Tunnel anti-freeze heat-insulation structure based on phase change temperature adjusting concrete and construction method

A technology of concrete and phase change temperature, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of increasing tunnel construction costs, prolonging the construction period, and deteriorating thermal insulation of thermal insulation materials, so as to save material purchase costs and save Construction cost, effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

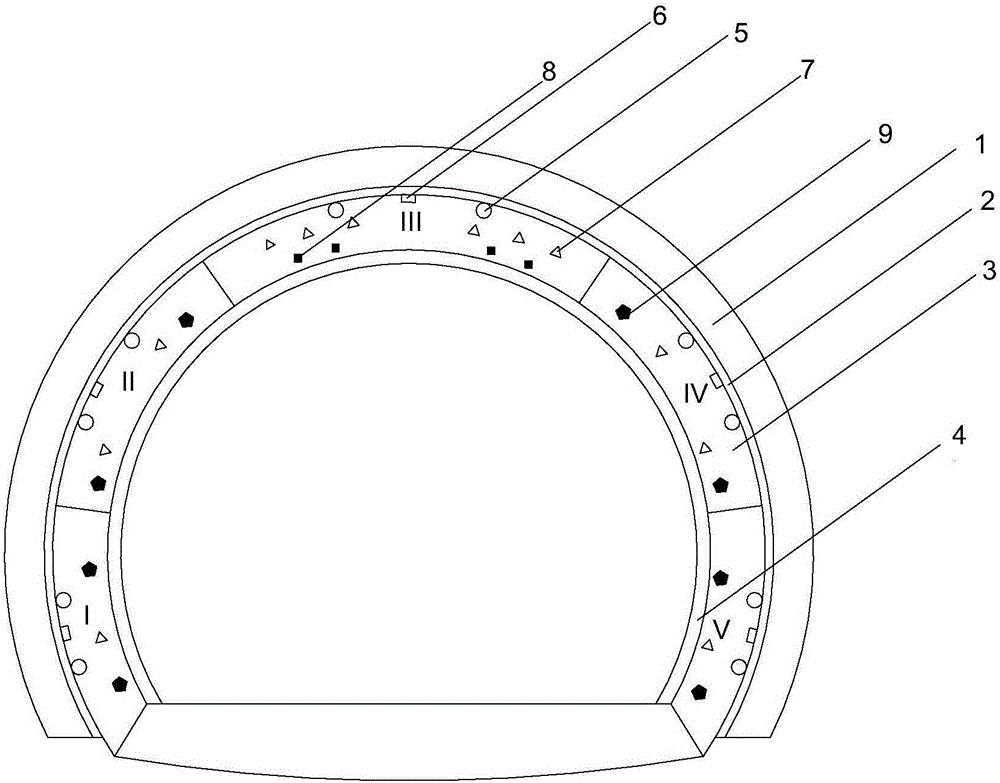

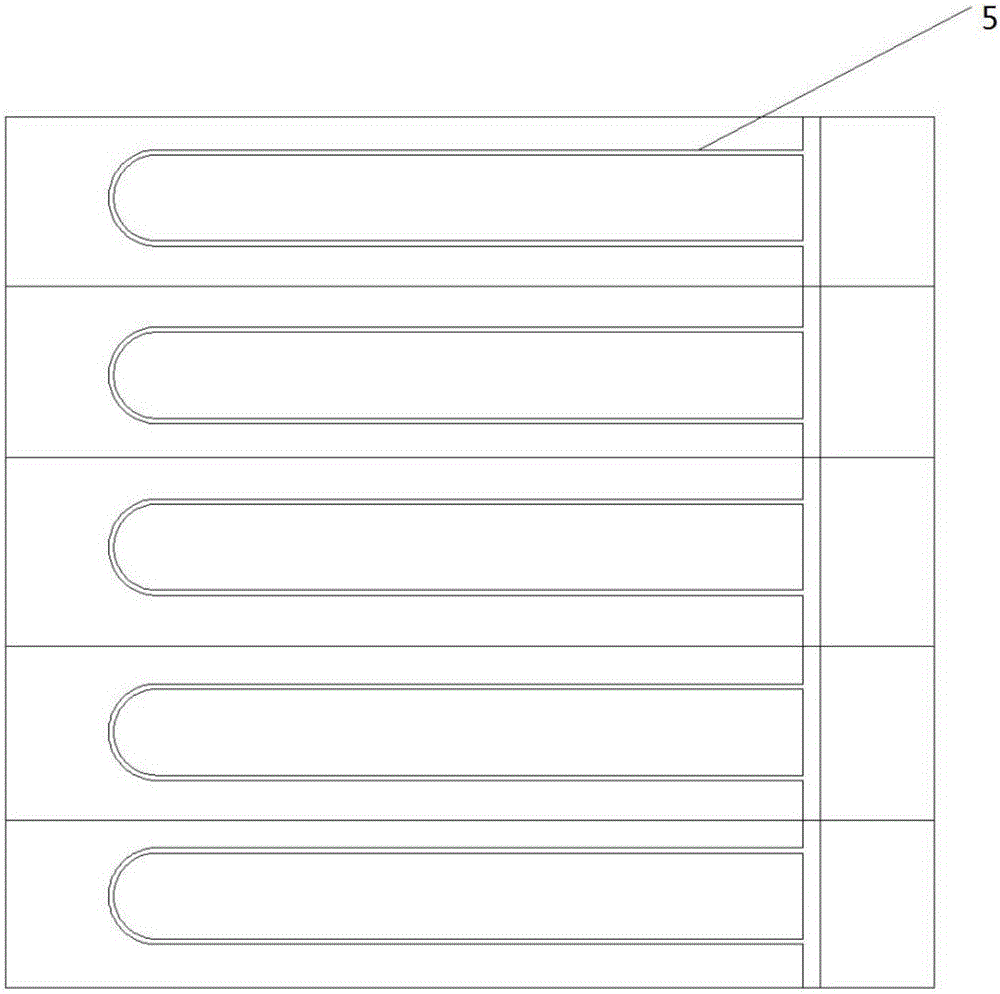

[0033] The antifreeze and thermal insulation structure of the tunnel based on phase change temperature-adjusting concrete in this implementation is as follows: figure 1 As shown, it includes the fireproof board 4, the second tunnel lining 3, the waterproof board 2 and the primary tunnel lining 1 arranged sequentially from the inside to the outside of the tunnel, wherein the concrete of the second tunnel lining 3 contains porous lightweight aggregate 7, the first phase change capsule 8 and the second phase change capsule 9, the porous lightweight aggregate 7, the first phase change capsule 8 and the second phase change capsule 9 are directly mixed into the corresponding concrete during construction.

[0034] The tunnel second lining 3 is composed of multiple regions in the ring direction, as shown in the figure I, II, III, IV, V five regions, the thermal properties of the tunnel second lining 3 in the adjacent regions are all different; the tunnel second lining 3 located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com