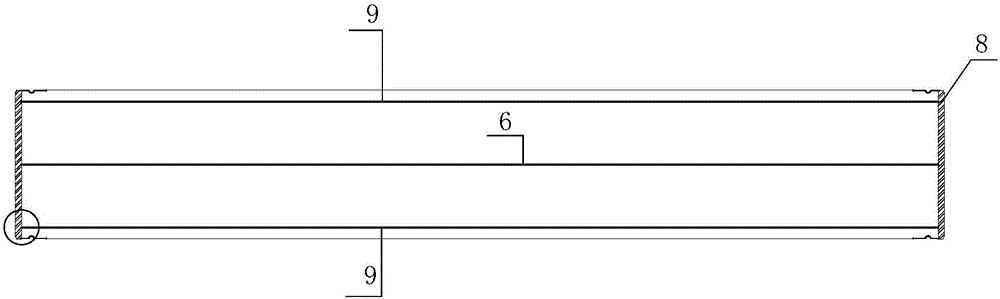

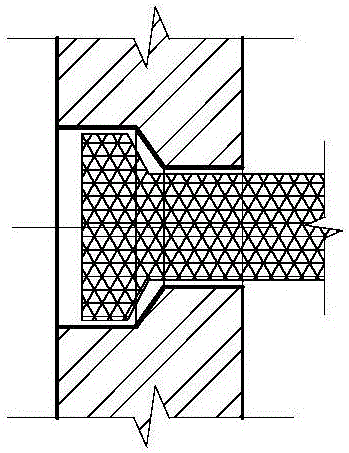

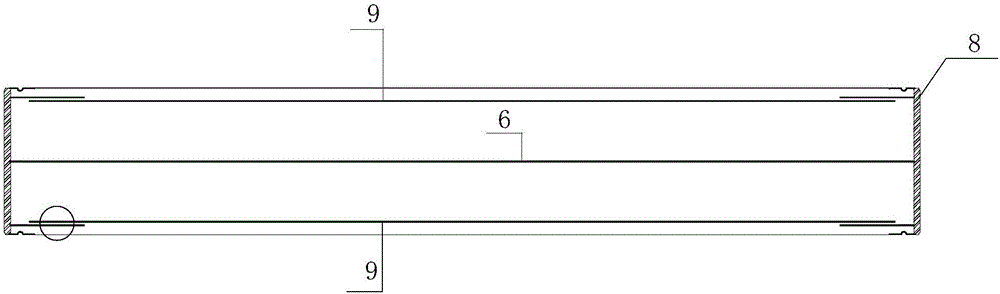

[0022] Such as Figure 5 As shown, a displaceable sleeve for connecting steel bars 1, one end of the steel bar 1 has a pier head 2, the sleeve 3 is composed of a first sleeve 4 and an integrally formed upper end of the first sleeve 4 The second sleeve 5 is composed of; the inner diameter of the first sleeve 4 is greater than the diameter of the pier head 2; the inner diameter of the second sleeve 5 is greater than the diameter of the steel bar 1, less than the diameter of the pier 2; the first set Internal thread is arranged in the pipe 4.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com