Windage yaw-proof Y-type composite insulator and manufacturing method thereof

A composite insulator, wind and deflection technology, applied in the field of power transmission and transformation, can solve the problems of increasing the length of the pole and tower cross arm, reducing the swing amplitude of the wire, increasing the construction cost, etc., and achieves the effects of cost saving, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

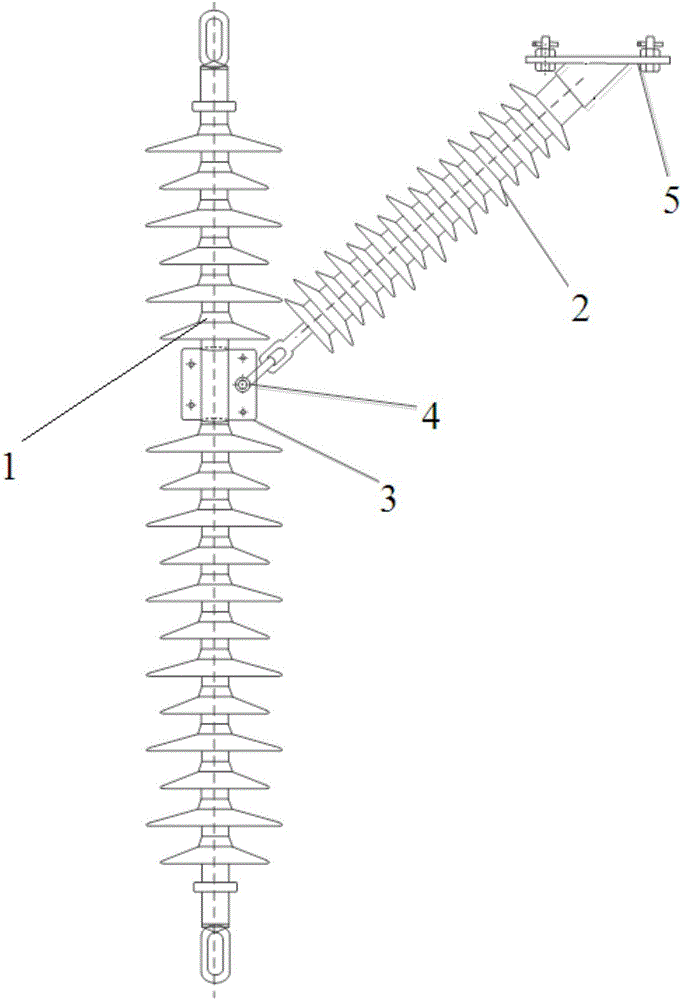

[0014] The windproof Y-type composite insulator of the present invention comprises an I-type composite insulator string 1, a post-type composite insulator string 2, a fixed connector 3 in the middle of the I-type composite insulator string 1, and one end of the post-type composite insulator string 2 It is fixed on the connector 3 by the fastener 4, and the other end of the post-type composite insulator string 2 is installed on the cross arm of the tower through the fixture 5, and the I-type composite insulator string 1 and the post-type composite insulator string 2 pass through the connector Form a Y shape with the fastener to form a fixed triangular support. The swing of the I-type composite insulator string 1 is effectively restricted, and at the same time, there is no need to change the size of the cross arm and the design of the tower head. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com