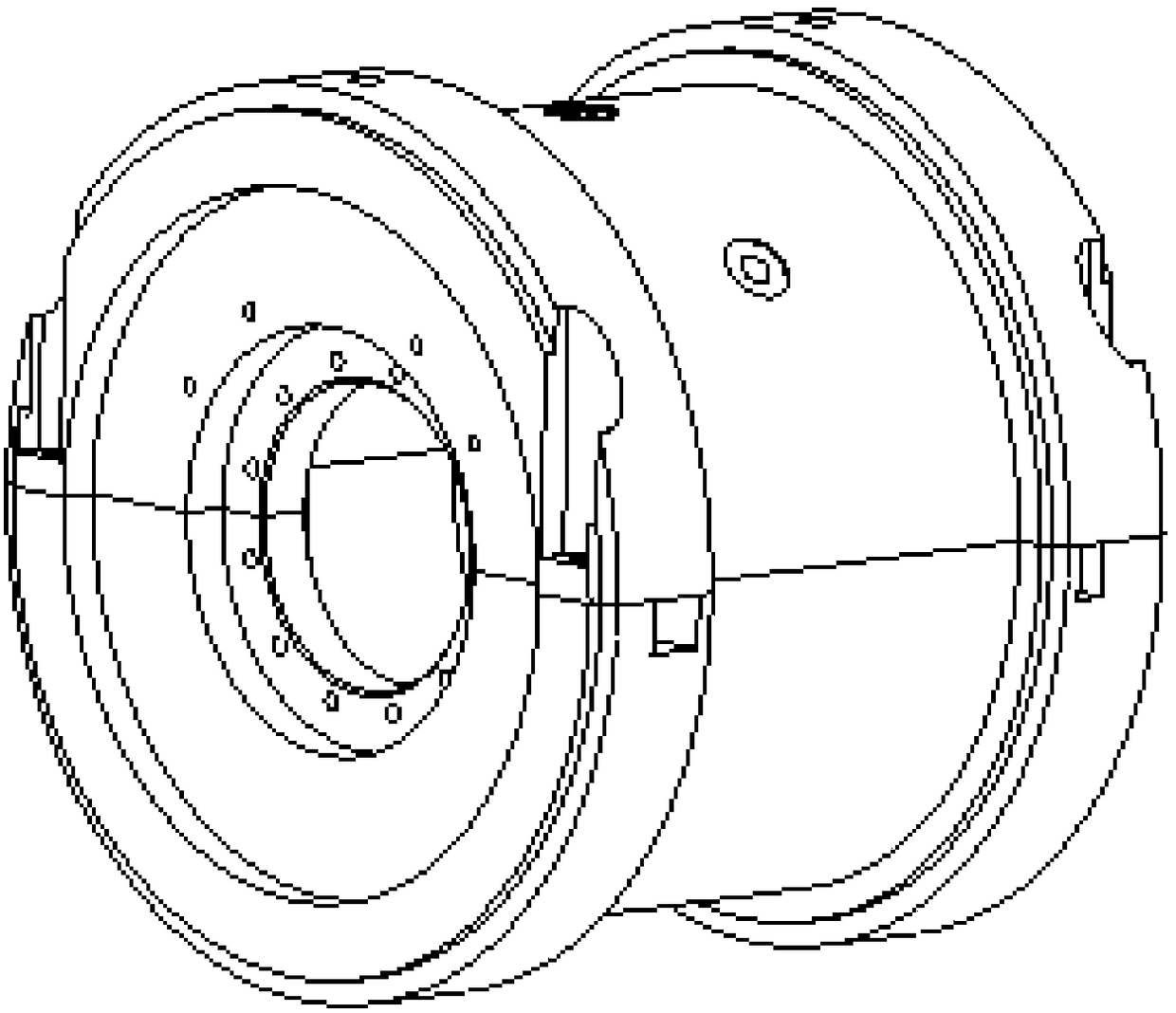

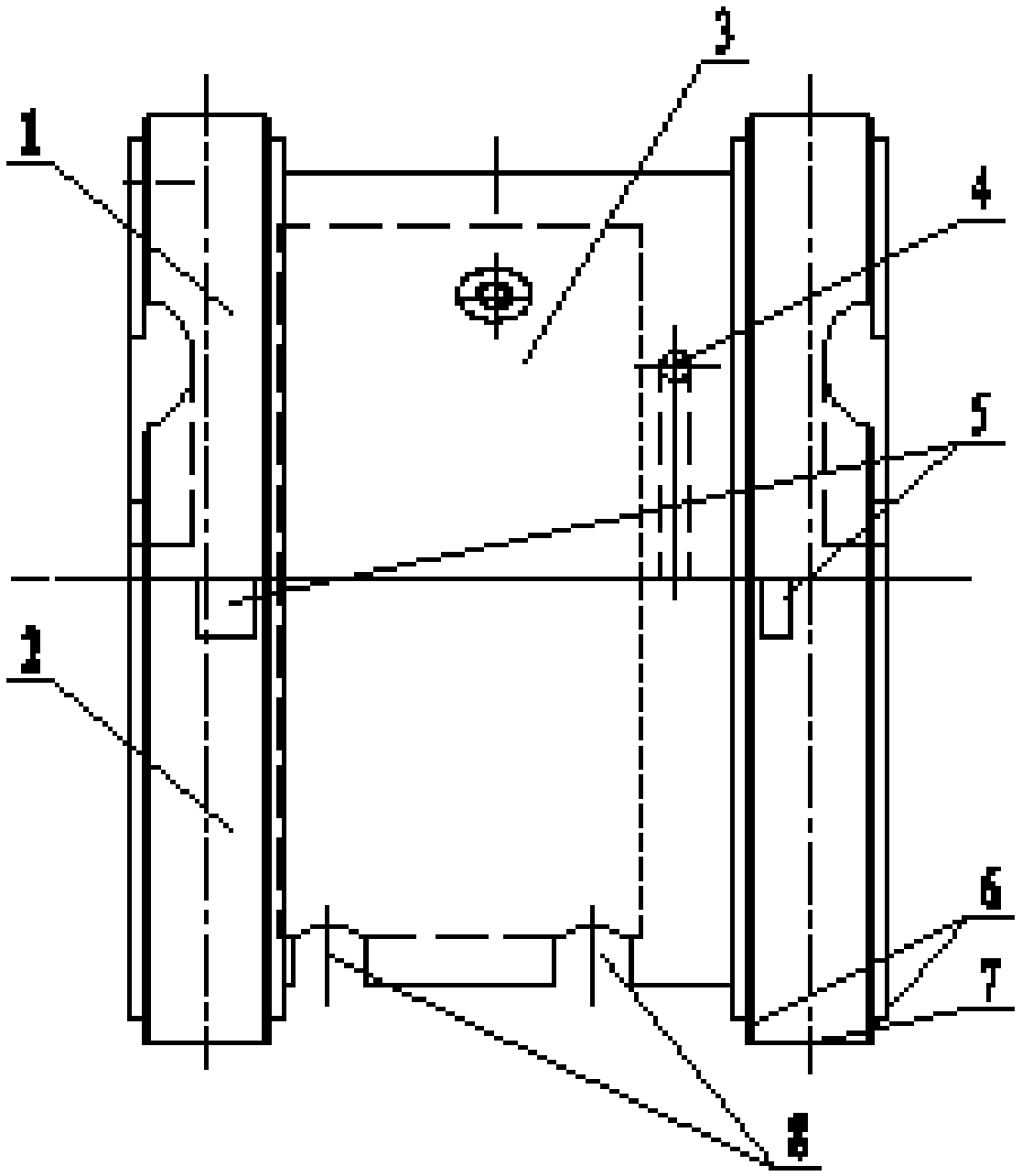

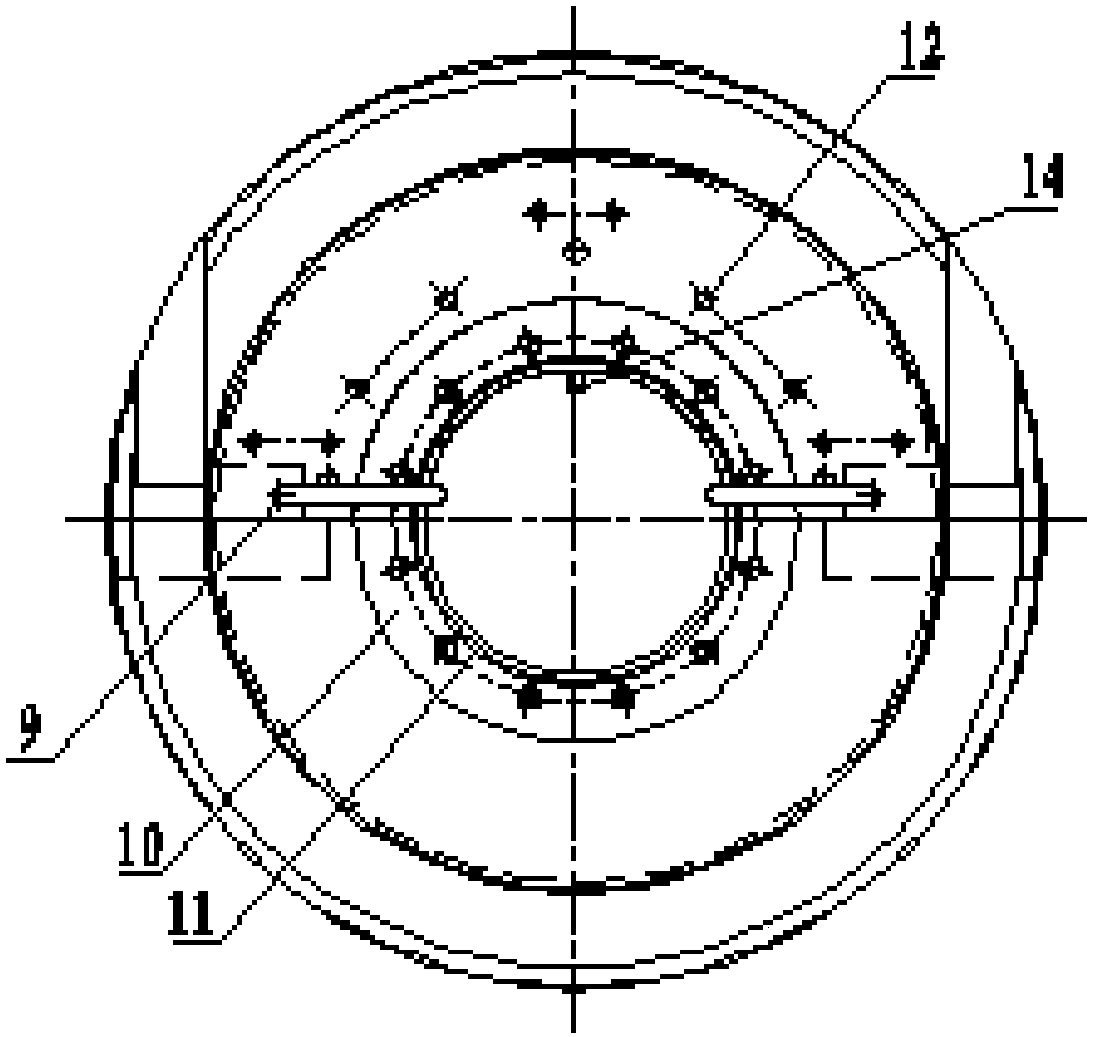

Integrated liquid rocket engine high-speed turbo pump rotor dynamic characteristics test device

A turbo pump rotor and liquid rocket technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of not being able to guarantee the concentricity of the rotor to drive the motor to the center, and it is difficult to stably increase the speed to a higher speed , interference test data acquisition accuracy and other issues, to achieve the effect of simplifying the number of adapters, good bearing lubrication effect, improving safety and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The basic idea of the present invention is: the integrated liquid rocket engine high-speed turbo pump rotor dynamic characteristic test device is composed of upper and lower tiles. The self-integrated structure consolidates the two support positions into one body, which improves the positioning accuracy and rigidity of the support. The outside of the tile is docked with the test support device through the positioning surfaces on both sides, and positioned by the positioning pin on the top of the upper tile, which can effectively ensure the alignment between the test rotor and the test device. There are 4 oil inlet holes on the side of the lower pad, and the lubricating oil can lubricate the bearing through the built-in oil circuit. The design of the oil circuit ensures the efficient and accurate lubrication of the bearing. The inside of the tile is a hollow oil return chamber, and there are two oil return holes at the bottom of the lower tile to ensure the circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com