Pressure sensor and pressure touch panel

A pressure sensor and touch panel technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc. Control experience effect, uniform response sensitivity, uniform sensing sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

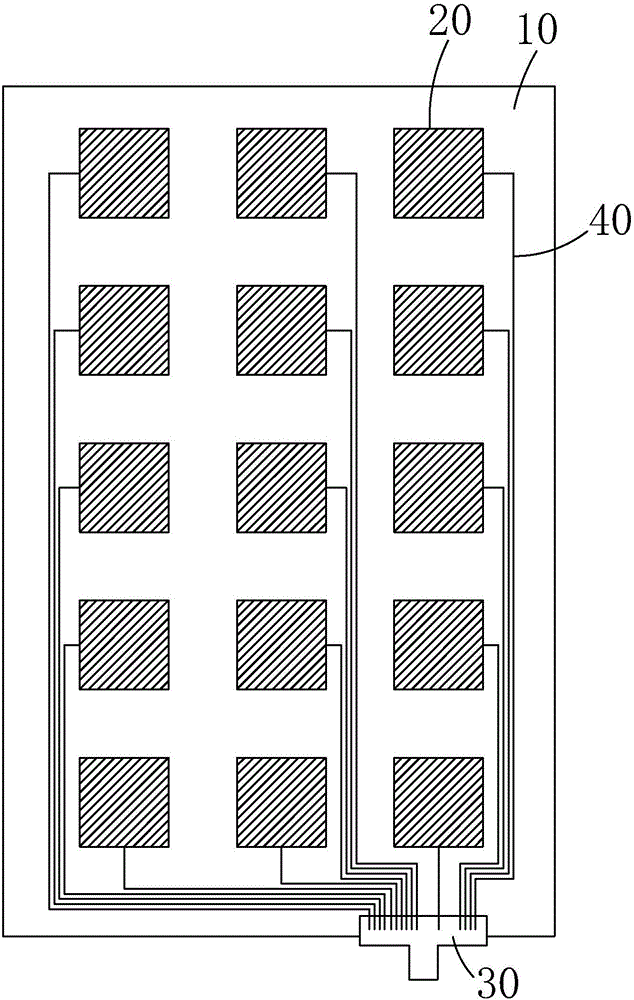

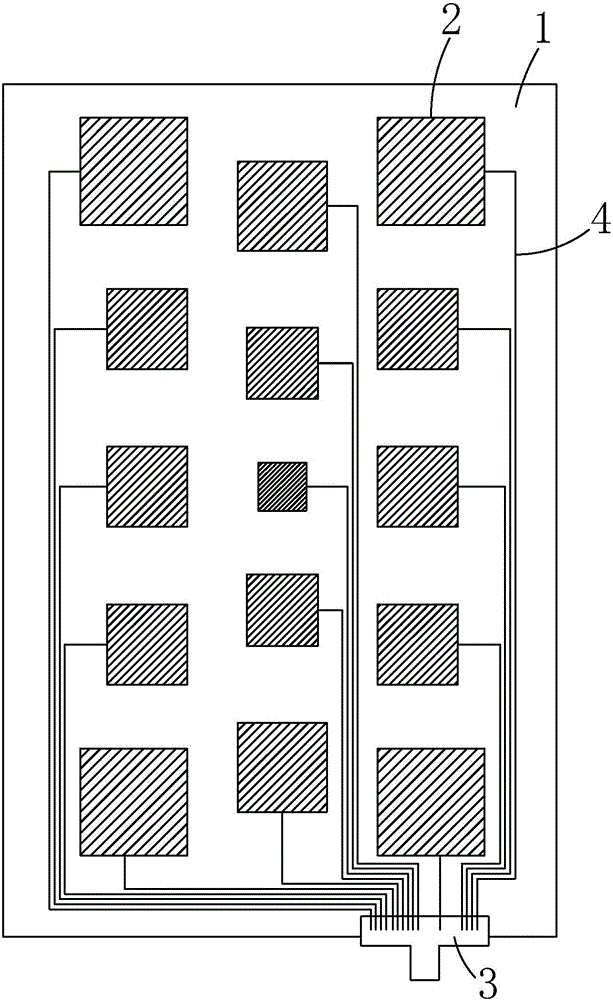

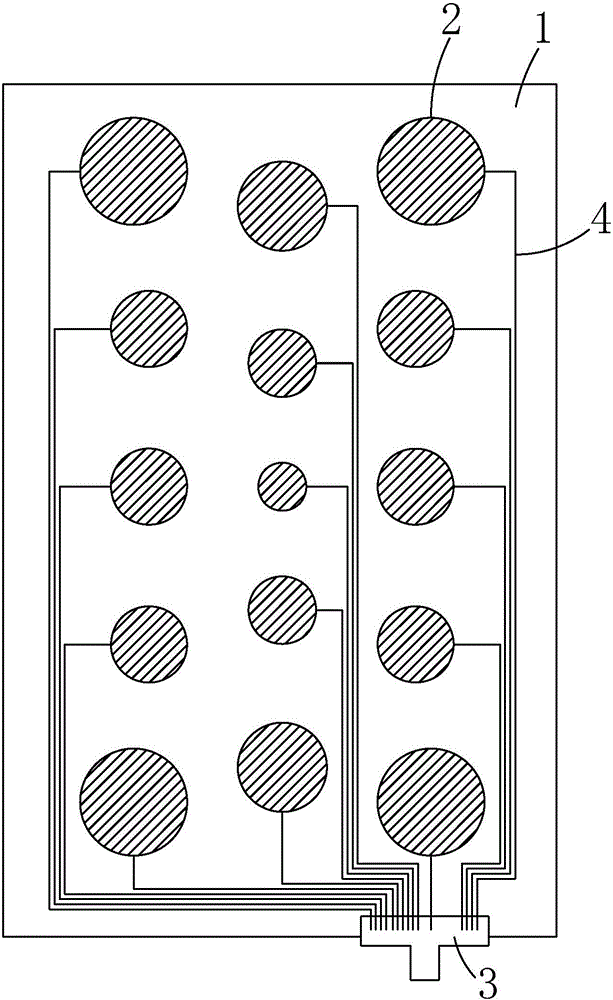

[0031] see Figure 2 to Figure 4 , the present invention provides a pressure sensor, comprising: a substrate 1, a plurality of sensing units 2 disposed on the substrate 1, disposed on the substrate 1 and respectively connected to the plurality of sensing units 2 There are several wires 4 in one-to-one correspondence, and the circuit board 3 arranged on one side of the substrate 1 .

[0032] The sensing unit 2 is connected to the circuit board 3 through the corresponding wire 4 , and transmits the sensed pressure signal to the circuit board 3 .

[0033] The plurality of sensing units 2 are arranged in a divergent form from the center of the substrate 1 to the periphery of the substrate 1;

[0034] Among the several sensing units 2, the sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com