A method for laser lossless peeling-off of a flexible substrate

A flexible substrate and laser lift-off technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as unguaranteed yield and cost, threats to product yield, and damage to flexible display films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

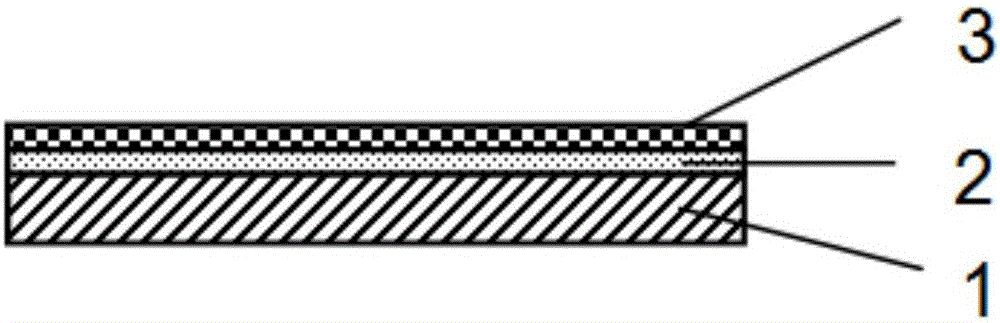

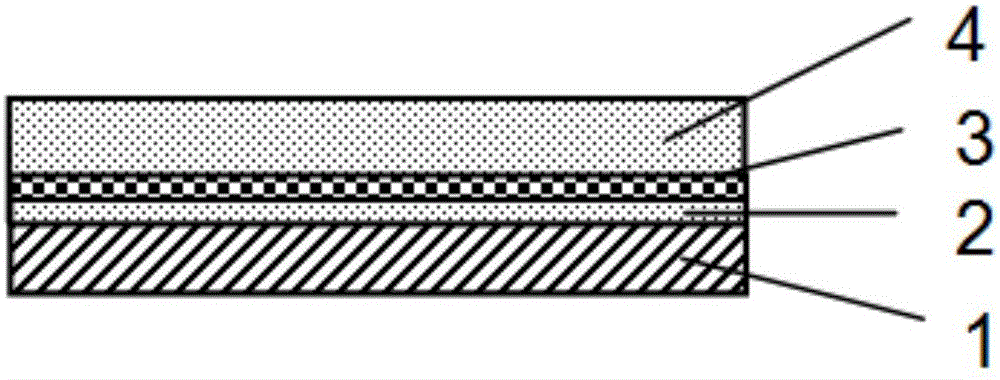

[0020] Figure 1a to Figure 1e It is a flowchart of a method for laser non-destructive peeling off of a flexible substrate according to an embodiment of the present invention.

[0021] According to the embodiment of the present invention, the method for laser non-destructive peeling off of the flexible substrate includes the following steps:

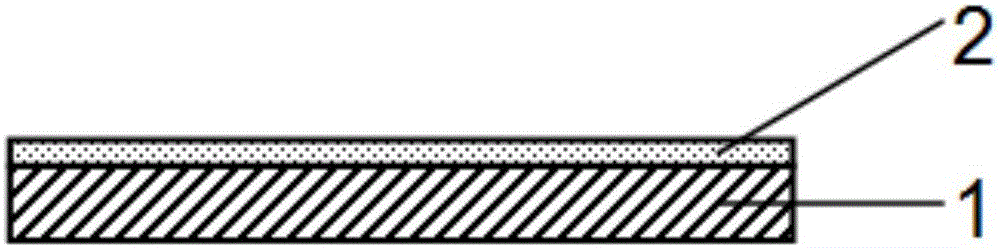

[0022] Step 1: Combine Figure 1a As shown, the glass substrate 1 is first cleaned, so as to thoroughly clean the impurities attached to the glass substrate 1 .

[0023] Then, a layer of polymer material is coated on the surface of the glass substrate 1 as the laser lift-off layer 2 . The thickness of the laser peeling layer is 10 μm˜20 μm. The material of the laser peeling layer 2 can be compared with the flexible substrate 4 ( Figure 1c ) of the same or different materials. For example, the material of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap