A battery pack air-cooled cooling system

A cooling system and air-entraining technology, used in batteries, secondary batteries, battery pack components, etc., can solve the problems of insufficient cooling, uneven cooling, affecting the working efficiency and life of the battery system, and achieve the effect of structural optimization.

Active Publication Date: 2018-09-21

SYST ELECTRONICS TECH ZHENJIANG CO LTD +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Nowadays, the most commonly used cooling methods for the thermal management of electric vehicle power batteries are mainly liquid cooling and water cooling. In the cooling process of air cooling, due to the structure of the box body and the structure of the battery module module, the horizontal air direction cooling method is generally used, which is easy to form. The turbulent flow and the cooling air cannot fully contact and evenly cool each battery cell, which will lead to problems such as insufficient cooling and uneven cooling in the battery system, which will affect the working efficiency and life of the battery system.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

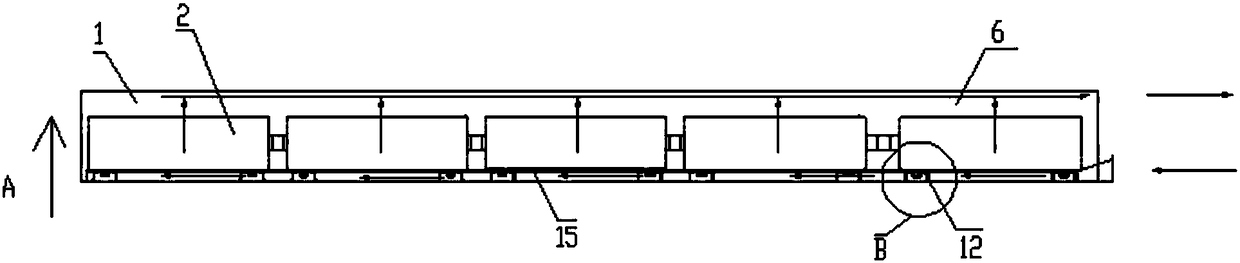

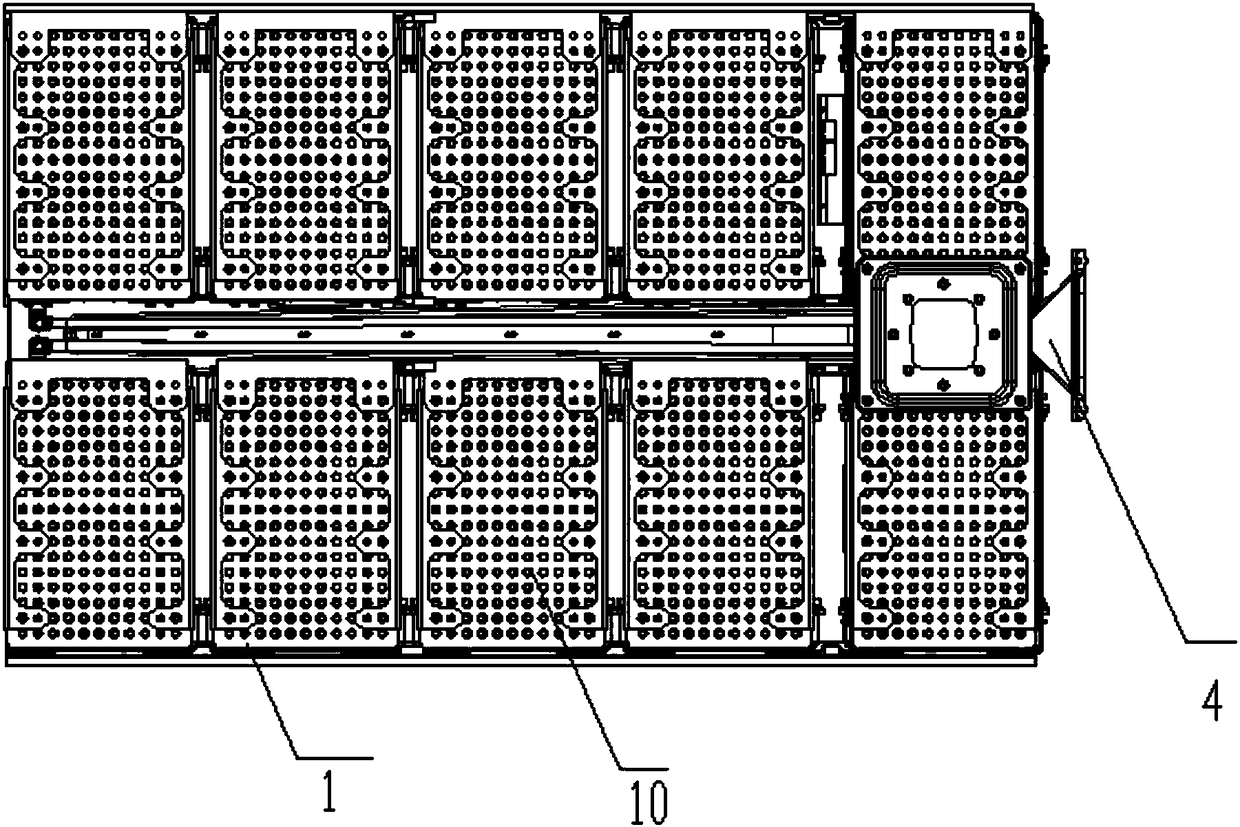

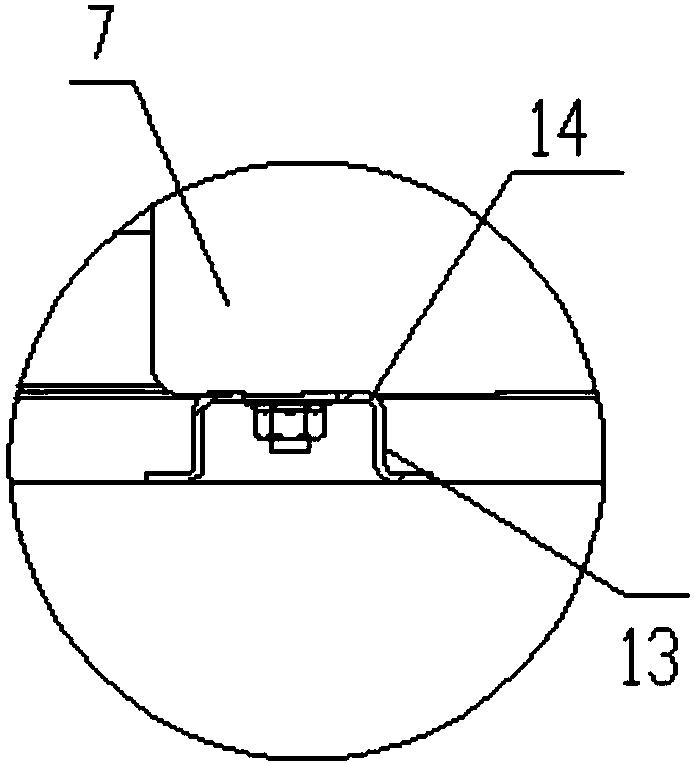

Aiming at the above problems, the present invention proposes an air-cooled cooling system for battery packs, which includes a system housing and a cell module; One end of the passage is connected to the air inlet, and there are several battery module accommodation chambers on both sides of the main air inlet passage, and the battery module accommodation chambers are symmetrically arranged in pairs with the main air inlet passage as the axis; the battery module includes a battery case body and several cell groups, each cell group consists of four cells distributed in the form of 2*2, the cell housing is provided with a number of second channels, and each second channel is connected to the cell The axes of the groups correspond to each other, which can ensure sufficient and uniform cooling. The bottom-up cooling method is more suitable for the convection principle of the air, and it is not easy to form turbulent flow, and the cooling is more uniform.

Description

technical field [0001] The invention relates to a cooling system, in particular to an air-cooled cooling system for a battery pack. Background technique [0002] Electric vehicle power batteries will seriously affect the performance and life of the battery cells in a high temperature environment, so the thermal management of the battery pack is very important. [0003] Nowadays, the most commonly used cooling methods for the thermal management of electric vehicle power batteries are mainly liquid cooling and water cooling. In the cooling process of air cooling, due to the structure of the box body and the structure of the battery module module, the horizontal air direction cooling method is generally used, which is easy to form. The turbulent flow and the cooling air cannot fully contact and evenly cool each battery cell, which will lead to problems such as insufficient cooling and uneven cooling in the battery system, which will affect the working efficiency and life of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M2/02H01M50/10

CPCH01M10/613H01M10/625H01M2220/20H01M50/10Y02E60/10

Inventor 史云福陈沈常昊

Owner SYST ELECTRONICS TECH ZHENJIANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com