Fast liquid discharging valve of molten tin melting furnace

A technology of melting furnace and drain valve, which is applied in the direction of lifting valve, valve device, mechanical equipment, etc. It can solve the problems of harsh environment in the workshop, low energy utilization rate, and difficulty in guaranteeing the quality of large castings, etc., and achieves convenient operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

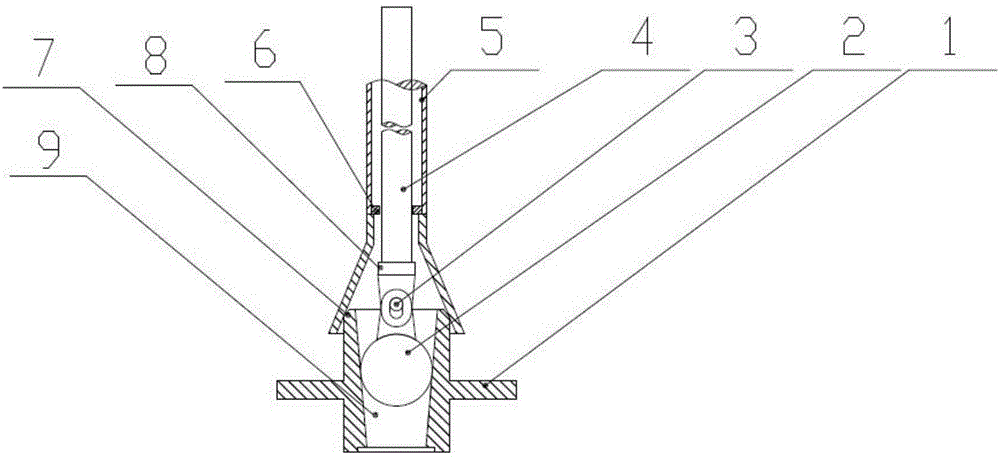

[0014] A rapid liquid discharge valve for a molten tin melting furnace, comprising a valve body 1, a valve core 2, a valve stem 4, a pivot pin 3 and a passive valve sleeve 5, characterized in that the valve body 1 is an inverted truncated cone-shaped inner Cavity 9, the inner cavity 9 is sealed by the valve core 2 placed in the valve body 1, the upper end of the valve core 2 is connected with the valve stem 4 that can move up and down through the shaft pin 3; A passive valve sleeve 5 that can move up and down with the valve stem 4 is provided. The inner wall surface of the lower peripheral opening of the passive valve sleeve 5 is in contact with the upper edge of the valve body 1, so that the passive valve sleeve 5 and the valve body 1 form a secondary seal. .

[0015] The valve core 2 is spherical or inverted conical.

[0016] The valve stem 4 includes a valve stem base 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com