Fusing method of 3D laser point cloud and 2D image

A two-dimensional image, three-dimensional laser technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of low calculation efficiency, large amount of data, and complicated calculation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing.

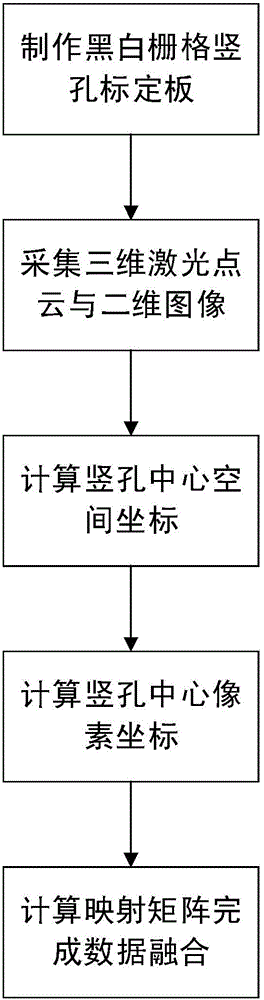

[0061] like figure 1 As shown, a fusion method of a 3D laser point cloud and a 2D image comprises the following steps:

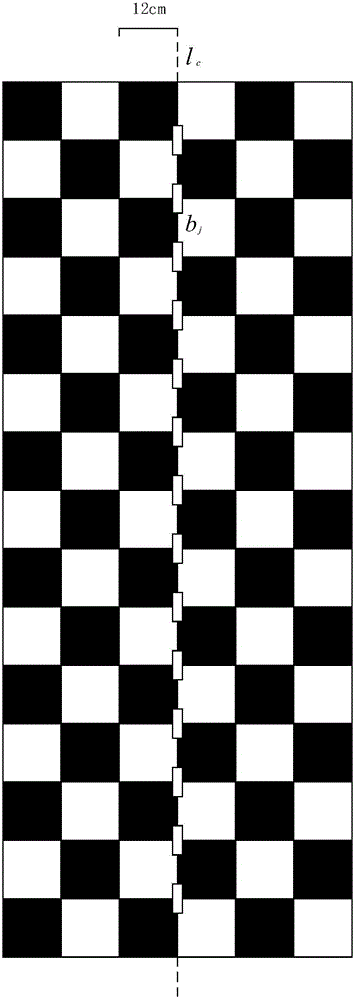

[0062] Step 1. Make a black and white grid vertical hole calibration plate. The size of the calibration plate is 180cm×72cm, and black and white square grids with a side length of 12cm are evenly distributed on it, along the center line of the calibration plate l c 14 vertical holes are evenly arranged B={b j |1≤j≤14}, the length of the vertical hole is 6cm, the width is 2cm, and the center of each vertical hole is c j (1≤j≤14) are located at the corners of the black and white grid, such as figure 2 shown.

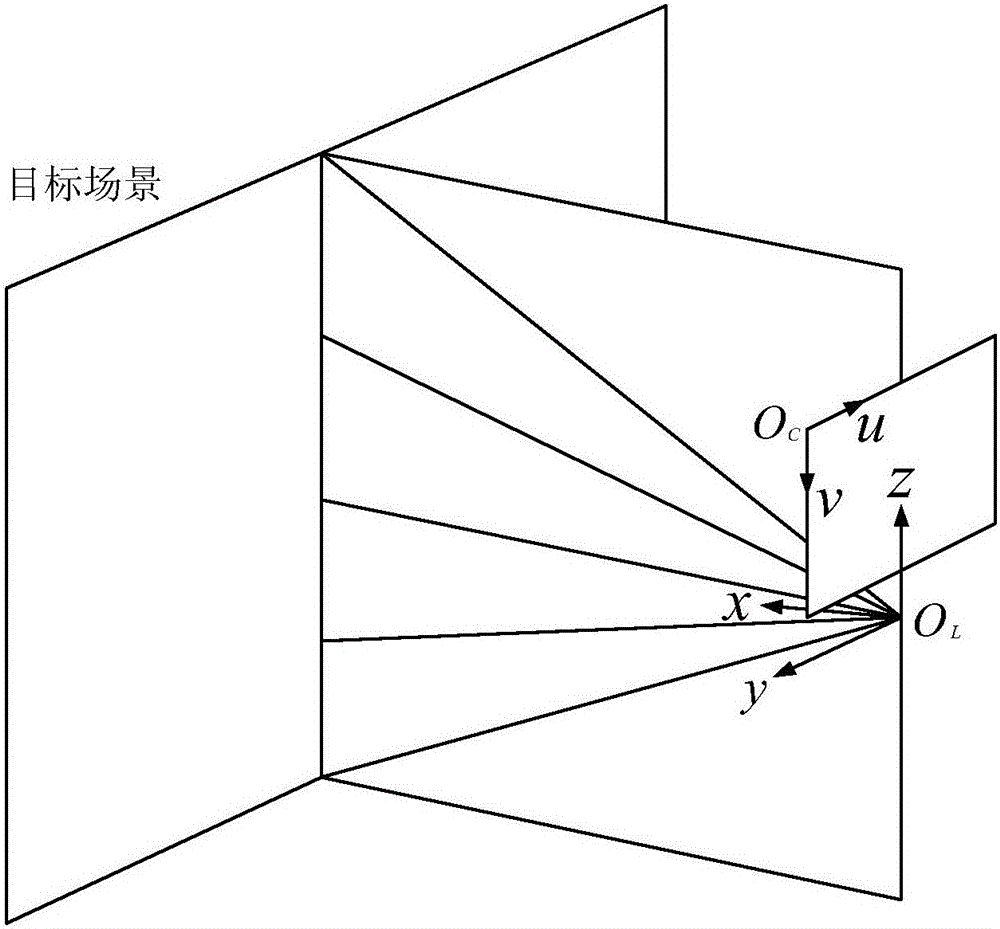

[0063] Step 2. Collect 3D laser point clouds and 2D images, fix the laser scanner and camera, and face the calibration plate vertically to the laser scanner and camera. When scanning with the laser scanner, the reflection of laser light will form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com