A multi-channel connector

A connector and multi-channel technology, applied in the direction of connection, two-part connection device, and components of the connection device, etc., can solve the problems of complex socket and plug manufacturing process, difficult to improve product quality, and no support for quick-plug installation, etc. Simple and convenient maintenance and repair, reduce the generation of electrical contact interference sources, and maintain the effect of impedance continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

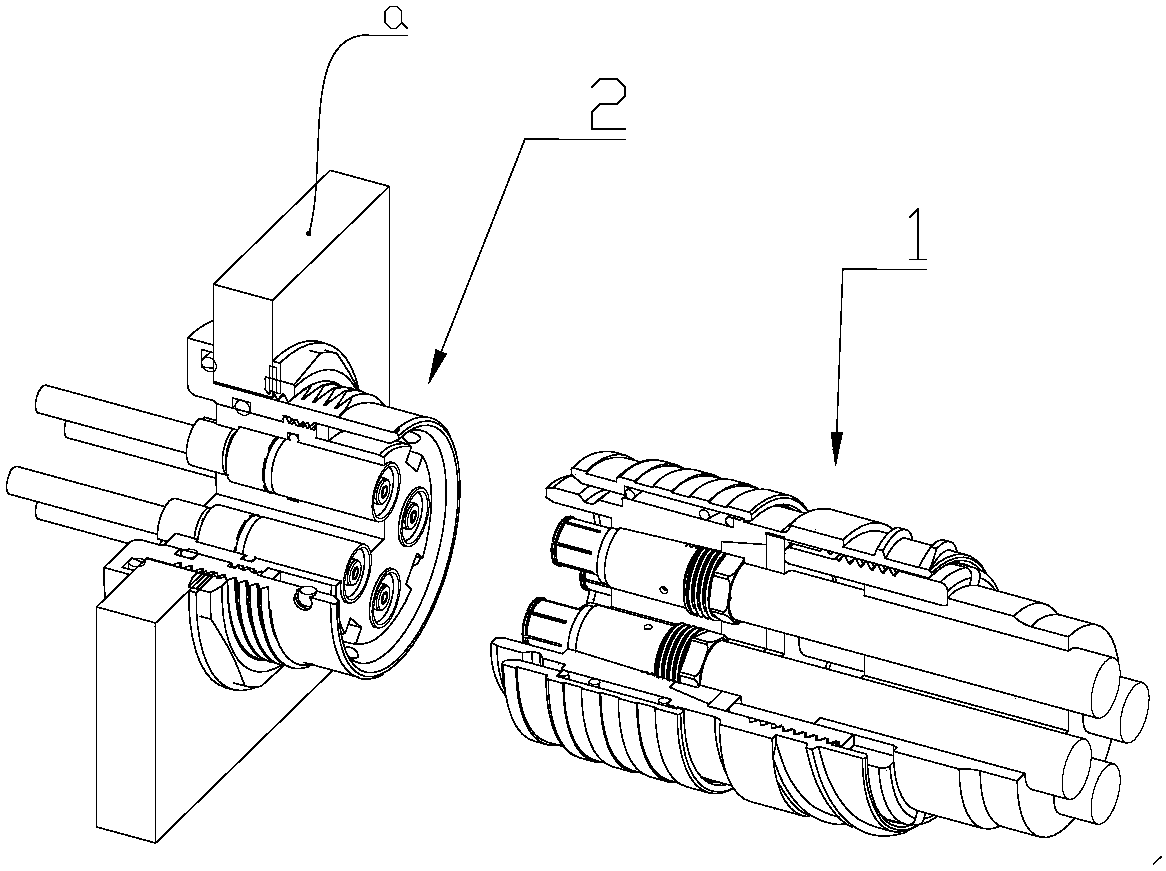

[0041] refer to Figure 1-3 , a circular multi-channel connector, including a plug 1 and a socket 2, the plug 1 is matched with the socket 2 and inserted into the communication device a.

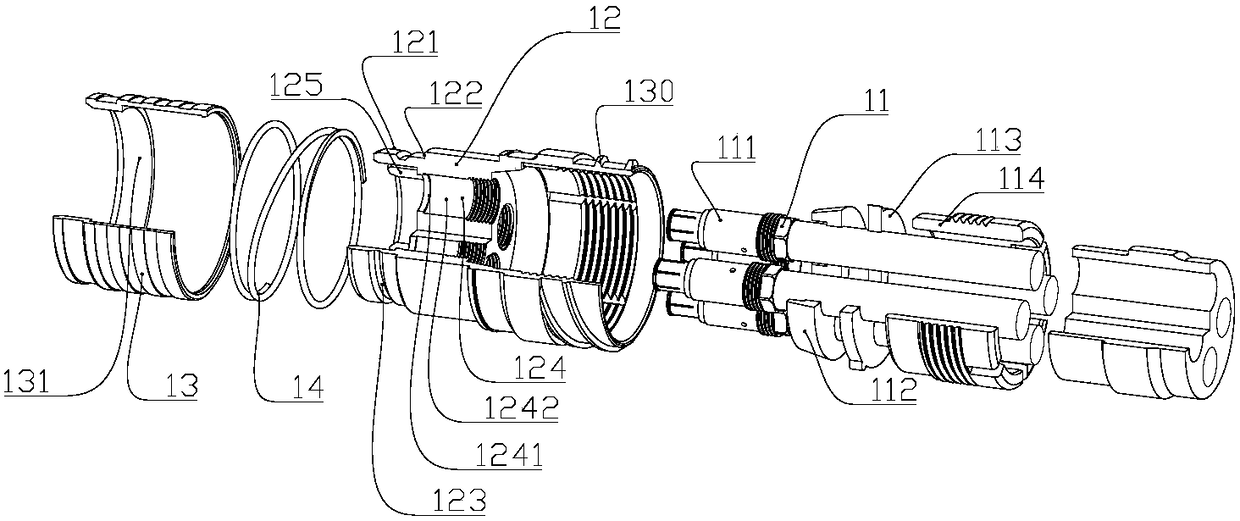

[0042] like figure 2 As shown, the plug 1 includes a needle assembly 11, a first housing 12, an unlocking sleeve 13 and an elastic member 14; the needle assembly 11 is inserted in the first housing 12, the first housing 12 is inserted in the unlocking sleeve 13, and the elastic member 14 It is installed between the first shell 12 and the unlocking sleeve 13 . The first shell 12, the unlocking sleeve 13, and the elastic member 14 are all circular structures.

[0043] like Figure 7 As shown, there are at least two groups of needle assemblies 11, and each group of needle assemblies 11 includes a needle contact 111, and also includes a porous sealing gasket 112, a porous pressing plate 113 and a fastening screw sleeve 114; a porous sealing gasket 112, a porous pressing plate 113 and a tight...

Embodiment 2

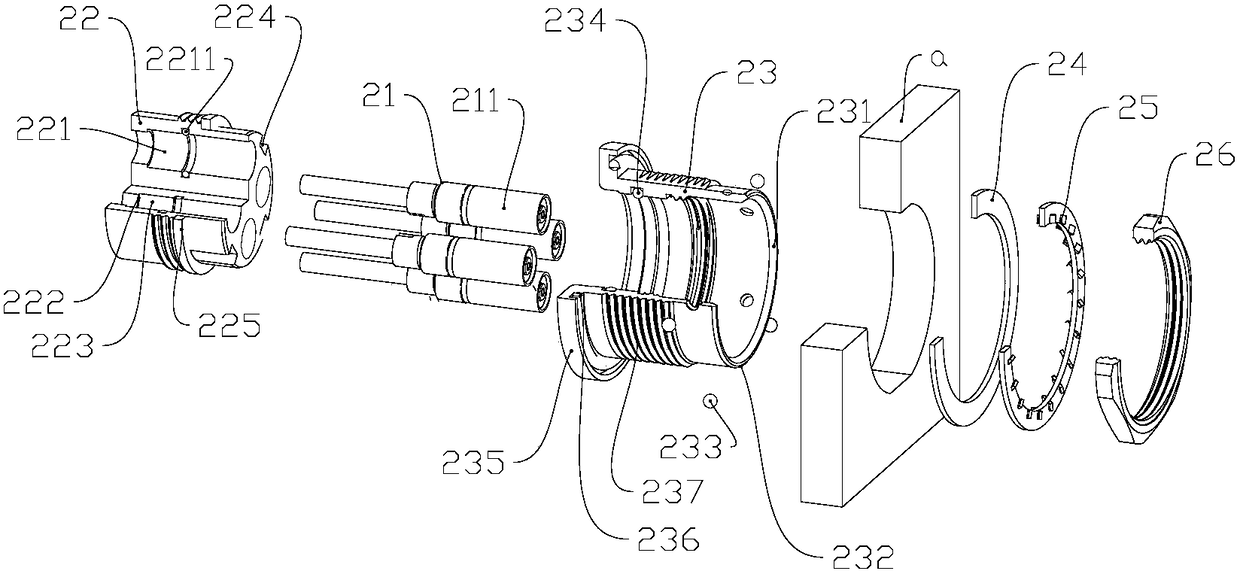

[0054] like Figure 4-6 As shown, a square multi-channel connector includes a plug 1 and a socket 2. The plug 1 is mated with the socket 2 and inserted into the communication device a.

[0055] The plug 1 includes a needle assembly 11, a first housing 12, an unlocking sleeve 13 and an elastic member 14; the needle assembly 11 is inserted side by side in the first housing 12, the first housing 12 is inserted in the unlocking sleeve 13, and the elastic member 14 is mounted on Between the first shell 12 and the unlocking sleeve 13 . The structures of the needle assembly 11 and the hole assembly 21 are the same as those of the first embodiment. The first shell 12, the unlocking sleeve 13, and the elastic member 14 are all rectangular structures. In addition, compared with the embodiment 1, the plug 1 of this embodiment has no primary key and secondary key, and the socket 1 has no primary keyway corresponding to the primary key and secondary key. , The structure of the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com