Sound insulation shed structure

A technology of sound booths and sound insulation screens, which is applied to building structures, industrial buildings, and substation rooms. It can solve the problems of inability to discharge heat from mobile power stations, inability to meet noise reduction and sound insulation, and limited sound insulation effects, and achieve light weight and energy saving. Good material and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below by means of specific embodiments:

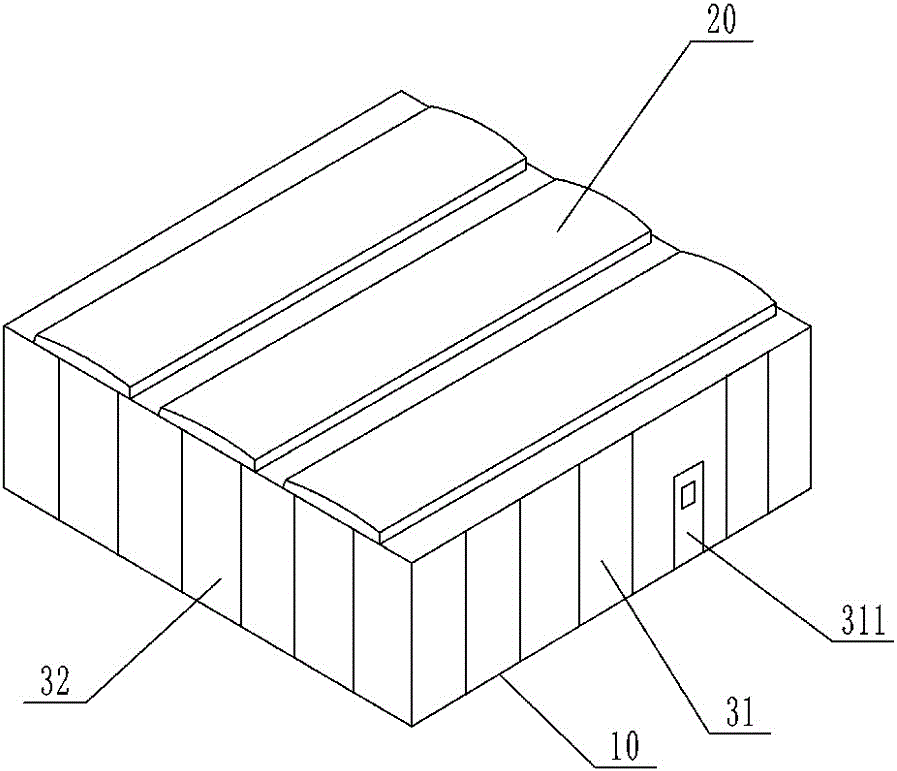

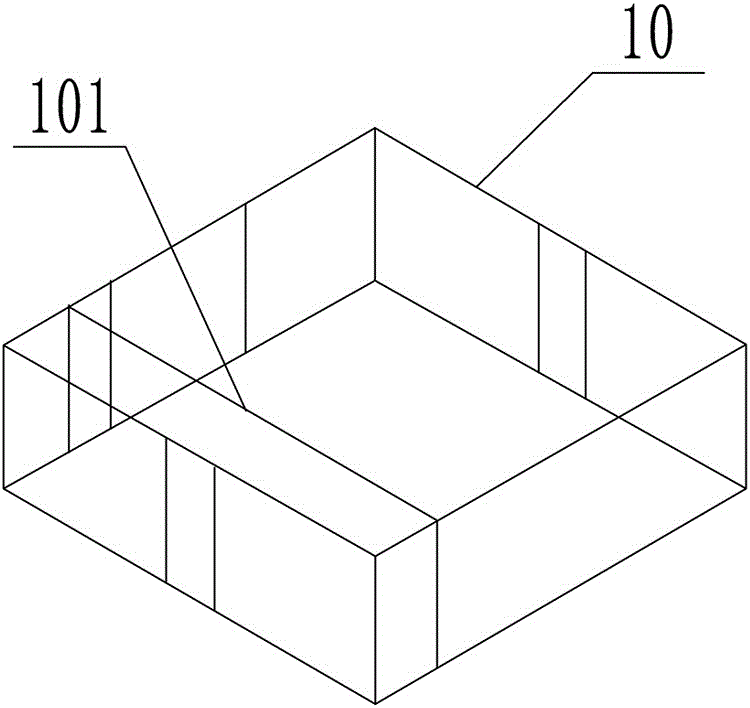

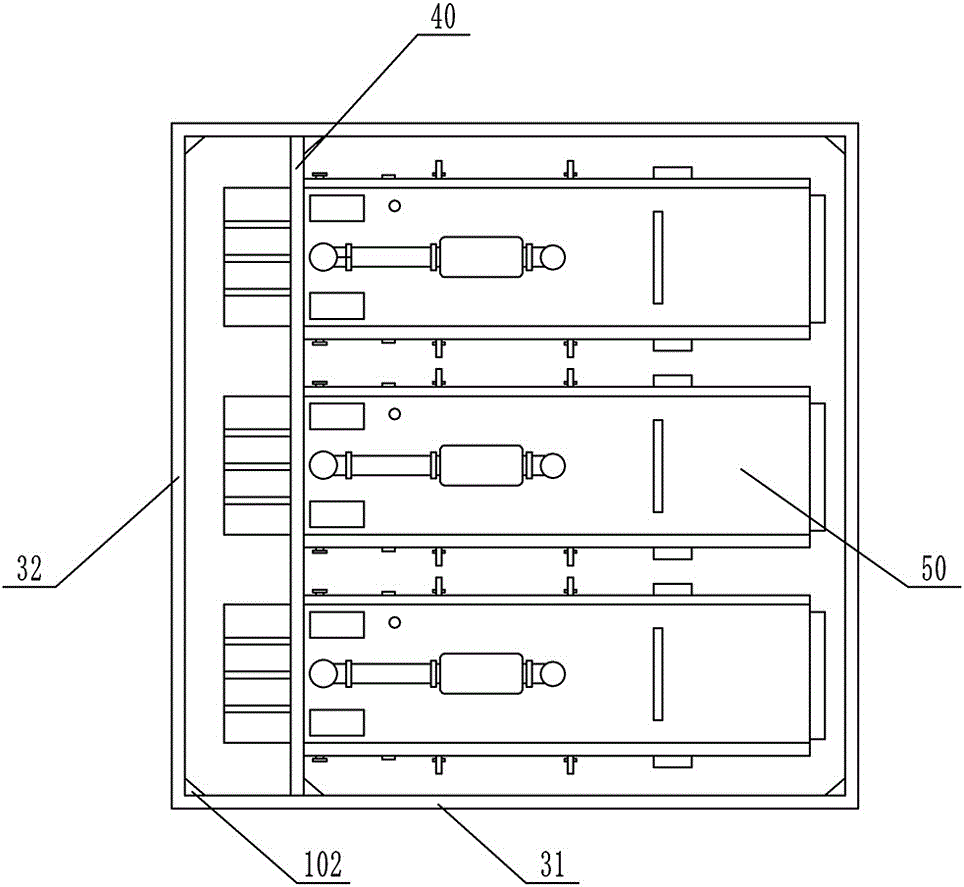

[0046] The reference numerals in the accompanying drawings of the specification include: skeleton 10, installation frame 101, corner plate 102, roof 20, rock wool sound-absorbing board 201, installation frame 202, first side wall 31, soundproof door 311, tempered glass 312, Gasket 313, glass fixing frame 314, handle 315, limit plate 316, second side wall 32, first sound insulation screen 40, gas motor 50, fourth sound insulation screen 60, sound insulation strip 601, corrugated board 602, fastener 603 , The sound-absorbing block 80, the first baffle 91, and the second baffle 92.

[0047] The embodiment eliminates the sound insulation booth mechanism basically as attached figure 1 , figure 2 , image 3 Shown:

[0048] The sound-absorbing booth mechanism includes a detachable frame 10 and a detachable sound-insulation component built on a bracket. Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com