Concrete temperature stress testing machine with ultrasonic and acoustic emission detection function

A concrete temperature and stress test technology, which is used in material analysis using sonic emission technology, solid analysis using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. Non-destructive and other problems, to achieve high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

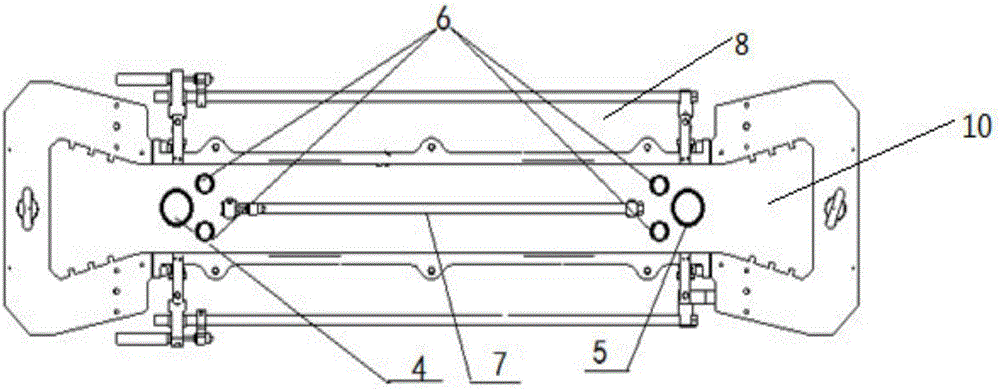

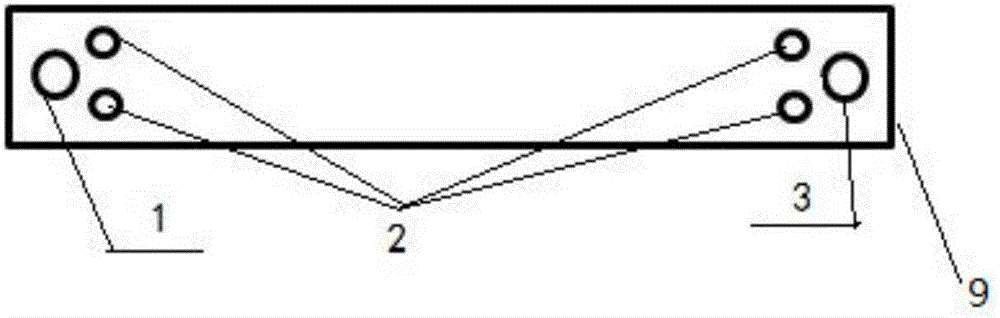

[0014] see figure 1 , figure 2 , the present invention provides a concrete temperature stress testing machine with ultrasonic and acoustic emission detection functions, including: temperature stress testing machine 8, an ultrasonic testing system including a P-wave probe and an S-wave probe, an acoustic emission system and a computing device. The ultrasonic testing system is electrically connected to the computing device. The bottom plate 9 of the temperature stress testing machine 8 is provided with a plurality of installation holes and baffles matching with the installation holes and used to fill the installation holes. In one embodiment, the mounting hole may be a circular threaded hole. The baffle is threadedly connected with the circular hole, so as to realize the opening and closing of the circular hole. During the vibrating stage, the baffle is screwed into the circular hole, and the circular hole is kept closed by the baffle; after the concrete is solidified and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com