Filling system for operating fluid containers

A filling system, technology of working fluid, applied in the direction of machine/engine, arrangement in combination with fuel supply of internal combustion engine, exhaust gas treatment, etc., which can solve the problem of not being squeezed/cut or ripped from the fuel container or filling neck, etc., Achieving the effect of increased safety levels and low investment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the description now following, the same reference numerals designate the same components or the same features, with the result that descriptions made with respect to components in one figure also apply to other figures, so that repeated descriptions are avoided.

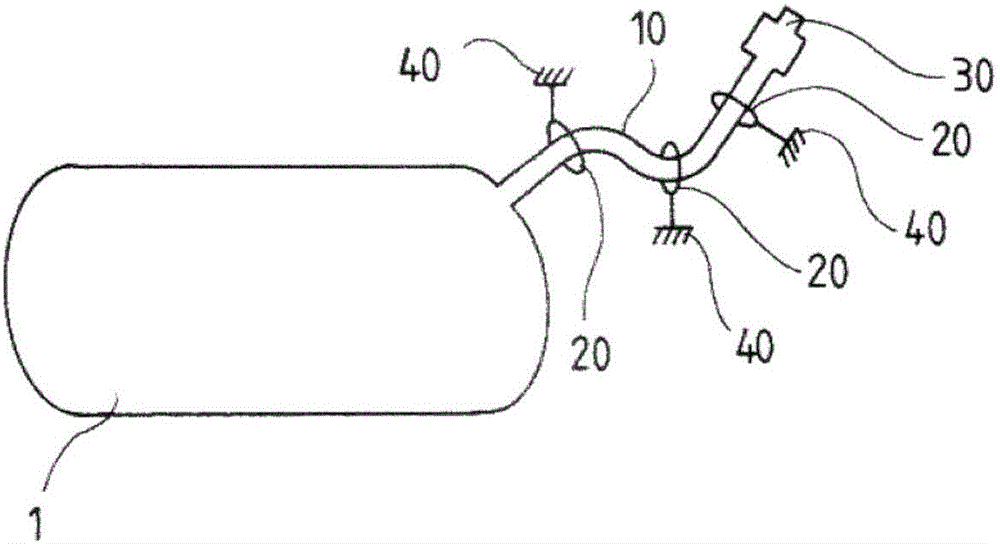

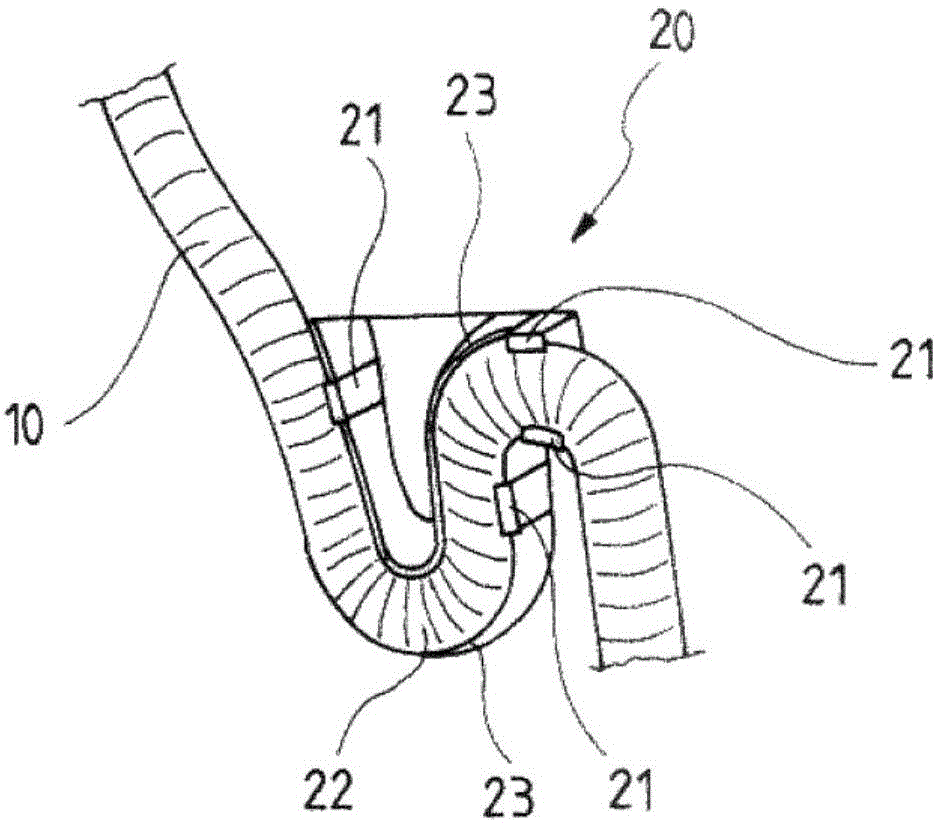

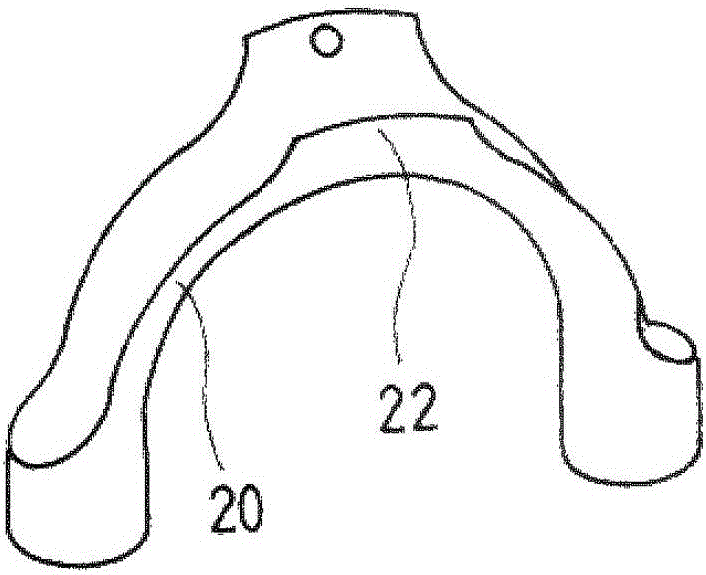

[0050] figure 1 A schematic diagram of a working fluid container 1 according to the invention and a filling system connected thereto according to the invention is shown. The working fluid container 1 is fluidically connected to a filling neck 30 via a filling hose 10 of the filling system. The filling hose 10 is fastened in the installation space of the motor vehicle by means of a plurality of filling hose holders 20 . In this case, a plurality of filling hose holders 20 are fixed at fastening points 40 in the installation space of the motor vehicle.

[0051] as from figure 1 It is obvious that since the filling hose 10 is fixed in the installation space of the motor vehicle by the filling hose holding d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap