Molded case circuit breaker final pressure testing mechanism

A molded case circuit breaker and testing mechanism technology, which is applied in the direction of force/torque/power measuring instruments, instruments, measuring devices, etc., can solve the problems of increased production costs, poor reliability and test rationality, rough appearance, etc., to ensure accurate Performance and reliability, simple and beautiful structure and appearance, and the effect of prolonging the service life

Inactive Publication Date: 2016-11-09

镇江立昌智能装备有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Since the contacts of the customer's products are manually assembled, there will inevitably be precision errors after assembly, resulting in inaccurate test results. In response to this situation, a variety of testing mechanisms have been designed in the industry, but generally the reliability and test rationality are poor, and the appearance is rough. , it is difficult to guarantee the qualification rate of the molded case switch. If things go on like this, it will not only reduce the reputation of the enterprise, but also cause an increase in the production cost of the enterprise

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

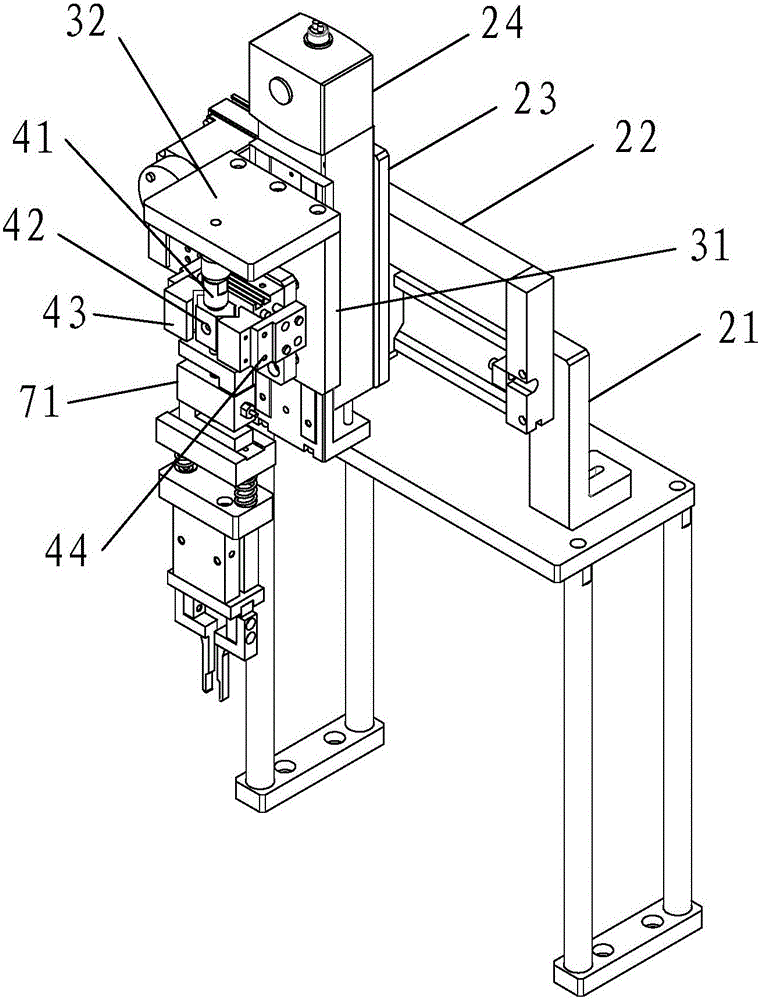

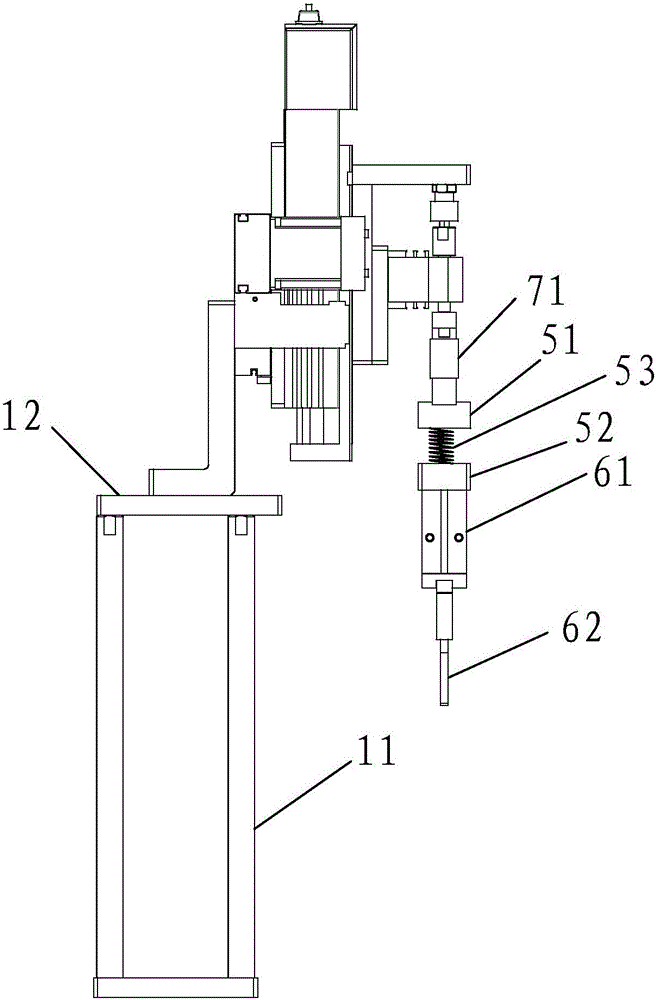

[0031] Such as figure 1 with figure 2 as shown,

[0032] First, the product enters the testing station and is automatically clamped. When the product is closed, the wide air claw 44 is in the clamped state, the air claw 61 is in the loosened state, and the gripper hand 62 is in the loosened state.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a molded case circuit breaker final pressure testing mechanism. The molded case circuit breaker final pressure testing mechanism comprises a supporting platform, an actuating mechanism arranged above the supporting platform, a connection mechanism arranged on one side of the actuating mechanism, an adjustment mechanism, a buffer mechanism and a clamping mechanism, wherein the adjustment mechanism, the buffer mechanism and the clamping mechanism are arranged on one side of the connection mechanism from top to bottom. A weight sensor is arranged between the buffer mechanism and the clamping mechanism. According to the invention, a mechanical and electrical combination control method and a rigid-flexible mixing combination method are used; the structure appearance is simple and beautiful; false test results caused by man-made reasons are avoided to the greatest extent; the service life of a test part is prolonged; and the accuracy and the reliability of test data are ensured.

Description

technical field [0001] The invention relates to the field of automatic testing of low-voltage molded case circuit breakers, in particular to a final pressure testing mechanism of low-voltage molded case circuit breakers. Background technique [0002] Molded case circuit breaker, also known as molded case switch, is a common protection circuit component. In order to maintain the reliability of the electrical contact of the molded case circuit breaker, prevent false connection or contact bouncing caused by the electric repulsion when encountering an instantaneous short-circuit current, after the molded case switch is manufactured, it is necessary to carry out a final pressure test to ensure Ensure safe and reliable use. [0003] Since the contacts of the customer's products are manually assembled, there will inevitably be precision errors after assembly, resulting in inaccurate test results. In response to this situation, various testing mechanisms have been designed in the i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01L5/00

CPCG01L5/0038

Inventor 周帆

Owner 镇江立昌智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com